Preparation method for nickel hydroxide/nickel/graphene composite hydrogen evolution electrode with hierarchical structure

A technology of hydrogen evolution electrode and hierarchical structure, which is applied in the direction of electrodes, electrode shapes/types, electrolytic coatings, etc., can solve the problems of large distances in hydrogen evolution performance, and achieve the effects of preventing metal agglomeration, good stability, and enhancing binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

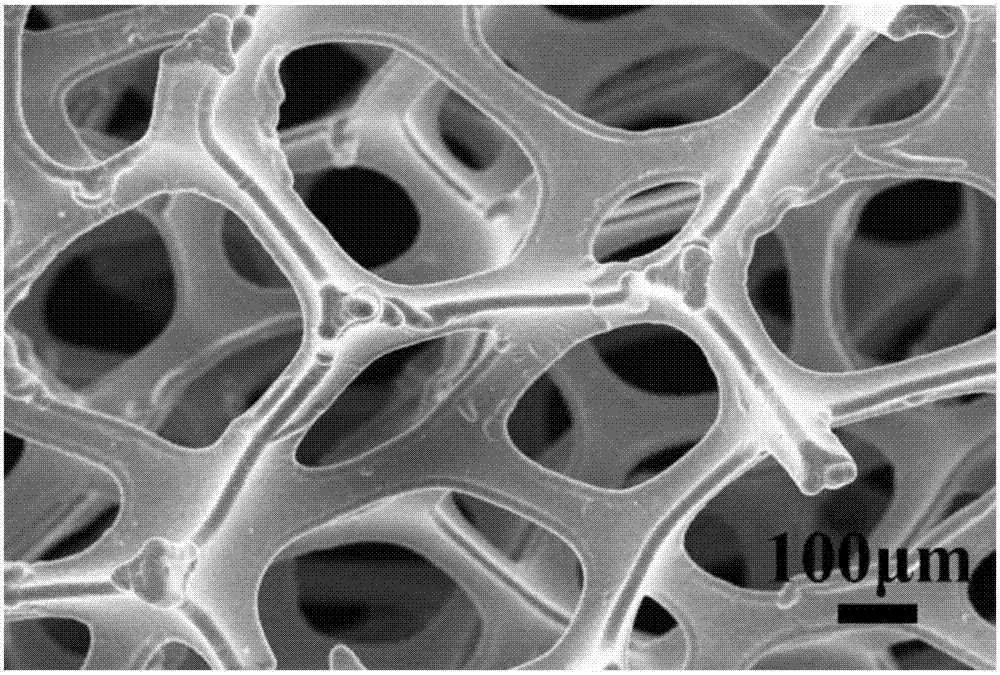

[0030] (1) Pretreatment of nickel foam substrate

[0031] Before electrodeposition, immerse the foamed nickel substrate in a beaker filled with deionized water, and ultrasonically treat it for 5 minutes; then put the foamed nickel into 3M HCl solution for acidification for 30 seconds, then wash it with deionized water until neutral, and dry it for later use.

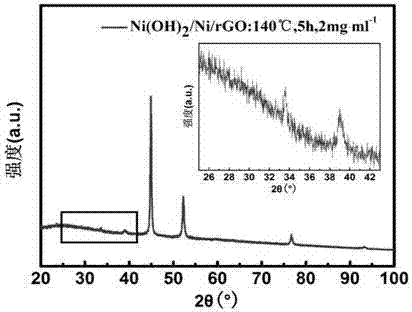

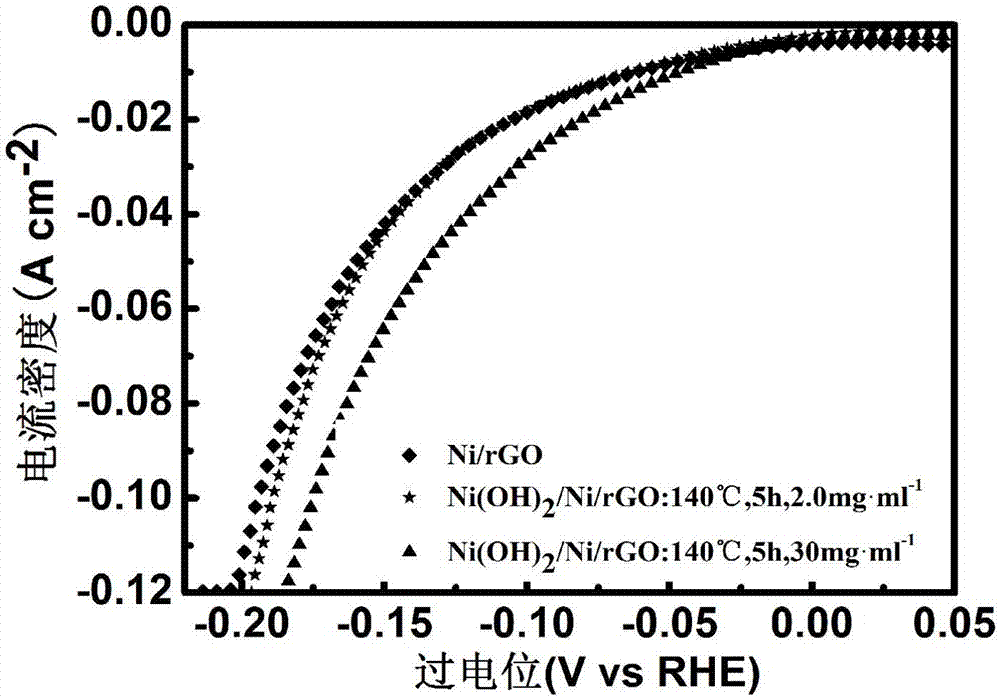

[0032] (2) Preparation of Ni / rGO composite electrodes by high-gravity electrodeposition

[0033] With distilled water as solvent, every liter of plating solution contains 350g of nickel sulfamate, 10g of nickel chloride, 30g of ammonium chloride and 1.0g of graphene oxide, and the pH value of the plating solution is 3.8. After 2 hours of treatment under power, a uniform, dark green mixed solution was obtained. The high-gravity electrodeposition process is carried out in a cylindrical reactor, and the substrate processed in step (1) is fixed on the inner wall of the cylindrical reactor as the electrodeposition cathode, a...

Embodiment 2

[0039] (1) Pretreatment of nickel foam substrate

[0040] Before electrodeposition, immerse the foamed nickel substrate in a beaker filled with deionized water, and ultrasonically treat it for 5 minutes; then put the foamed nickel into 3M HCl solution for acidification for 30 seconds, then wash it with deionized water until neutral, and dry it for later use.

[0041] (2) Preparation of Ni / rGO composite electrodes by high-gravity electrodeposition

[0042] With distilled water as solvent, every liter of plating solution contains 350g of nickel sulfamate, 10g of nickel chloride, 30g of ammonium chloride and 1.0g of graphene oxide, and the pH value of the plating solution is 3.8. After 2 hours of treatment under power, a uniform, dark green mixed solution was obtained. The high-gravity electrodeposition process is carried out in a cylindrical reactor, and the substrate processed in step (1) is fixed on the inner wall of the cylindrical reactor as the electrodeposition cathode, a...

Embodiment 3

[0048] (1) Pretreatment of nickel foam substrate

[0049] Before electrodeposition, immerse the foamed nickel substrate in a beaker filled with deionized water, and ultrasonically treat it for 5 minutes; then put the foamed nickel into 3M HCl solution for acidification for 30 seconds, then wash it with deionized water until neutral, and dry it for later use.

[0050] (2) Preparation of Ni / rGO composite electrodes by high-gravity electrodeposition

[0051] With distilled water as solvent, every liter of plating solution contains 350g of nickel sulfamate, 10g of nickel chloride, 30g of ammonium chloride and 1.0g of graphene oxide, and the pH value of the plating solution is 3.8. After 2 hours of treatment under power, a uniform, dark green mixed solution was obtained. The high-gravity electrodeposition process is carried out in a cylindrical reactor, and the substrate processed in step (1) is fixed on the inner wall of the cylindrical reactor as the electrodeposition cathode, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com