Preparation method of bismuth titanate-based bismuth layered structure ferroelectric ceramic target

A technology of bismuth titanate-based bismuth and ferroelectric ceramics, which is applied in voltage variable capacitors, etc., can solve the problems of introducing impurities, cracking the surface layer, etc., and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a bismuth titanate-based bismuth layered structure ferroelectric ceramic target, the bismuth titanate-based ferroelectric ceramic dopant is La 2 o 3 and TaO 2 , the chemical formula is Bi 3.25 La 0.75 Ta 0.09 Ti 2.91 o 12 , weigh Bi according to the stoichiometric ratio 2 o 3 ,TiO 2 , La 2 o 3 and TaO 2 , with a purity of 99.99wt%, 99.99wt%, 99.99wt% and 99.5wt%, respectively, where Bi 2 o 3 Excess 3wt%, i.e. Bi 2 o 3 =34.316g, TiO 2 = 10.229g, La 2 o 3 =5.376g and TaO 2 = 0.880 g. Add the weighed raw material powder into an anhydrous ethanol medium, ball mill for 2 hours, put it into an oven for drying at 80°C, and then heat it at 800°C for 2 hours for pre-calcination. The powder obtained after pre-calcination is ball-milled for 1 hour for the second time, and after drying at 80°C, 2wt%, that is, 1.01g of polyvinyl alcohol binder is added, wherein the mass concentration of polyvinyl alcohol in the polyvinyl alcohol binder is ...

Embodiment 2

[0029] A method for preparing a bismuth titanate-based bismuth layered structure ferroelectric ceramic target, the bismuth titanate-based ferroelectric ceramic dopant is La 2 o 3 The chemical formula is Bi 3.25 La 0.75 Ti 3 o 12 , according to the chemical formula to weigh analytically pure Bi 2 o 3 ,TiO 2 and La 2 o 3 , with a purity of 99.99wt%, where Bi 2 o 3 Excess 2wt%, i.e. Bi 2 o 3 = 16.991g, TiO 2 =5.271g, La 2 o 3 = 2.688g. Add the weighed raw material powder into an anhydrous ethanol medium, ball mill for 2 hours, put it into an oven for drying at 80°C, and then heat it at 800°C for 2 hours for pre-calcination. The powder obtained after calcining is ball-milled for 1 hour for the second time, and after drying at 80°C, add 3wt%, that is, 0.75g of polyvinyl alcohol binder, wherein the polyvinyl alcohol binder The mass concentration of polyvinyl alcohol in it is 10%, and it is pressed under 100MPa pressure. The obtained ceramic green body was heat-pres...

Embodiment 3

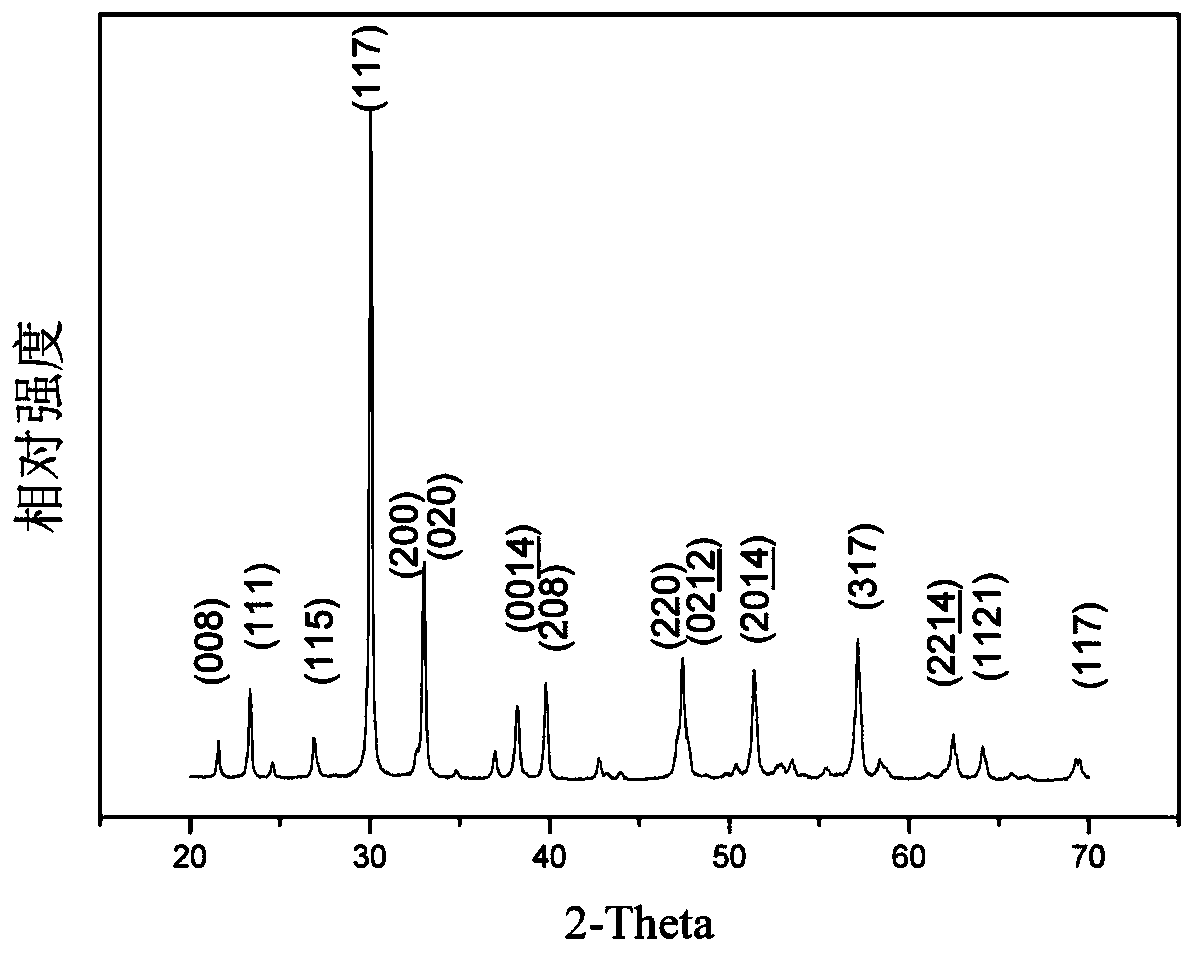

[0031] A method for preparing a bismuth titanate-based bismuth layered structure ferroelectric ceramic target, the chemical formula of the bismuth titanate-based ferroelectric ceramic is Bi 4 Ti 3 o 12 , according to the chemical formula to weigh Bi 2 o 3 and TiO 2 , with a purity of 99.99wt%, where Bi 2 o 3 Excess 4wt% is Bi 2 o 3 =42.648g, TiO 2 =10.543g, all the other conditions are with embodiment 1. Finally, a bismuth titanate-based bismuth layered structure ferroelectric ceramic target is obtained. The XRD test of the target shows that the ceramic is a pure bismuth layered structure, and no impurity phase appears. When the target is used in the process of preparing the ferroelectric thin film by radio frequency magnetron sputtering, no cracking occurs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com