Preparation method of transition metal phosphide nano hollow spheres

A transition metal, phosphide technology, applied in the direction of phosphide, can solve the problems of many by-products, expensive raw materials, unsuitable operation, etc., and achieve the effects of large specific surface area, mild reaction conditions and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

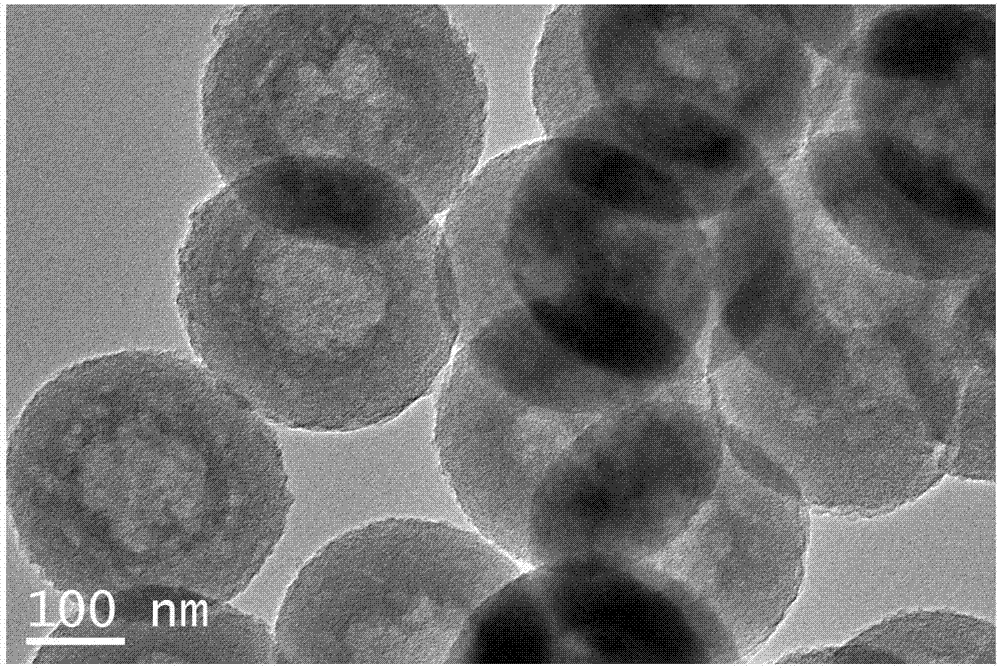

Embodiment 1

[0022] (1) Weigh 20mg of cobalt oxide nanospheres and disperse them in 50mL of ethylene glycol solvent;

[0023] (2) Add 100 mg of sodium hypophosphite to the dispersion obtained in step (1), and react in an oil bath at 100° C. for 12 hours;

[0024] (3) The product obtained in step (2) is washed with water and ethanol by suction filtration for several times, and vacuum-dried at 60° C.;

[0025] (4) Etching the product obtained in step (3) for 12 hours at 20°C in a 1mol / L hydrochloric acid solution;

[0026] (5) The product obtained in step (4) is centrifuged, washed with water, and vacuum-dried at 60° C. to obtain transition metal cobalt phosphide hollow spheres.

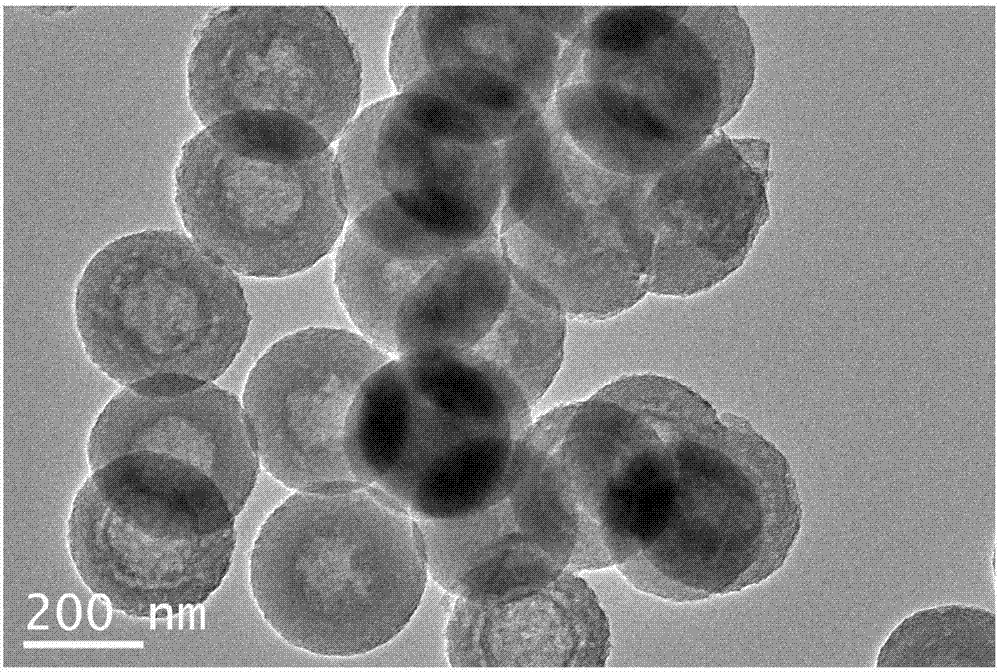

Embodiment 2

[0028] (1) Weigh 40mg of nickel oxide nanospheres and disperse them in 50mL of ethylene glycol solvent;

[0029] (2) Add 100 mg of sodium hypophosphite to the dispersion obtained in step (1), and react in an oil bath at 100° C. for 12 hours;

[0030] (3) The product obtained in step (2) is washed with water and ethanol by suction filtration for several times, and vacuum-dried at 60° C.;

[0031] (4) Etching the product obtained in step (3) for 12 hours at 40°C in a 1mol / L sulfuric acid solution;

[0032] (5) The product obtained in step (4) is centrifuged, washed with water, and vacuum-dried at 60° C. to obtain transition metal nickel phosphide hollow spheres.

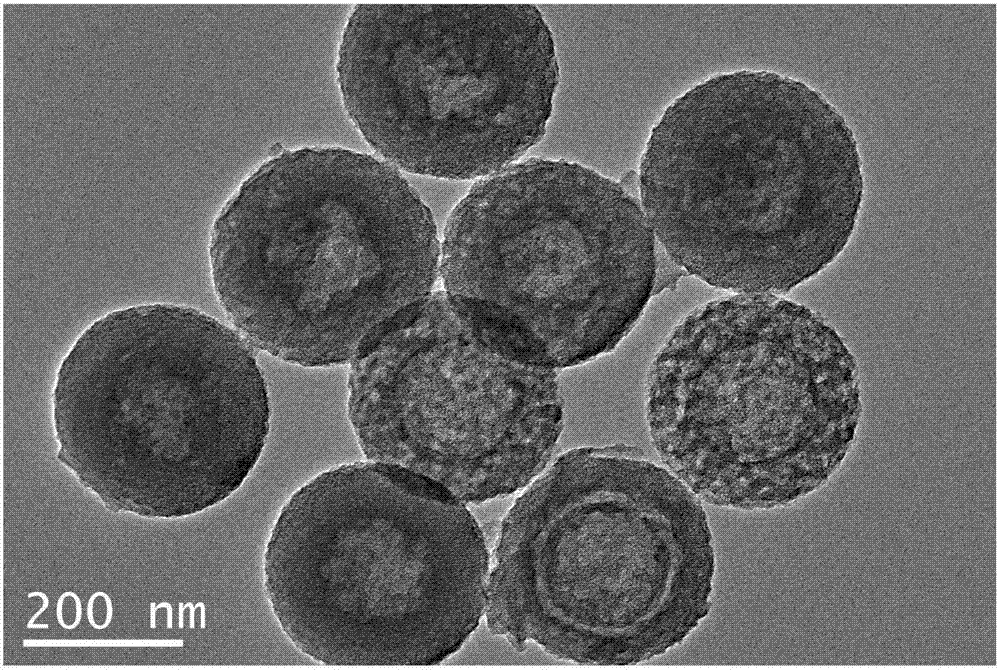

Embodiment 3

[0034] (1) Weigh 60mg of manganese oxide nanospheres and disperse them in 50mL of ethylene glycol solvent;

[0035] (2) Add 100 mg of sodium hypophosphite to the dispersion obtained in step (1), and react in an oil bath at 100° C. for 12 hours;

[0036] (3) The product obtained in step (2) is washed with water and ethanol by suction filtration for several times, and vacuum-dried at 60° C.;

[0037] (4) Etching the product obtained in step (3) for 12 hours at 20°C in a 1mol / L hydrochloric acid solution;

[0038] (5) The product obtained in step (4) is centrifuged, washed with water, and dried under vacuum at 60° C. to obtain transition metal manganese phosphide hollow spheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com