Preparation method and application of phase change material for energy-saving building

A phase change material and construction technology, applied in the field of construction materials, can solve the problems of large supercooling, small thermal conductivity, large volume change, etc., and achieve the effect of improving thermal stability and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

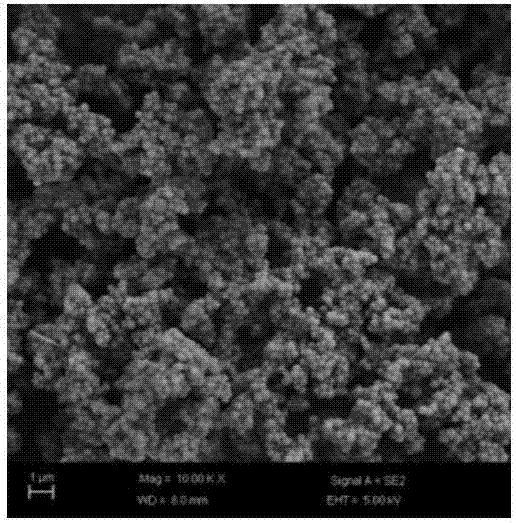

Image

Examples

Embodiment 1

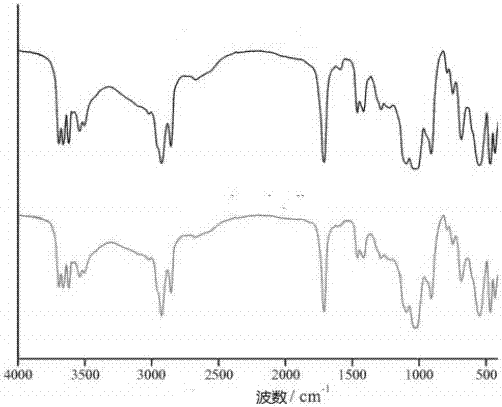

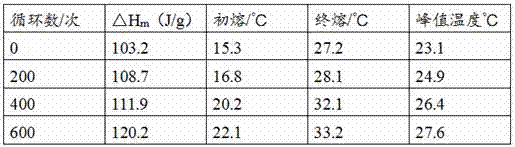

[0025] 1. Preparation of phase change materials for energy-saving buildings

[0026] Include the following steps:

[0027] 1) 300 g myristic acid, 200 g capric acid, 2 kg 2-hydroxyethyl acrylate, 3.3 kg methyl methacrylate and 100 g α-[tris(phenylmethyl)phenyl]-ω-hydroxypoly(oxy Base-1,2-ethylene) was added to 50L of purified water, and then sheared at 60°C with a 100L high-shear dispersing emulsifier for 3 hours to obtain an emulsion;

[0028] 2) Add 6g of dibenzoyl peroxide to the emulsion obtained in step 1), then raise the temperature to 80°C, and add dropwise an aqueous solution of ferrous chloride with a concentration of 0.2mol / L (containing 2.1g of ferrous chloride) to obtain solution to be polymerized;

[0029] 3) Add 6.3kg α,ω-dimethacrylate-based polyethylene glycol in batches to the solution to be polymerized, then add 0.9kg chitosan at a time and stir at high speed for 20min, and finally add 1.2kg 12%wt poly Formaldehyde aqueous solution, after the dropwise addi...

Embodiment 2

[0040] Prepare phase-change mortar for energy-saving buildings. The specific preparation method includes the following steps: 100 parts by weight of cement, 20 parts of phase-change material (prepared in Example 1), 40 parts by weight of expanded perlite, 8 parts of polycarboxylate Acid-based water reducer, 300 parts of water, 15 parts of latex powder ethylene-vinyl acetate copolymer, 5 parts of aliphatic air-entraining agent, 11 parts by weight of polypropylene fiber, 22 parts by weight of a mixture of heavy calcium powder and light calcium powder ( 11 parts of heavy calcium powder, 11 parts of light calcium powder) and stir well.

[0041] The physical and mechanical properties of the prepared phase change mortar were tested according to the testing method in GB / T 20473-2006, and the results are shown in Table 2:

[0042] Table 2 Test results of physical and mechanical properties of phase change mortar

[0043]

[0044] The above results show that the phase change mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com