Method for refining salvianolic acid A and protocatechuic aldehyde simultaneously

A technology of protocatechualdehyde and salvianolic acid, which is applied in the field of medicine, can solve the problems of easy emulsification, high solubility in water, and low selectivity of salvianolic acid A extractant, and achieve solvent recovery and regeneration with high interfacial tension , the effect of easy phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

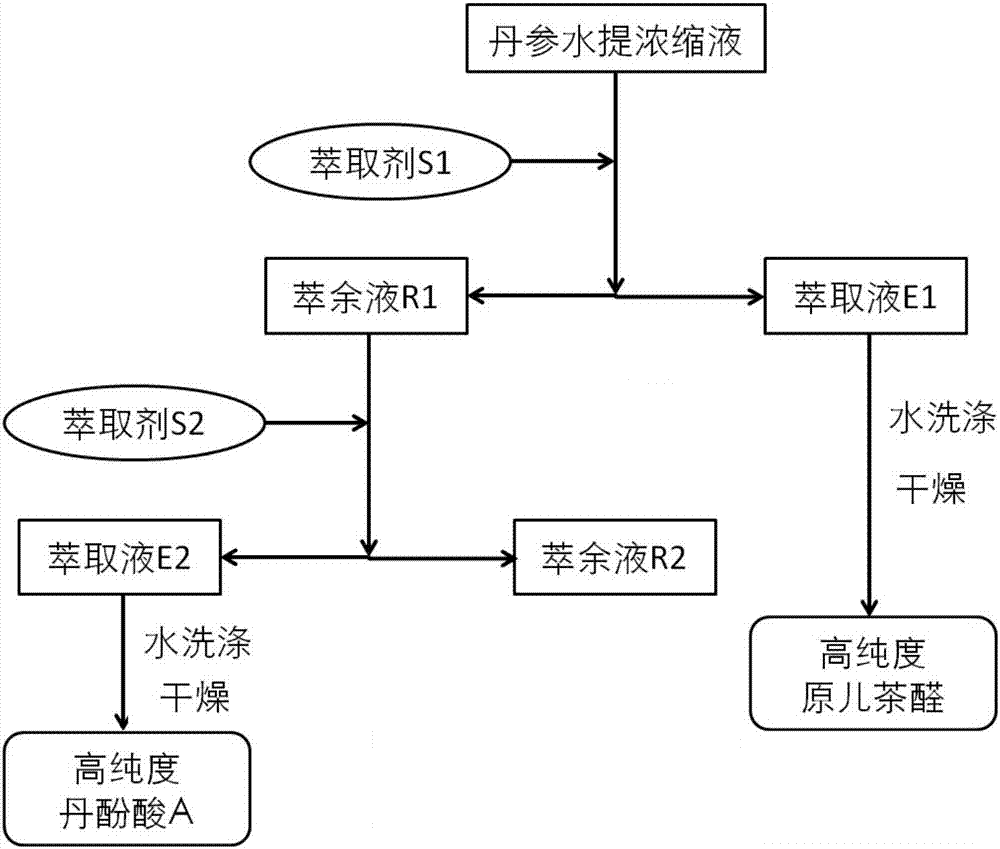

[0035] Take 1Kg of Salvia miltiorrhiza, add 6Kg of water, decoct for 120min, then filter to get the filtrate. Add 6Kg of water, decoct for 120min and then filter to get the filtrate. The two filtrates were combined and then concentrated under reduced pressure until the concentrated solution was 1.10 g / mL for use. Take 800g of ethyl acetate and 200g of n-heptane, and mix them to make extractant S1 for later use. Take 999g of ethyl acetate and 1g of n-heptane, and mix them to make extractant S2 for later use.

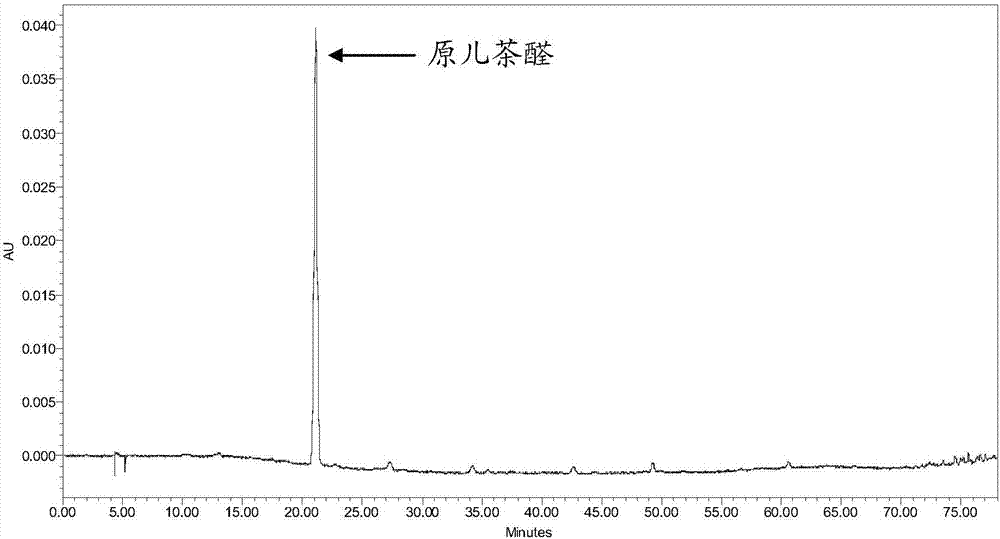

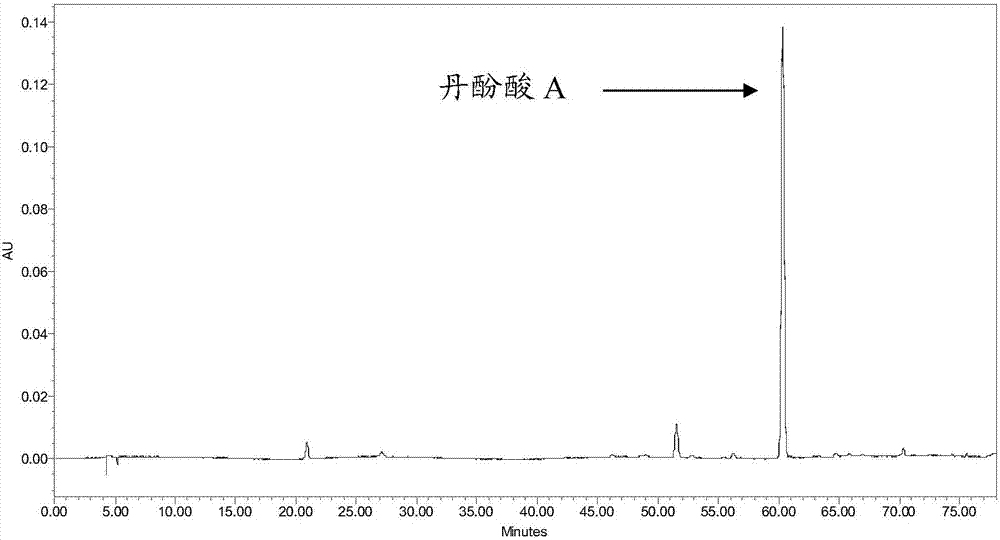

[0036] Take 200g of extractant S1, extract 100g of Danshen water-extracted concentrate in a separatory funnel, shake fully and let stand to separate phases. After phase separation, extract E1 and raffinate R1 are obtained. Wash the extract E1 twice with 700 mL of water in a separatory funnel to obtain an organic phase O1 after washing. The organic phase O1 was vacuum-dried at low temperature to obtain protocatechualdehyde with a purity of 90.2% and a recovery rate of ...

Embodiment 2

[0039] Take 1Kg of Salvia miltiorrhiza, add 6Kg of water, decoct for 120min, then filter to get the filtrate. Add 6Kg of water, decoct for 120min and then filter to get the filtrate. The two filtrates were combined and then concentrated under reduced pressure until the concentrated solution was 1.08 g / mL for use. Take 200g of n-butanol and 800g of n-pentane, and mix them to make extraction agent S1 for later use. Take 500g of n-butanol and 500g of n-pentane, and mix them to make extractant S2 for later use.

[0040]Take 200g of extractant S1, extract 100g of Danshen water-extracted concentrate in a separatory funnel, shake fully and let stand to separate phases. After phase separation, extract E1 and raffinate R1 are obtained. Wash the extract E1 twice with 600 mL of water in a separatory funnel to obtain an organic phase O1 after washing. The organic phase O1 was vacuum-dried at low temperature to obtain protocatechualdehyde with a purity of 93.6% and a recovery rate of 7...

Embodiment 3

[0043] Take 1Kg of Salvia miltiorrhiza, add 6Kg of water, decoct for 120min, then filter to get the filtrate. Add 6Kg of water, decoct for 120min and then filter to get the filtrate. The two filtrates were combined and then concentrated under reduced pressure until the concentrated solution was 1.15 g / mL for use. Take 300g of methyl isobutyl ketone and 700g of isooctane, and mix them to prepare extractant S1 for use. Take 600g of methyl isobutyl ketone and 400g of isooctane, and mix them to make extractant S2 for later use.

[0044] Take 200g of extractant S1, extract 100g of concentrated salvia miltiorrhiza in a separatory funnel, shake it well, let it stand for phase separation, repeat the extraction three times, and combine the extracts to obtain extract E1 and raffinate R1. Wash the extract E1 twice with 1500 mL of water in a separatory funnel to obtain an organic phase O1 after washing. The organic phase O1 was vacuum-dried at low temperature to obtain protocatechualde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com