Polyurethane-urea elastomeric fiber with low-temperature workability

A technology of polyurethane urea and elastic yarn, which is applied in the manufacture of one-component polyurethane rayon, one-component polyurea rayon, rayon, etc., and can solve the problems of unfavorable spinning operation, decrease of modulus and elastic recovery rate, Problems such as poor uniformity of raw silk can prevent heat embrittlement, improve touch, and prevent curling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

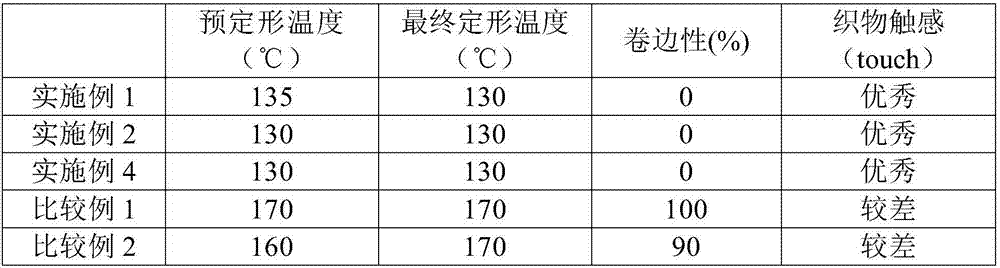

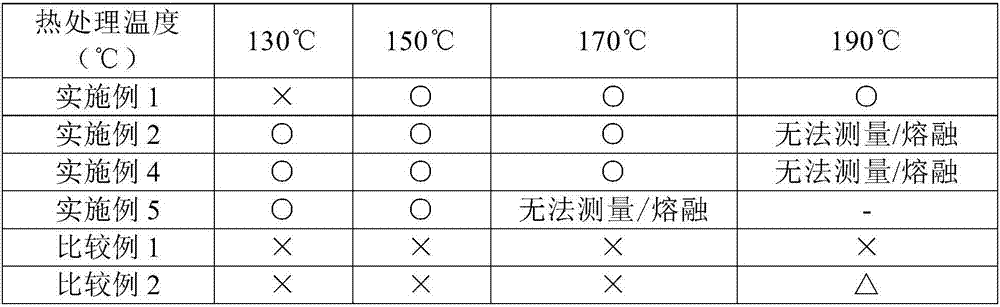

Examples

Embodiment 1

[0060] A first polymer was prepared by mixing polytetramethylene ether glycol with a molecular weight level of 1800 and 4,4'-diphenylmethane diisocyanate at a capping ratio (CR) of 1.61. Ethylenediamine was used as the first chain extender, ethylene glycol was used as the second chain extender, and diethylamine was used as the chain terminator. The ratio of the first chain extender and the second chain extender is set to 7:3, and the total concentration of the mixed solution obtained by mixing the first chain extender, the second chain extender and the chain terminator used is adjusted was 7 mol%, and dimethylacetamide was used as a solvent. That is, in a nitrogen stream, 35.2 g of polytetramethylene ether glycol with a molecular weight of 1800 and 7.8 g of methylene diisocyanate were stirred at 90° C. to react for 180 minutes, thereby preparing polyurethane urea with isocyanate at both ends prepolymer.

[0061] After cooling the above prepolymer to room temperature, 55.3 g ...

Embodiment 2

[0065] Except that 1,3-propylenediamine as the first chain extender and ethylene glycol as the second chain extender were used at a ratio of 7:3, polyurethane urea elastic yarn was produced in the same manner as in Example 1.

Embodiment 3

[0067] Except that the capping ratio (CR) of polytetramethylene ether glycol with a molecular weight level of 1800 and 4,4'-diphenylmethane diisocyanate was changed to 1.7, polyurethane urea elastic was produced in the same way as in Example 2 Silk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com