Deodorization device for tail gas of garbage aerobic fermentation equipment

An aerobic fermentation and tail gas technology, which is applied in the direction of gas treatment, separation methods, and dispersed particle separation, can solve the problems of increasing energy consumption of garbage rapid fermentation equipment, limited deodorization effect, and waste of heat, so as to improve equipment processing efficiency, Easy operation and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention.

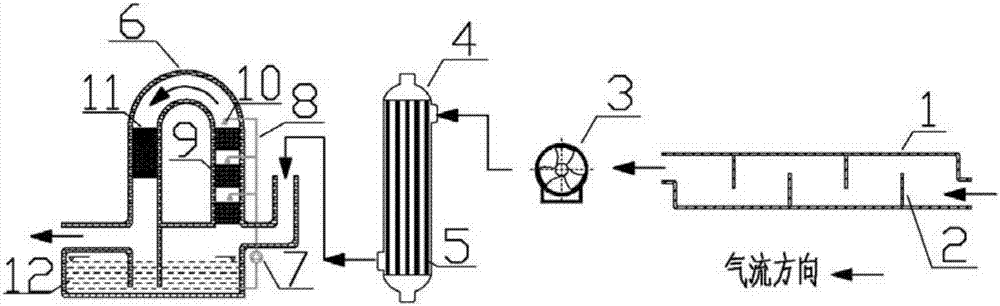

[0016] Such as figure 1 As shown, a deodorization device for the exhaust gas of aerobic fermentation equipment for food waste includes the following main components: inertial dust collector 1, dust removal baffle 2, exhaust fan 3, tubular heat exchanger 4, stainless steel heat exchanger Pipe 5, U-shaped spray deodorizer 6, lift pump 7, drain pipe 8, packing layer 9, atomizing spray head 10, stainless steel demister 11, and chemical collection tank 12. The rated processing capacity of the food waste aerobic fermentation equipment is 2 tons / day, the fermentation temperature is lower than 60°C, the stirring cycle is 20 minutes / hour, the aeration cycle is 25 minutes / hour, and the ventilation volume is 50-80 cubic meters / hour hours, the amount of waste gas generated is about 2000 cubic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com