A kind of recombinant bacteria for immobilizing carbon dioxide to synthesize succinic acid and its construction method and application

A technology of carbon dioxide and recombinant bacteria, applied in the field of genetic engineering, can solve the problems of increasing production costs in anaerobic environment, achieve broad development prospects and application potential, avoid excessive dependence, and reduce the effect of temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Construction of recombinant bacteria that fix carbon dioxide and synthesize succinic acid

[0054] 1)-2) Construction of vector pACYCDuet-accADBC-pcs

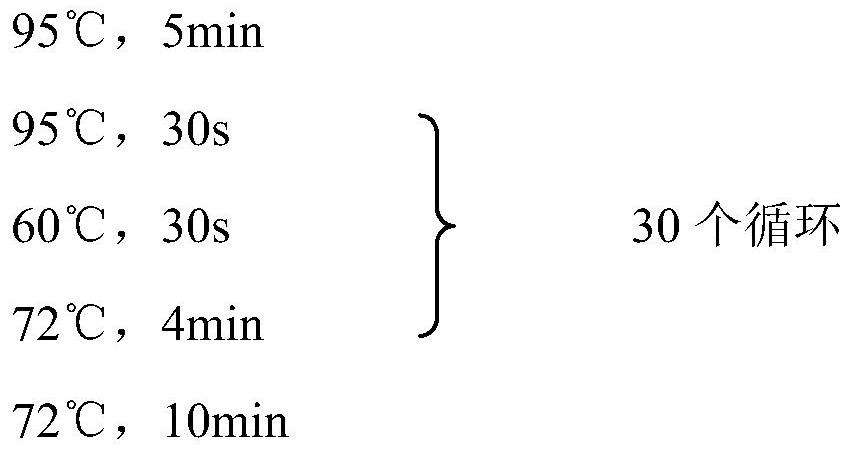

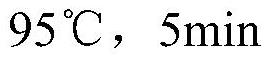

[0055] 1) Obtain the gene accADBC of acetyl-CoA carboxylase derived from Escherichia coli (the gene IDs of each subunit in NCBI are accA: 944895, accB: 947758, accC: 947761, accD: 946796), and use the gene of Escherichia coli The genome was used as a template and obtained by PCR amplification (primers: 5'-caggatccgatgagtctgaatttcctt-3' and 5'-CGGAATTCTTATTTTCCTGAAGACCGAGTTT-3'). The specific amplification procedure is as follows:

[0056]

[0057] After the PCR, 1% (wt / v) agarose gel electrophoresis was performed, and the target fragment with a size of about 4000 bp was recovered by using a recovery kit (OMEGA GelExtraction Kit).

[0058] The obtained accADBC gene fragment and plasmid pACYCDuet-1 were double digested with BamHI and XhoI restriction endonucleases at 37°C for 3.5 hours, and the digested produ...

Embodiment 2

[0091] Embodiment 2 fermentation produces succinic acid

[0092] The monoclonal engineered strain obtained in Example 1 is activated in LB culture, and the seed liquid after activation is inoculated into a 500mL block containing 100mL of the basic improved liquid medium by the volume ratio of seed liquid: basic improved liquid medium 1:100. Plate shake flasks (containing 100 μg·mL-1 ampicillin and 100 μg·mL-1 chloramphenicol) were shaken at 37°C and 180 rpm. OD 600 When reaching about 0.6, the temperature was adjusted to 30°C, and 0.05mM IPTG was added for induction. The pH was adjusted to about 7 with ammonia water every 12 hours, and the fermentation was terminated 48 hours after the initial induction.

[0093] Product detection:

[0094] After the fermentation, take the fermented liquid, centrifuge at 10000rpm for 2min, and filter the supernatant through a 0.22μm water phase filter membrane to a liquid phase autosampler bottle, and perform qualitative detection by liquid...

Embodiment 3

[0096] Embodiment 3 fermentation produces succinic acid

[0097] The single clone of the engineering strain obtained in Example 1 is activated in LB culture, and the seed liquid after activation is inoculated into the 500mL block containing the basic improved liquid medium of 100mL by the volume ratio of seed liquid: basic improved liquid medium 2:100 Shake flasks (containing 100 μg·mL-1 ampicillin and 100 μg·mL-1 chloramphenicol) were shaken at 37°C and 220 rpm. OD 600 When reaching about 0.8, the temperature was adjusted to 33°C, and 0.1 mM IPTG was added for induction. The pH was adjusted to about 7 with ammonia water every 12 hours, and the fermentation was terminated 24 hours after the initial induction.

[0098] After the fermentation, take the fermented liquid, centrifuge at 10000rpm for 2min, and filter the supernatant through a 0.22μm water phase filter membrane to a liquid phase autosampler bottle, and perform qualitative detection by liquid chromatography-triple q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com