A kind of preparation method of dibutyltin oxide

A technology of dibutyltin oxide and dibutyltin dichloride, which is applied in the field of preparation of dibutyltin oxide, can solve problems such as coating defects with poor catalytic effect, inability to apply electrophoretic paint, and large product particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

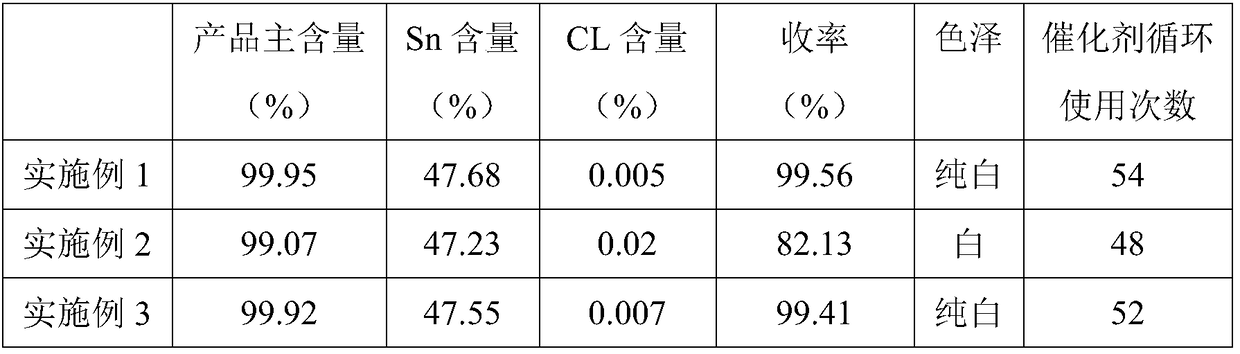

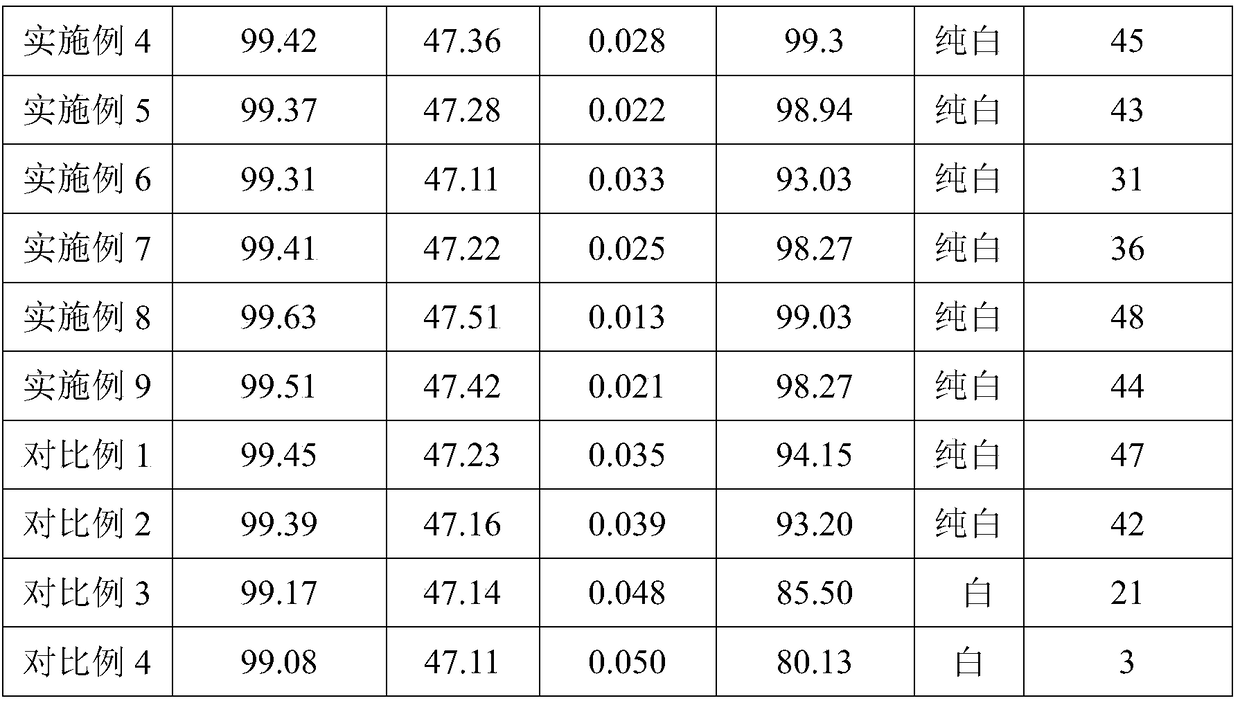

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of dibutyl tin oxide, at least comprise the following steps:

[0033](1) Synthesis of tetrabutyltin: add magnesium powder, composite solvent and n-butyl chloride to the reactor, heat up to reflux for 0.5-1h, slowly add the mixed solution of n-butyl chloride and tin tetrachloride, and reflux for 3h , cooled to room temperature, adding an aqueous hydrochloric acid solution with a mass fraction of 10%, and stirring evenly, separating the organic layer, and concentrating the organic layer under reduced pressure to obtain a colorless liquid tetrabutyltin;

[0034] (2) Synthesis of dibutyltin dichloride: add tetrabutyltin and catalyst in the reactor in step (1), replace with nitrogen 3 times, slowly add tin tetrachloride dropwise, control the temperature in the reaction system to be less than 80°C, After the dropwise addition, keep warm at 60-70°C for 1h, raise the temperature to 135-138°C, keep warm for 3-4h, cool to room t...

Embodiment 1

[0070] The preparation method of dibutyl tin oxide comprises the following steps:

[0071] (1) Synthesis of tetrabutyltin: add magnesium powder, composite solvent and n-butyl chloride in the reactor, heat up to reflux reaction for 0.5h, slowly add dropwise the mixed solution of n-butyl chloride and tin tetrachloride, reflux reaction for 3h, Cool to room temperature, add 10% hydrochloric acid aqueous solution, stir evenly, separate the organic layer, and concentrate the organic layer under reduced pressure to obtain a colorless liquid tetrabutyltin;

[0072] (2) Synthesis of dibutyltin dichloride: add tetrabutyltin and catalyst in the reactor in step (1), replace with nitrogen 3 times, slowly add tin tetrachloride dropwise, control the temperature in the reaction system to be less than 80°C, After the dropwise addition, keep warm at 65°C for 1h, raise the temperature to 136°C, keep warm for 3h, cool to room temperature, add 10% hydrochloric acid aqueous solution, filter, separa...

Embodiment 2

[0084] The preparation method of dibutyl tin oxide comprises the following steps:

[0085] (1) Synthesis of tetrabutyltin: add magnesium powder, composite solvent and n-butyl chloride to the reactor, heat up to reflux reaction for 0.5h, slowly add dropwise the mixed solution of n-butyl chloride and tin tetrachloride, reflux reaction for 3h, Cool to room temperature, add 10% hydrochloric acid aqueous solution, stir evenly, separate the organic layer, and concentrate the organic layer under reduced pressure to obtain a colorless liquid tetrabutyltin;

[0086] (2) Synthesis of dibutyltin dichloride: add tetrabutyltin and catalyst in the reactor in step (1), replace with nitrogen 3 times, slowly add tin tetrachloride dropwise, control the temperature in the reaction system to be less than 80°C, After the dropwise addition, keep warm at 65°C for 1h, raise the temperature to 136°C, keep warm for 3h, cool to room temperature, add 10% hydrochloric acid aqueous solution, filter, separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com