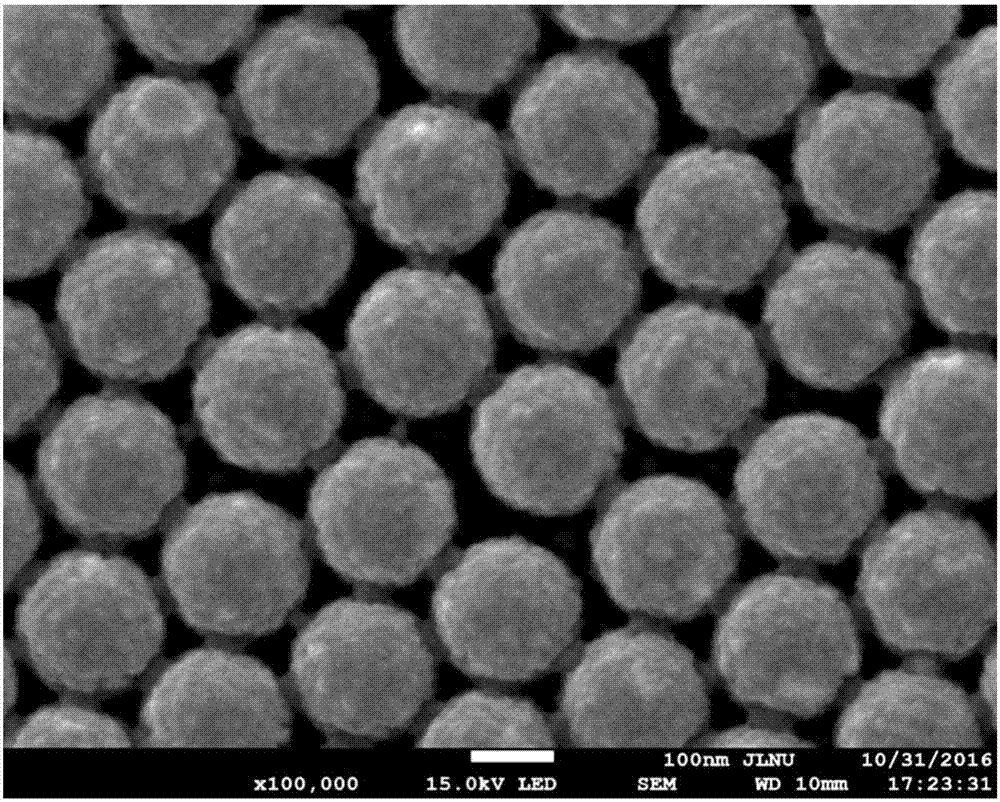

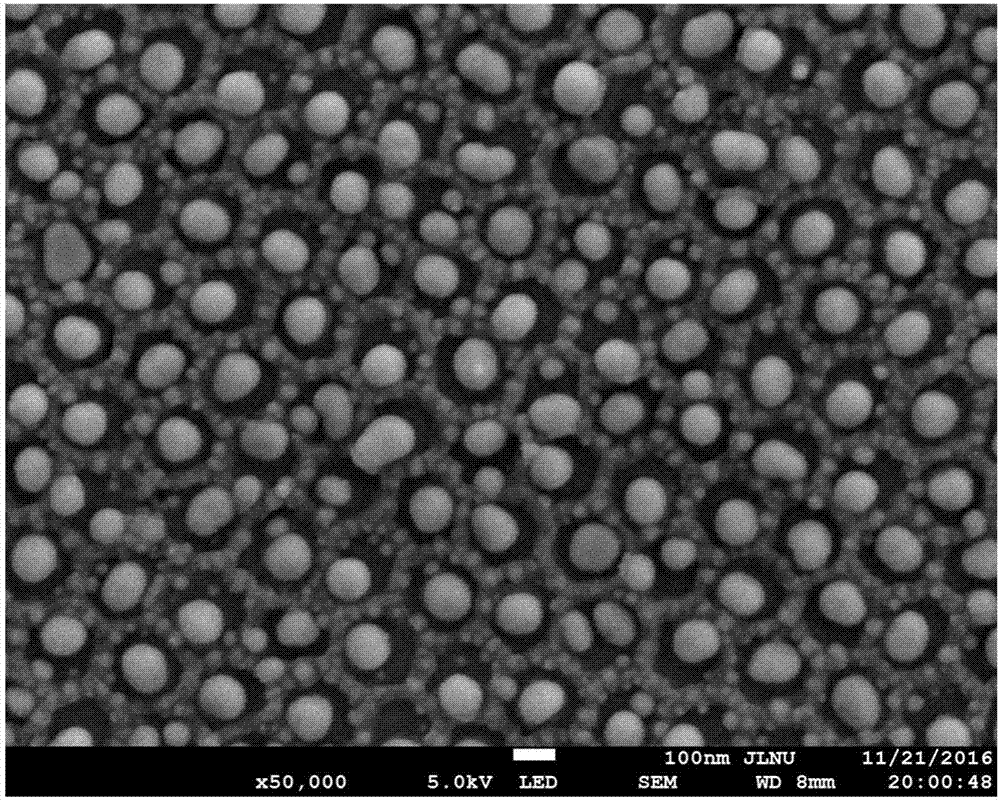

Honeycomb TiO2-Ag nanocomposite and preparation method thereof

A nanocomposite, honeycomb-like technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as difficulty in synthesizing non-silicon-based materials, and achieve highly ordered structure and simple process. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of two-dimensional ordered polystyrene colloidal arrays

[0024] A single-layer two-dimensional ordered colloidal ball template was prepared by self-assembly technology. The specific steps were: put the silicon wafer substrate in a mixed solution containing ammonia, hydrogen peroxide and water (volume ratio: 1:2:6) for 300 °C for 5-10 minutes, and then ultrasonically cleaned with deionized water and ethanol solution for 2-3 times. Soak it in 2% sodium lauryl sulfate solution for 24 hours to obtain a hydrophilic substrate surface. Take polystyrene solution and ethanol solution with a volume ratio of 1:1 and mix them, ultrasonically oscillate for 5s, then take an appropriate amount of the mixed solution and drop it on the silicon wafer substrate after hydrophilic treatment. Immerse in a container with a concentration of 12-15mmol / L NaCl saline solution. Under the action of the surface tension of the brine, the mixed solution oscillates and diffuses with th...

Embodiment 2

[0030] 1. Preparation of two-dimensional ordered polystyrene colloidal arrays

[0031] A single-layer two-dimensional ordered colloidal ball template was prepared by self-assembly technology. The specific steps were: put the silicon wafer substrate in a mixed solution containing ammonia, hydrogen peroxide and water (volume ratio: 1:2:6) for 300 °C for 5-10 minutes, and then ultrasonically cleaned with deionized water and ethanol solution for 2-3 times. Soak it in 2% sodium lauryl sulfate solution for 24 hours to obtain a hydrophilic substrate surface. Take polystyrene solution and ethanol solution with a volume ratio of 1:1 and mix them, ultrasonically oscillate for 5s, then take an appropriate amount of the mixed solution and drop it on the silicon wafer substrate after hydrophilic treatment. Immerse in a container filled with a NaCl solution with a concentration of 12-15mmol / L. Under the action of the surface tension of the brine, the mixed solution oscillates and diffuses ...

Embodiment 3

[0037] 1. Preparation of two-dimensional ordered polystyrene colloidal arrays

[0038]A single-layer two-dimensional ordered colloidal ball template was prepared by self-assembly technology. The specific steps were: put the silicon wafer substrate in a mixed solution containing ammonia, hydrogen peroxide and water (volume ratio: 1:2:6) for 300 °C for 5-10 minutes, and then ultrasonically cleaned with deionized water and ethanol solution for 2-3 times. Soak it in 2% sodium lauryl sulfate solution for 24 hours to obtain a hydrophilic substrate surface. Take polystyrene solution and ethanol solution with a volume ratio of 1:1 and mix them, ultrasonically oscillate for 5s, then take an appropriate amount of the mixed solution and drop it on the silicon wafer substrate after hydrophilic treatment. Immerse in a container with a concentration of 12-15mmol / L NaCl saline solution. Under the action of the surface tension of the brine, the mixed solution oscillates and diffuses with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com