Heat-resisting and anti-ageing rubber sealing gasket for plate-type heat exchanger

A plate heat exchanger and rubber sealing technology, which is applied to heat exchanger sealing devices, indirect heat exchangers, heat exchanger types, etc. The sealing function of the gasket is reduced, and the effect of excellent heat resistance, good sealing performance and good sealing performance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

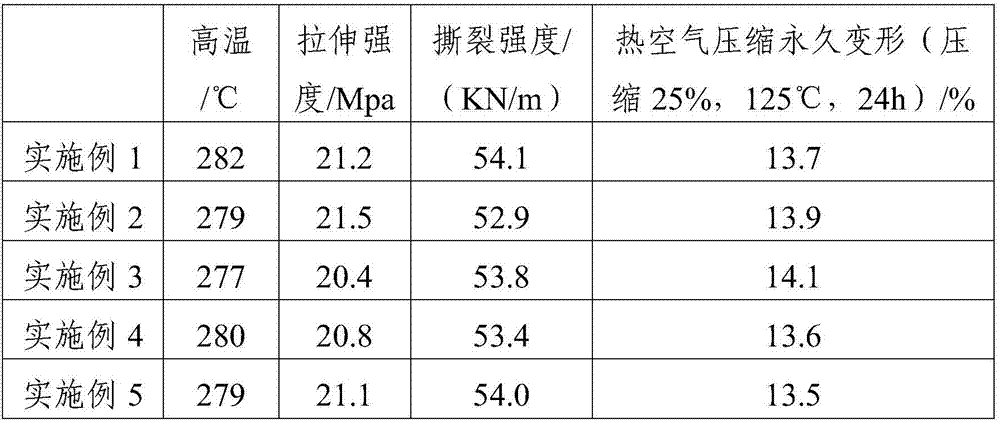

Examples

Embodiment 1

[0019] A heat-resistant and aging-resistant rubber sealing gasket for a plate heat exchanger, made of the following raw materials in parts by weight: 52 parts of EPDM rubber, 15 parts of methyl vinyl silicone rubber, 4 parts of ACR resin, and gas phase white carbon black 2 parts, 1 part of tetraacicular zinc oxide whisker, 1.2 parts of γ-aminopropyltriethoxysilane, 1.5-2 parts of magnesium hydroxide, 1.2 parts of magnesium stearate, rare earth oxide Ce 2 o 3 0.07 parts, 2 parts of dicumyl peroxide, 1.2 parts of accelerator, 0.6 parts of pentaerythritol tetrakis(3,5-di-tert-butyl-4-hydroxy)phenylpropionate.

[0020] The above-mentioned methyl vinyl silicone rubber has an average molecular weight of 500,000-700,000 and a vinyl content of 0.07-0.12 mol%.

[0021] The particle size of the above-mentioned fumed white carbon black is 40-60nm.

[0022] The above-mentioned accelerator is formed by mixing 2-mercaptobenzothiazole and thiuram at a mass ratio of 2:1.

Embodiment 2

[0024] A heat-resistant and aging-resistant rubber sealing gasket for a plate heat exchanger, which is made of the following raw materials in parts by weight: 45 parts of EPDM rubber, 10 parts of methyl vinyl silicone rubber, 5 parts of ACR resin, and gas phase white carbon black 3 parts, 0.5 parts of tetraacicular zinc oxide whiskers, 1.5 parts of γ-aminopropyltriethoxysilane, 1 part of magnesium hydroxide, 1 part of magnesium stearate, rare earth oxide La 2 o 3 0.08 parts, 1.5 parts of dicumyl peroxide, 1.2 parts of accelerator, 0.8 parts of 2,2'-methylenebis-(4-methyl-6-tert-butylphenol).

[0025] The above-mentioned methyl vinyl silicone rubber has an average molecular weight of 500,000-700,000, and a vinyl content of 0.07-0.12mol%;

[0026] The particle diameter of the above-mentioned fumed white carbon black is 50-70nm.

[0027] The above-mentioned accelerator is formed by mixing 2-mercaptobenzothiazole and thiuram at a mass ratio of 2:1.

Embodiment 3

[0029] A heat-resistant and aging-resistant rubber sealing gasket for a plate heat exchanger, made of the following raw materials in parts by weight: 65 parts of EPDM rubber, 15 parts of methyl vinyl silicone rubber, 7 parts of ACR resin, and gas phase white carbon black 2.5 parts, 1.5 parts of tetrapod zinc oxide whiskers, 0.8 parts of γ-aminopropyltriethoxysilane, 1.8 parts of magnesium hydroxide, 0.8 parts of magnesium stearate, rare earth oxide Y 2 o 3 0.05 parts, 2 parts of dicumyl peroxide, 1.5 parts of accelerator, 0.7 parts of pentaerythritol tetrakis(3,5-di-tert-butyl-4-hydroxy)phenylpropionate.

[0030] The above-mentioned methyl vinyl silicone rubber has an average molecular weight of 500,000-700,000, and a vinyl content of 0.07-0.12mol%;

[0031] The particle size of the above-mentioned fumed white carbon black is 40-60nm.

[0032] The above-mentioned accelerator is formed by mixing 2-mercaptobenzothiazole and thiuram at a mass ratio of 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com