Brewing method for high free-state amino acid table vinegar

A free amino acid and vinegar technology, applied in the direction of microorganism-based methods, vinegar preparation, biochemical equipment and methods, etc., can solve the problems of high protein content, low amino acid nitrogen content, low protein utilization rate of vinegar grains, etc. Achieve the effect of improving utilization rate and reducing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

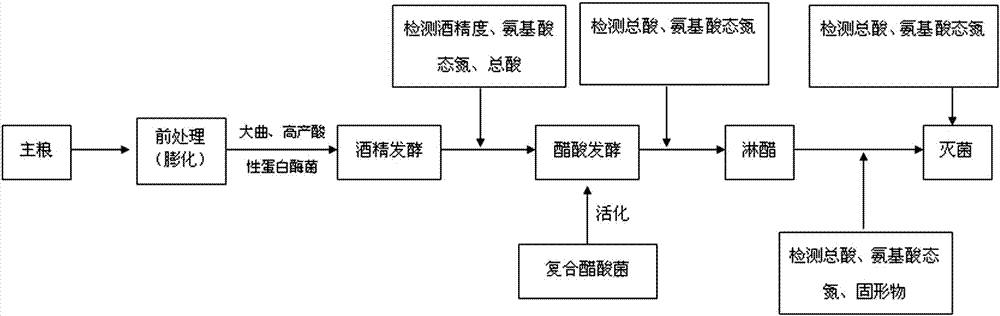

Method used

Image

Examples

experiment example 1

[0026] Experimental example 1: Preparation of pure microbial solid culture:

[0027] Acid protease producing strain Aspergillus niger ( Aspergillus niger ) And the neutral protease producing bacteria Bacillus subtilis ( Bacillus subtilis ) The medium raw materials and weight ratio of the solid bacteria preparations are: bran 55%, soybean meal 45%, adding 70% of the total raw material water, natural pH, 121 ℃ sterilization for 20-30 minutes; under aseptic conditions in the above The acid protease-producing bacteria Aspergillus niger ( Aspergillus niger ) And the neutral protease producing bacteria Bacillus subtilis ( Bacillus subtilis ) Seed liquid, the inoculum amount is 5%, Aspergillus niger is statically cultured at 30°C for 48h, Bacillus subtilis is statically cultured at 35°C for 48h, and the bacterial count is measured after 48h. The results are shown in Table 1.

[0028] Table 1: Effective number of viable bacteria in culture

[0029]

experiment example 2

[0030] Experimental Example 2: Detection of protease activity: The protease activity was measured by the Folin method. The specific implementation scheme is as follows:

[0031] (1) Preparation of enzyme solution: 10g of the solid inoculum of Aspergillus niger and Bacillus subtilis prepared in Experimental Example 1 were dried at 40°C, pulverized and sampled, added with deionized water, and extracted in a 40°C water bath for 30 min. The extract was filtered with filter paper, and the filtrate was taken to a constant volume of 10 ml for protease activity determination.

[0032] (2) Determination of protease activity: According to the Folin method (Zhang Shuzheng. Enzyme Preparation Industry [M]. Science Press, 1984.), the reaction substrate is 2% casein solution. The test results are shown in Table 2.

[0033] Table 2: Test results of culture protease activity

[0034]

[0035] Note: Calculation of protease activity: The amount of enzyme (g) that produces 1 mg of tyrosine in 1 min is ...

experiment example 3

[0036] Experimental example 3: Optimization experiment of the ratio of Aspergillus niger and Bacillus subtilis in the mixed solid bacterial preparation:

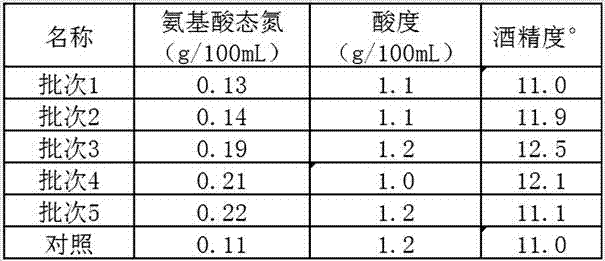

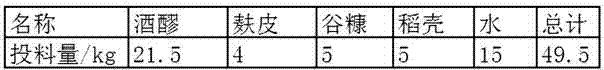

[0037] The raw materials used in alcohol fermentation and the ratio are: sorghum 10kg, Daqu 6kg, water 30kg, and 5 experimental groups are set up. The formula of the mixed bacteria preparation in each experimental group is: a mixture of acid protease-producing Aspergillus niger and neutral protease-producing Bacillus subtilis The proportions were inoculated according to 8:2; 7:3; 6:4; 5:5; 4:6. The inoculation amount of mixed bacteria preparation was 2kg (20% of the weight of sorghum). The control was Aspergillus niger and Bacillus subtilis 0, add 2kg of bran, the specific experimental formula and dosage are shown in Table 3.

[0038] Before fermentation, the sorghum was puffed, and then blended according to the alcohol fermentation formula shown in Table 3. The rakes were raked in the morning and evening, and the temperature was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com