Ultrahigh molecular weight polyethylene simulation ice plate

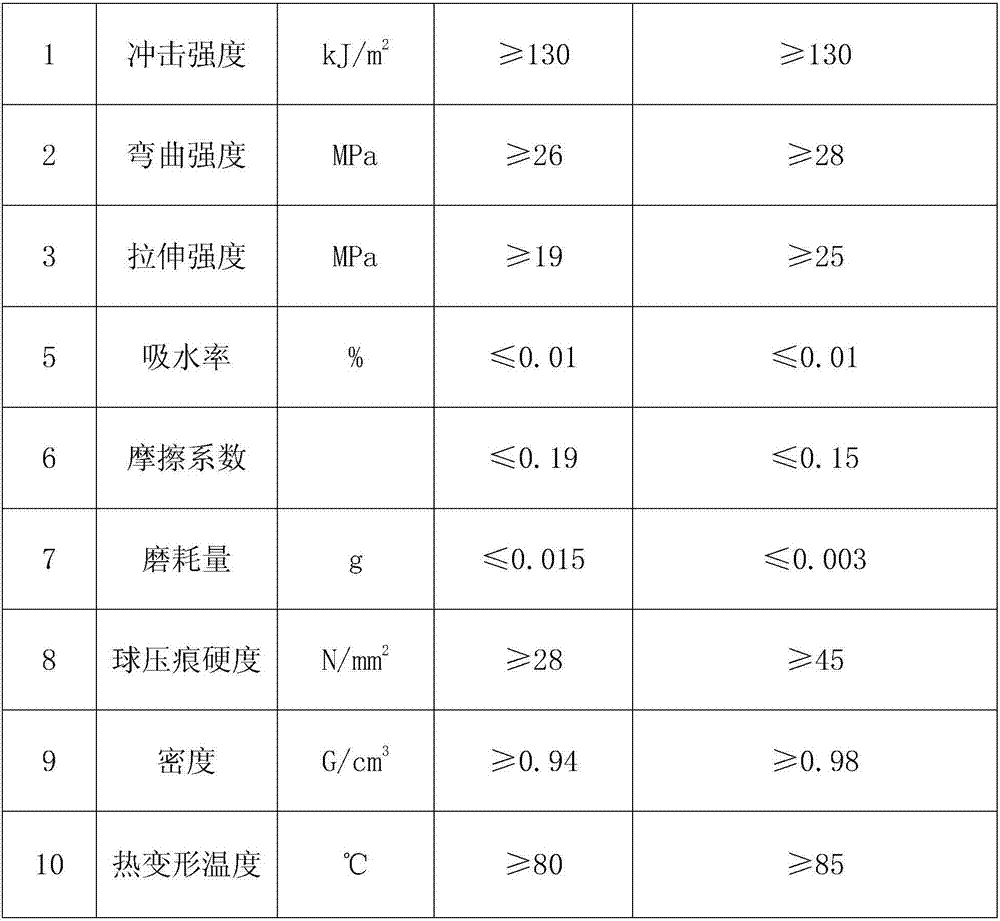

A technology of ultra-high molecular weight and polyethylene, which is applied in the field of simulated ice boards, can solve the problems that have not been discovered, such as low thermal deformation temperature, low surface hardness, and large expansion coefficient, and achieve excellent performance-price ratio, easy processing and molding, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An ultra-high molecular weight polyethylene simulated ice board is characterized in that the simulated ice board is composed of the following materials by weight: 80 parts of ultra-high molecular weight polyethylene, 0.3 parts of coupling agent, 1 part of lubricant, glass beads or talc 5 parts of powder, 0.003 part of fluorescent whitening agent OB, 0.4 part of ultraviolet absorber, 0.1 part of antioxidant, 0.2 part of lubricant microsphere, 0.1 part of mineral oil microsphere, 0.7 part of nucleating agent;

[0027] Wherein, described antioxidant is B215 antioxidant, and this antioxidant is made up of antioxidant 1010 and antioxidant 168, and the proportioning of antioxidant 1010 and antioxidant 168 is 4:6; Described Lubricant microspheres are micronano polyethylene wax solid microspheres prepared by electrospinning process, the mineral oil microspheres are prepared by white oil electrospinning process, and the glass microspheres and nucleating agent are obtained by spra...

Embodiment 2

[0030] An ultra-high molecular weight polyethylene simulated ice board is characterized in that the simulated ice board is composed of the following materials by weight: 100 parts of ultra-high molecular weight polyethylene, 2 parts of coupling agent, 3 parts of lubricant, glass beads or talc 20 parts of powder, 0.02 parts of fluorescent whitening agent OB, 1 part of ultraviolet absorber, 0.2 parts of antioxidant, 1 part of lubricant microspheres, 0.5 parts of mineral oil microspheres, and 2 parts of nucleating agent;

[0031] Wherein, described antioxidant is B215 antioxidant, and this antioxidant is made up of antioxidant 1010 and antioxidant 168, and the proportioning of antioxidant 1010 and antioxidant 168 is 4:6; Described Lubricant microspheres are micronano polyethylene wax solid microspheres prepared by electrospinning process, the mineral oil microspheres are prepared by white oil electrospinning process, and the glass microspheres and nucleating agent are obtained by ...

Embodiment 3

[0035] The artificial ice board is composed of the following materials by weight: 92 parts of ultra-high molecular weight polyethylene, 1.2 parts of coupling agent, 2.2 parts of lubricant, 14 parts of glass microspheres or talcum powder, 0.013 parts of fluorescent whitening agent OB, ultraviolet absorbing 0.75 parts of anti-oxidant, 0.17 parts of antioxidant, 0.7 parts of lubricant microspheres, 0.35 parts of mineral oil microspheres, 1.6 parts of nucleating agent;

[0036] Wherein, described antioxidant is B215 antioxidant, and this antioxidant is made up of antioxidant 1010 and antioxidant 168, and the proportioning of antioxidant 1010 and antioxidant 168 is 4:6; Described The lubricant microspheres are polyethylene wax solids prepared by an electrospinning process, the mineral oil microspheres are prepared by a white oil electrospinning process, and the glass microspheres and nucleating agent are inorganic foreign matter obtained by a spray drying method. The microcapsule s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com