Sequencing-batch simultaneous saccharified photosynthetic biological hydrogen production reactor and hydrogen production operation method thereof

A technology of hydrogen production reactor and synchronous saccharification, which is applied in photobioreactor, enzyme production/bioreactor, bioreactor/fermenter combination, etc. problems such as low energy conversion efficiency, to achieve the effect of reducing the number, releasing the inhibition effect, and reducing the reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

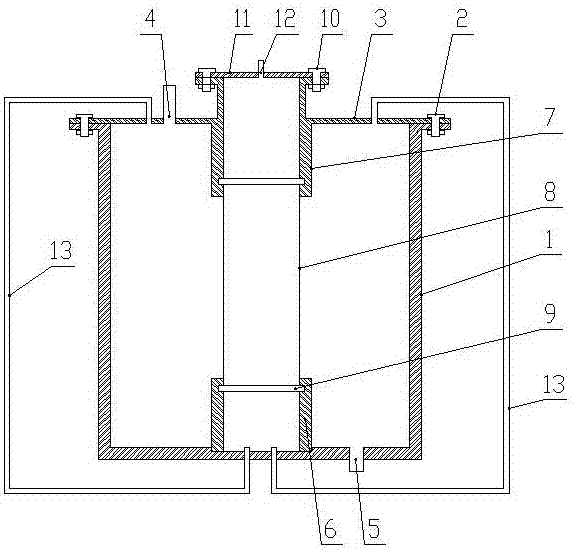

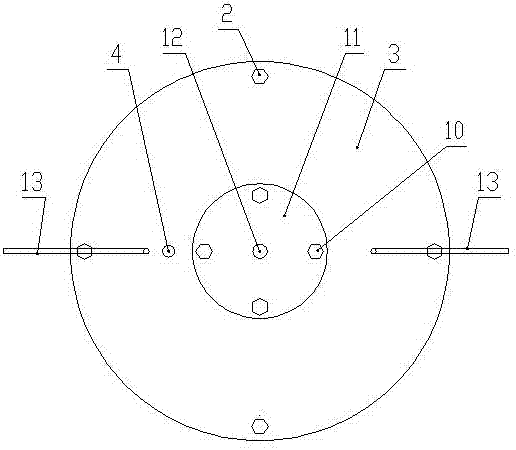

[0022] Such as figure 1 and figure 2 As shown, the sequencing batch synchronous saccharification photosynthetic biological hydrogen production reactor of the present invention includes a photosynthetic hydrogen production unit and an enzymatic hydrolysis reaction unit arranged inside the photosynthetic hydrogen production unit.

[0023] The photosynthetic hydrogen production unit comprises a transparent container 1 with an open top and a cylindrical shape, the top of the transparent container 1 is provided with a first sealing cover 3 through a first mounting bolt 2, and a feeding hole 4 is provided on the first sealing cover 3, A discharge hole 5 is arranged at the bottom of the transparent container 1 .

[0024] The enzymolysis reaction unit comprises a lower cylinder body 6, an upper cylinder body 7 and a permeable membrane cylinder body 8 whose center lines coincide and are arranged vertically. Through and fixedly connected to the first sealing cover 3, the upper end an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com