Microwave silicon carbide ceramics heating element and preparation method thereof

A ceramic heating element and microwave silicon carbide technology, applied in the field of ceramic materials, can solve the problems of insufficient heating speed and energy conversion efficiency, unsatisfactory heating effect, and difficulty in wide application, etc., and achieve good microwave absorption performance, Good practical value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

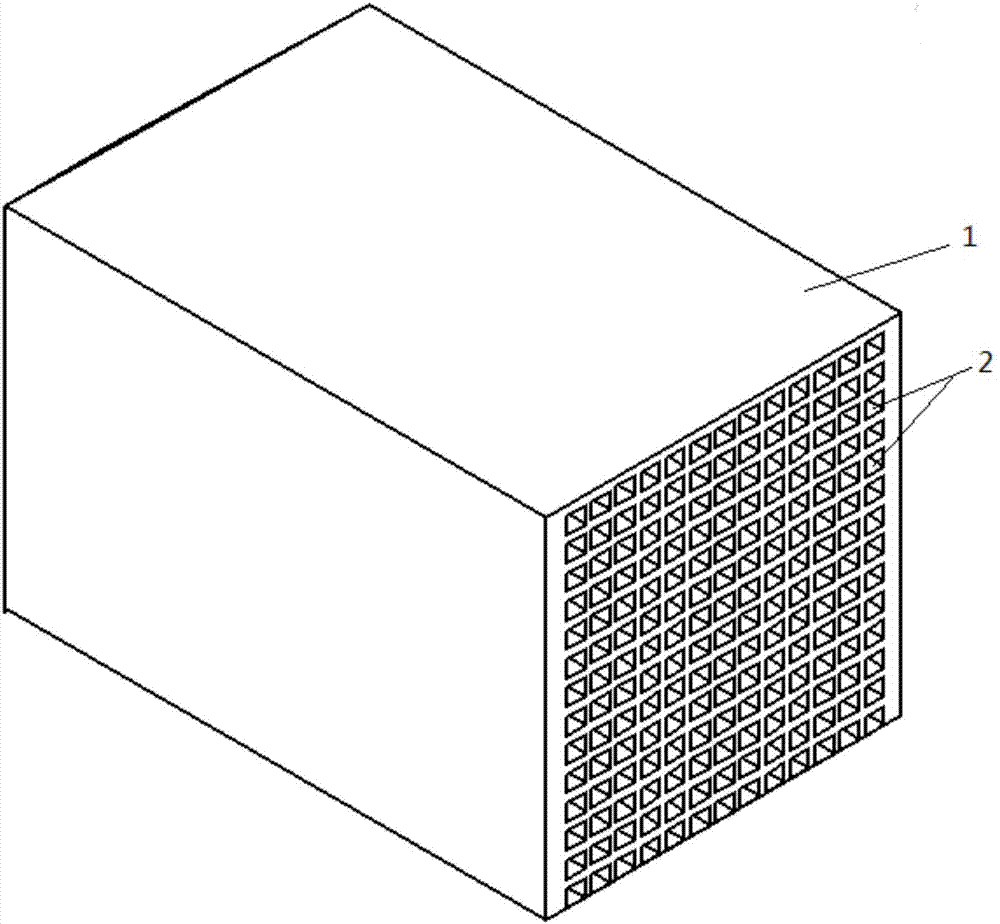

Image

Examples

preparation example Construction

[0027] The preparation process of the ceramic heating element comprises the following steps:

[0028] a. Preparation of wave-absorbing ceramic raw materials: Weigh each component in the wave-absorbing ceramic powder in proportion, and add each component into a Raymond mill to grind and pulverize to 1000 mesh powder, and then add the obtained powder into viscose Put the binder into a centrifugal mixer, stir and mix for 0.5-1 hour, and obtain a uniformly mixed wave-absorbing ceramic raw material;

[0029] b. Pressure molding: Put the wave-absorbing ceramic raw material obtained in step a into a mold and press it directly with a hydraulic press to form it. The molding pressure is 25-50 MPa, and the pressure stabilization time lasts for 1.5-2.5 minutes to obtain a ceramic body;

[0030] c. Stylized drying: the ceramic body obtained in step b is left to stand for not less than 24 hours to solidify and form, and then microwave drying is used after standing, and the drying environmen...

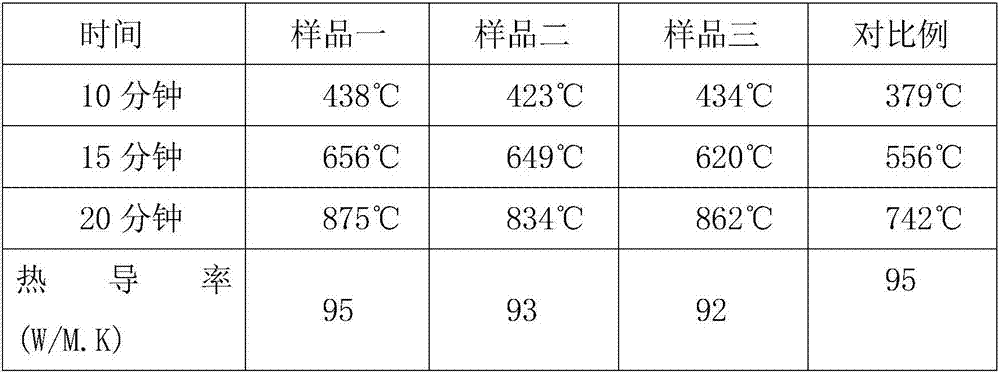

Embodiment 1

[0033] Weigh the components in the microwave-absorbing ceramic powder in proportion: 73wt% of silicon carbide, 1wt% of aluminum oxide, 1wt% of zirconia, 20wt% of ferric oxide, 1wt% of hafnium dioxide, 1wt% of silicon dioxide, three Diyttrium oxide 1wt%, lanthanum trioxide 2wt%, the above components are added to a Raymond mill, ground and pulverized to a 1000 mesh powder, and then the obtained powder is added to a binder that is a high temperature resistant glue. The addition amount is 6wt% of the wave-absorbing ceramic powder, put into a centrifugal mixer, stir and mix for 1 hour, and prepare the wave-absorbing ceramic raw material. The obtained wave-absorbing ceramic raw material is pressed into a mold and pressurized by a hydraulic press to obtain a ceramic green body. The molding pressure is 25 MPa, and the pressure stabilization time lasts for 2 minutes. Then the obtained ceramic green body is left to stand and solidified for not less than 24 hours, microwave-dried at 90° ...

Embodiment 2

[0035]Weigh the components in the microwave-absorbing ceramic powder in proportion: 70wt% silicon carbide, 2wt% aluminum oxide, 2wt% zirconia, 21wt% ferric oxide, 1wt% hafnium dioxide, 1wt% silicon dioxide, three Diyttrium oxide 1wt%, lanthanum trioxide 2wt%, the above-mentioned components are ground and pulverized into a 1000-mesh powder in a Raymond mill, and then the obtained powder is added to a binder that is a high-temperature-resistant glue. The addition amount is 7wt% of the wave-absorbing ceramic powder, put into a centrifugal mixer, stir and mix for 0.5h, and prepare the wave-absorbing ceramic raw material. The obtained wave-absorbing ceramic raw material is pressed into a mold and pressurized by a hydraulic press to obtain a ceramic green body. The molding pressure is 25 MPa, and the pressure stabilization time lasts for 1.5 minutes. Then the obtained ceramic green body is left to stand and solidified for not less than 24 hours, microwave-dried at 100° C., and coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com