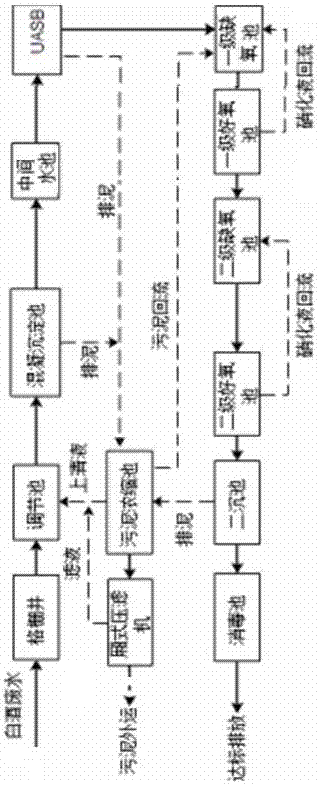

Baijiu brewing wastewater treatment system

A technology for brewing wastewater and treatment system, which is used in food industry wastewater treatment, multi-stage water treatment, water/sewage treatment and other directions to achieve the effects of reducing floor space, stable treatment effect and low process operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The invention provides a liquor brewing wastewater treatment system. The wastewater is collected by a pipe network and then collected into a grid well for pretreatment. After removing the distiller’s grains and large particles of suspended matter in the wastewater, it is lifted by a lift pump to a regulating tank to balance the water quality and volume; The wastewater in the adjustment tank flows into the coagulation sedimentation tank to remove fine suspended solids and colloidal particles, and the coagulation sedimentation tank is added with coagulants polyacrylamide and polyaluminum chloride. The concentrations of polyacrylamide and polyaluminum chloride are respectively 15g / m 3 And 150g / m 3 , Use the adsorption and coagulation effect of the coagulant to remove the fine suspended solids and colloidal particles in the wastewater, while adding sodium hydroxide to adjust the pH of the wastewater to 7; the wastewater in the coagulation sedimentation tank overflows into the ...

Embodiment 2

[0053] The invention provides a liquor brewing wastewater treatment system. The wastewater is collected by a pipe network and then collected into a grid well for pretreatment. After removing the distiller’s grains and large particles of suspended matter in the wastewater, it is lifted by a lift pump to a regulating tank to balance the water quality and volume; The wastewater in the adjustment tank flows into the coagulation sedimentation tank to remove fine suspended solids and colloidal particles, and the coagulation sedimentation tank is added with coagulants polyacrylamide and polyaluminum chloride. The concentrations of polyacrylamide and polyaluminum chloride are respectively 20g / m 3 And 200g / m 3 , Use the adsorption and coagulation of the coagulant to remove the fine suspended solids and colloidal particles in the wastewater, while adding potassium hydroxide to adjust the pH of the wastewater to 7.5; the wastewater in the coagulation sedimentation tank overflows into the in...

Embodiment 3

[0056] The invention provides a liquor brewing wastewater treatment system. The wastewater is collected by a pipe network and then collected into a grid well for pretreatment. After removing the distiller’s grains and large particles of suspended matter in the wastewater, it is lifted by a lift pump to a regulating tank to balance the water quality and volume; The wastewater in the adjustment tank flows into the coagulation sedimentation tank to remove fine suspended solids and colloidal particles, and the coagulation sedimentation tank is added with coagulants polyacrylamide and polyaluminum chloride. The concentrations of polyacrylamide and polyaluminum chloride are respectively 22g / m 3 And 200g / m 3 , Use the adsorption and coagulation of the coagulant to remove the fine suspended solids and colloidal particles in the wastewater, and add sodium hydroxide to adjust the pH of the wastewater to 8; the wastewater in the coagulation sedimentation tank overflows into the intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com