A kind of high temperature resistant ceramic scarlet ink and preparation method thereof

A high-temperature-resistant ceramic and bright red technology, which is applied in the field of high-temperature-resistant ceramic bright red ink and its preparation, can solve the problems of bright red color becoming lighter, not bright enough, and narrow saturation color gamut, etc., to achieve bright colors, improve stability and smoothness And color development, performance index stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] A preparation method of high temperature resistant ceramic scarlet ink, the preparation method comprising:

[0093] The step of preparing the main ingredient: mixing the raw materials for preparing the main ingredient, stirring and dispersing with a dispersing mixer, and then grinding with a grinder using a three-stage flow circulation method to obtain the main ingredient;

[0094] Step of adding ingredients: adding propylene glycol methyl ether, diethylene glycol methyl ether, and diethylene glycol ethyl ether to the main ingredients after grinding, and mixing evenly to obtain a mixture;

[0095] Centrifugation step: the above-mentioned mixture is centrifuged with a centrifuge;

[0096] Multi-stage filtration step: the above-mentioned mixture after centrifugation is filtered through membranes with filter holes of 3 μm, 1 μm, and 1 μm respectively to obtain the finished product of scarlet ink;

[0097] The raw material for preparing the high temperature resistant ceram...

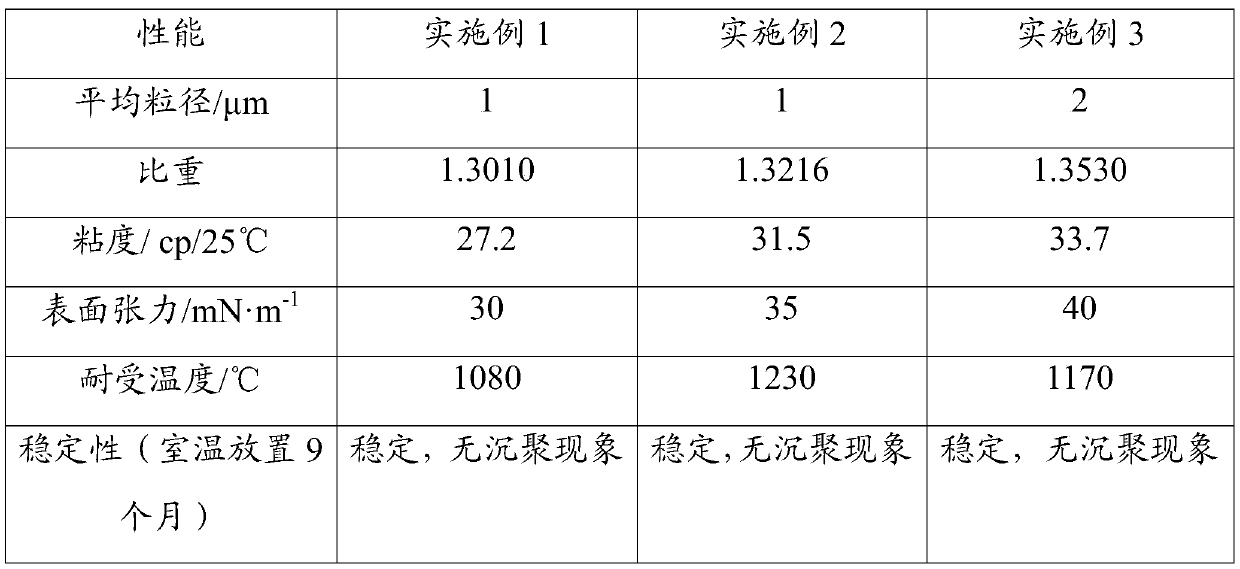

Embodiment 1

[0116] A kind of high temperature resistant ceramic bright red ink, its preparation method comprises:

[0117] The steps of preparing the main ingredient: mix the raw materials for the preparation of the main ingredient and then stir and disperse them with a dispersing mixer. The speed of the dispersing mixer is 1200r / min, and the stirring time is 20min. °C; the grinding time of each stage is controlled to be 1.5 hours, and the rotating speed of the grinding machine is 1400r / min, that is, the main material is obtained;

[0118] Adding batching steps: Add propylene glycol methyl ether, diethylene glycol methyl ether, and diethylene glycol ethyl ether to the above-mentioned main ingredients after grinding, and mix evenly to obtain a mixture. The viscosity of the mixture is cp25cp / 25°C and the surface tension is 30mN / m. The specific gravity is about 1.3010;

[0119] Centrifugation step: the above-mentioned mixture is centrifuged with a centrifuge, the centrifugation volume is co...

Embodiment 2

[0134] A kind of high temperature resistant ceramic bright red ink, its preparation method comprises:

[0135] The steps of preparing the main ingredient: mix the raw materials for the preparation of the main ingredient and then stir and disperse them with a dispersing mixer. The speed of the dispersing mixer is 1400r / min, and the stirring time is 30min. °C; the grinding time of each stage is controlled to be 1.2 hours, and the rotating speed of the grinding machine is 1450r / min, that is, the main material is obtained;

[0136] Steps of adding ingredients: add propylene glycol methyl ether, diethylene glycol methyl ether, and diethylene glycol ethyl ether to the above-mentioned main ingredients after grinding, and mix evenly to obtain a mixture. The viscosity of the mixture is 30cp / 25°C and the surface tension is 35mN / m. The specific gravity is about 1.3216;

[0137] Centrifugation step: the above-mentioned mixture is centrifuged with a centrifuge, the centrifugation volume i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com