Preparation method of high thermal conductivity encapsulated phase change material with uniform particle size

A technology of phase-change microcapsules and high thermal conductivity, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of poor heat transfer performance and large particle size distribution of phase-change microcapsules, and achieve improved storage capacity. Energy efficiency, improved heat transfer coefficient, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

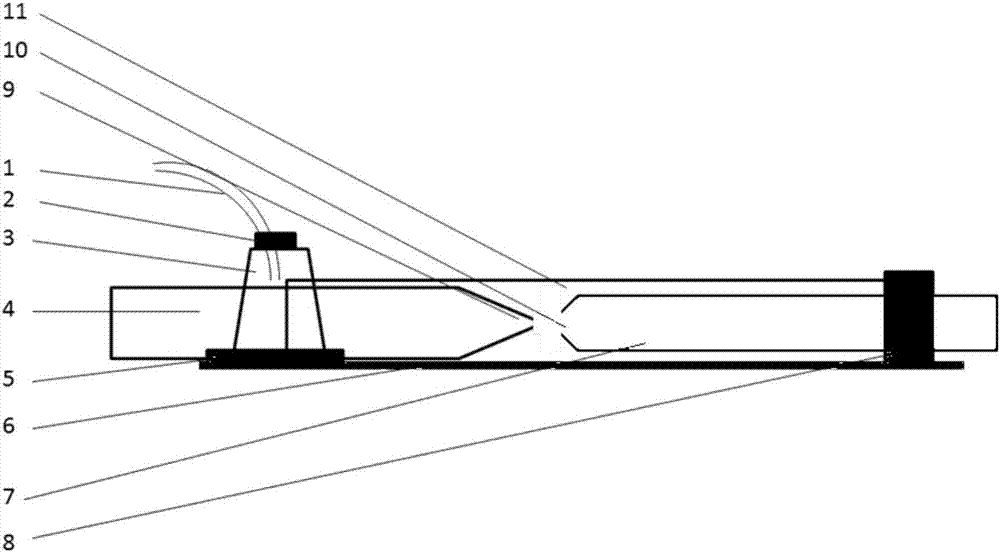

Method used

Image

Examples

Embodiment 1

[0047] (1) Take 4ml of heptadecane mixed solution with a 5ml syringe, take 15ml of aqueous solution with a 20ml syringe, fix the syringe on the precision syringe pump, and connect it with the sharp-nosed round capillary and cone core of the microfluidic chip through the Teflon catheter. The centrifuge tube is connected to the catheter.

[0048] (2) Adjust the flow rates of the continuous phase and the dispersed phase of the coaxial flow microchip to 10 μml min, respectively -1 and 20μml·min -1 . The continuous phase is introduced first, followed by the dispersed phase.

[0049] (3) Collect the microemulsion flowing out from the outlet section of the microchip, and place it in an incubator at 45° C. for 10 hours for curing reaction of the capsule wall.

[0050] (4) Filtrate the solidified suspension, wash it several times with deionized water, and freeze-dry to obtain phase-change microcapsules doped with nano-titanium dioxide with a particle size of 100 μm and a polydispers...

Embodiment 2

[0052] Step (1), (3) are the same as implementation example 1.

[0053] In step (2), the flow rates of the continuous phase and the dispersed phase of the coaxial flow microchip were 15 μml min -1 and 20μml·min -1 . The continuous phase is introduced first, followed by the dispersed phase.

[0054] Step (4) is the same as that of Example 1, but the particle size is 150 μm, and the phase-change microcapsules doped with nano-titanium dioxide with a polydispersity of less than 3% are obtained.

Embodiment 3

[0056] Step (1) Take 2ml of the mixed solution of paraffin and titanium dioxide TDI with a 5ml syringe, take 15ml of the mixed solution of water, sodium dodecylbenzenesulfonate and TEPA with a 20ml syringe, and connect the interfaces of the dispersed phase and the continuous phase respectively.

[0057] Steps (2), (3), (4) are the same as implementation example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com