Porous silicon dioxide-coated titanium dioxide nanopowder photocatalytic material and preparation method thereof

A technology of porous silica and photocatalytic materials, which is applied in the field of photocatalytic materials, can solve the problems of non-size selectivity, irregular organic membrane, and unstable structure, and achieve excellent degradation effect, uniform mesopore size, good Barrier degradation and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the nano-powder photocatalyst of porous silicon dioxide coating titania, comprises the steps:

[0044] Measure 60mL of deionized water and 15mL of ethanol in a three-necked flask, add 4g of nano-titanium dioxide (P25) and 0.4g of sodium dodecylsulfonate to stir and ultrasonically disperse to obtain a uniform dispersion, add ammonia water to the pH of the dispersion while stirring to 9, slowly add 0.5 mL of tetraethyl silicate. Placed at 60°C for 2 hours, filtered and washed to obtain a white powder, and calcined at 550°C for 2 hours to obtain a nano-powder photocatalytic material of porous silicon dioxide coated titanium dioxide. The particle size of the obtained powder photocatalytic material is 50-70nm, the particle size distribution is narrow, and the thickness of the silicon dioxide coating layer is 5-15nm.

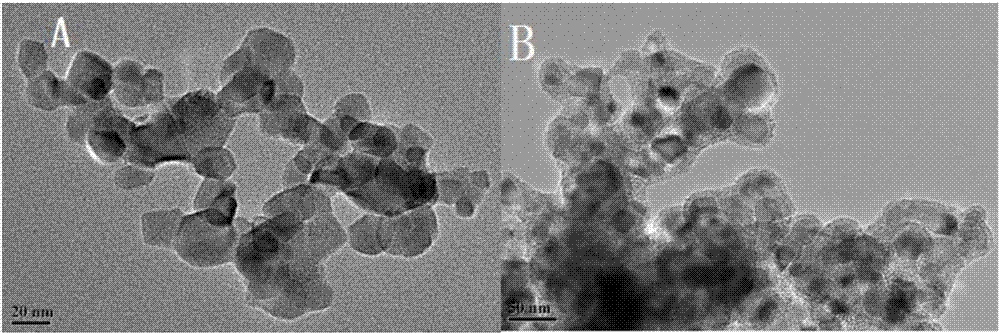

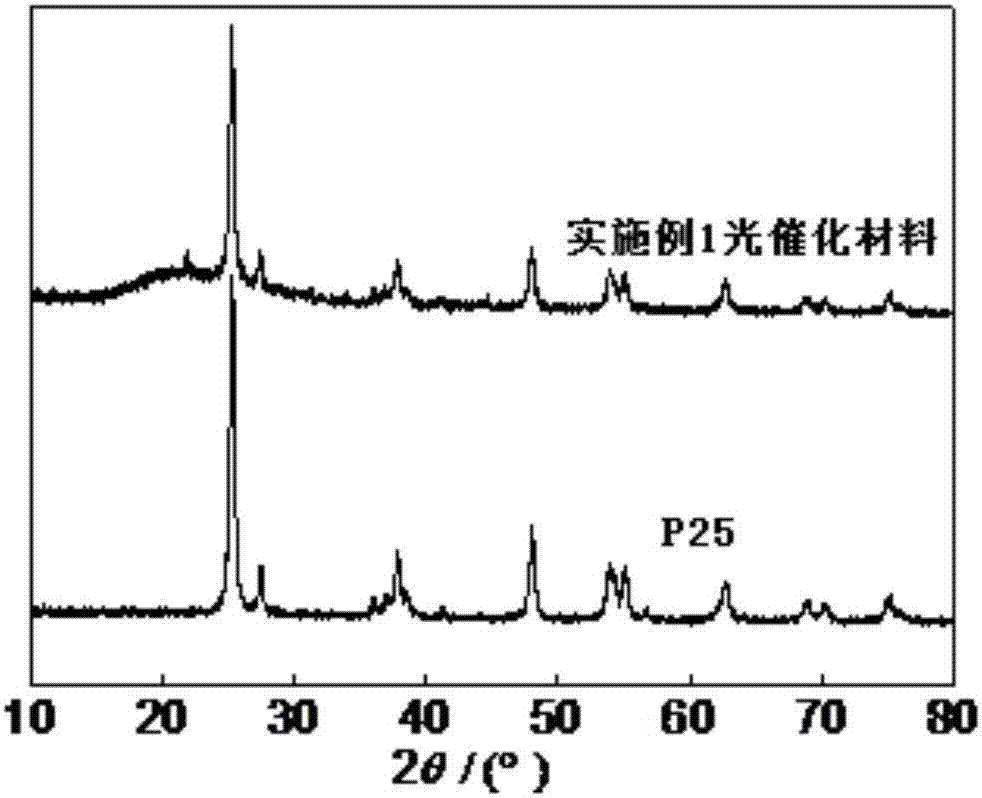

[0045] figure 1 Shows the raw material P25 (A) and the obtained photocatalytic material TiO 2 @SiO 2 TEM image of the core-shell ...

Embodiment 2

[0049] The preparation method of the nano-powder photocatalyst of porous silicon dioxide coating titania, comprises the steps:

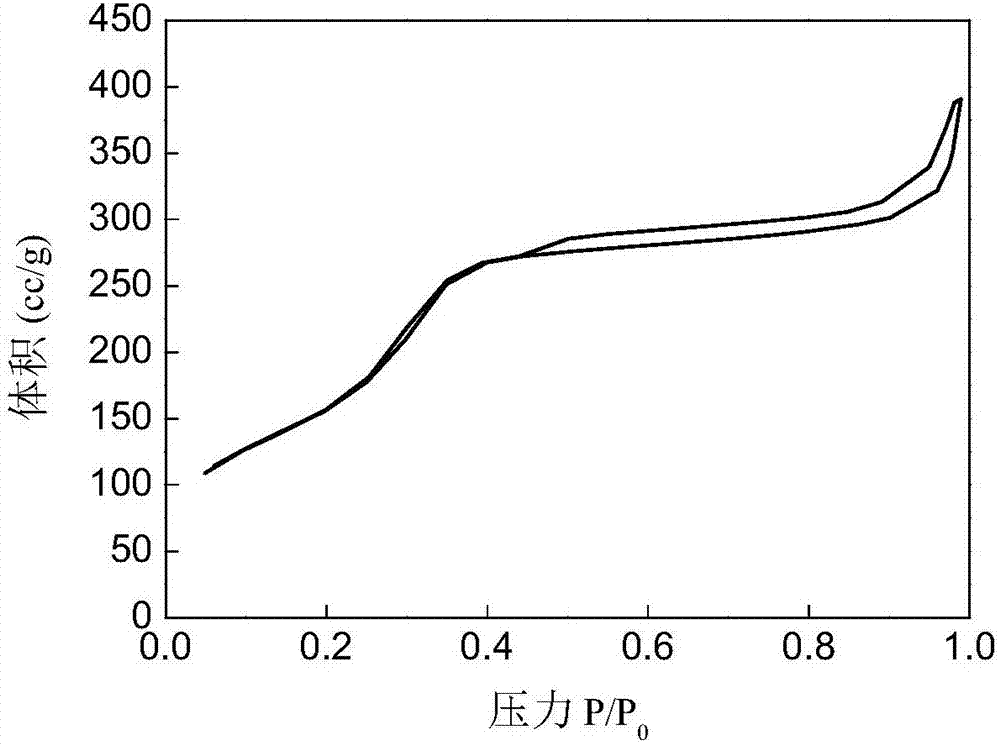

[0050] Measure 60mL of deionized water and 15mL of ethanol in a three-necked flask, add 4g of nano-titanium dioxide (PC500) and 0.4g of cetyltrimethylammonium bromide, stir and ultrasonically disperse to obtain a uniform dispersion, add ammonia water to The pH of the dispersion was 10, and 0.5 mL of tetraethyl silicate was slowly added. Placed at 60°C for 2 hours, filtered and washed to obtain a white powder, calcined at 550°C for 2 hours to remove the surfactant, and obtained a nano-powder photocatalytic material of porous silicon dioxide coated titanium dioxide. The particle size of the obtained powder photocatalytic material is 90-100nm, and the specific surface area is 512m 2 / g, the thickness of the silica coating layer is 6-9 nm, and the mesopore diameter is 2-3 nm.

Embodiment 3

[0052] The preparation method of the nano-powder photocatalyst of porous silicon dioxide coating titania, comprises the steps:

[0053] Measure 60mL of deionized water and 15mL of ethanol in a three-necked flask, add 4g of nano-titanium dioxide (ST-31) and 0.4g of polyvinylpyrrolidone to stir and ultrasonically disperse to obtain a uniform dispersion, add sodium hydroxide to the pH of the dispersion while stirring to 10, slowly add 0.5 mL of tetraethyl silicate. Placed at 60°C for 2 hours, filtered and washed to obtain a white powder, and calcined at 550°C for 2 hours to obtain a nano-powder photocatalytic material of porous silicon dioxide coated titanium dioxide. The obtained powder photocatalytic material has a particle size of 70-100nm and a specific surface area of 508m 2 / g, the thickness of the silica coating layer is 7-10 nm, and the mesopore diameter is 2-3 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com