Treatment method and treatment apparatus for standard discharging of cold-rolled dilute alkali wastewater

A technology of dilute alkali wastewater and its treatment method, which is applied in the field of water treatment and can solve problems such as environmental pollution of cold-rolled dilute alkali wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

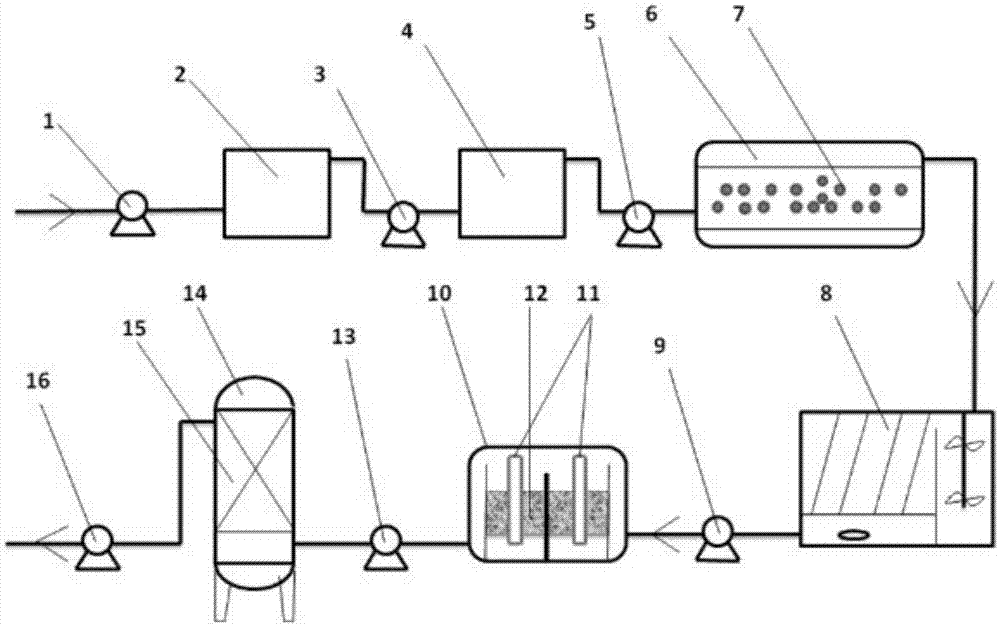

[0049] A standard treatment process system for cold-rolled dilute alkali wastewater, water inlet pump, PH rough adjustment tank, adjustment tank water pump, pH fine adjustment tank, biochemical tank water pump, aerobic biochemical tank, multi-faceted hollow ball packing, inclined plate sedimentation tank, reactor Lifting pump, ultraviolet photoreactor, ultraviolet light source, ultraviolet light active catalyst, adsorption tower lifting pump, adsorption tower, pitch-based mesophase activated carbon, water outlet pump.

[0050] The water quality pH of the cold rolling dilute alkali wastewater is 11.6, the total suspended solids is 415 mg / L, and the COD is 2950 mg / L.

[0051] The cold rolling dilute alkali wastewater enters the pH rough adjustment tank through the water inlet pump. The PH of the influent water is 11.6, and the concentration of 8% calcium hydroxide is added to the PH rough adjustment tank. The residence time of the wastewater in the pH rough adjustment tank is 9 ...

Embodiment 2

[0063] A standard treatment process system for cold-rolled dilute alkali wastewater, water inlet pump, PH rough adjustment tank, adjustment tank water pump, pH fine adjustment tank, biochemical tank water pump, aerobic biochemical tank, multi-faceted hollow ball packing, inclined plate sedimentation tank, reactor Lifting pump, ultraviolet photoreactor, ultraviolet light source, ultraviolet light active catalyst, adsorption tower lifting pump, adsorption tower, pitch-based mesophase activated carbon, water outlet pump.

[0064] The water quality pH of the cold rolling dilute alkali wastewater is 10.7, the total suspended solids is 339 mg / L, and the COD is 2330 mg / L.

[0065] The cold rolling dilute alkali wastewater enters the pH rough adjustment tank through the water inlet pump. The PH of the influent water is 10.7, and calcium hydroxide with a concentration of 6% is added to the rough pH adjustment tank. The residence time of the wastewater in the rough pH adjustment tank is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com