A kind of non-spherical microcapsule particle and preparation method thereof

A microcapsule and non-spherical technology, applied in the field of non-spherical microcapsule particles and its preparation, can solve the problems that non-spherical microcapsule particles have not been reported, non-spherical microcapsule particles are rare, etc., and achieve broad research value and application potential. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

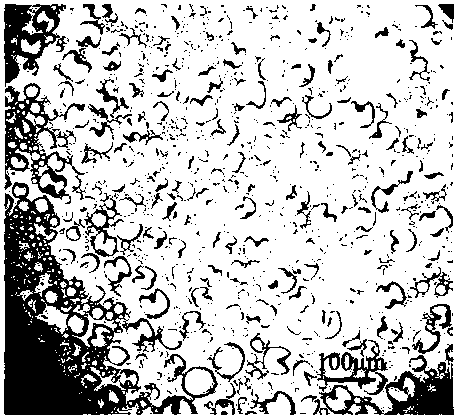

Image

Examples

Embodiment 1 18

[0046] The preparation of embodiment 1 octadecane microcapsule particles

[0047] 1) Take 4.2g of gelatin and 4.2g of gum arabic, dissolve them in 200ml of deionized water, heat to 50°C to dissolve, obtain the first wall material solution and the second wall material solution, and store them at a constant temperature for later use;

[0048] 2) Dissolve 8ml of octadecane in 200ml of deionized water, add 0.5g of Tween 80h and 0.5g of Span 80 at the same time, and stir for 10min at a stirring speed of 450r / min to obtain a uniformly dispersed core material emulsion;

[0049] 3) Mix the core material emulsion prepared in step 2 with the first wall material solution in step 1, and stir for 10 min at a stirring speed of 700 r / min to obtain a single wall material mixed solution;

[0050] 4) Mix the single-wall material mixed solution prepared in step 3 with the second wall material solution in step 1, stir for 10 min at a stirring speed of 520r / min to obtain a double-wall material sol...

Embodiment 2

[0053] The preparation of embodiment 2 fish oil microcapsule particles

[0054] 1) Dissolve 2.5g of gelatin in 200ml of deionized water and heat to 50°C to dissolve to obtain the first wall material solution; weigh 0.25g of chitosan and dissolve it with 20ml of acetic acid solution (1% mass fraction) to obtain the second wall material solution Material solution, kept at constant temperature for later use;

[0055] 2) Dissolve 10ml of fish oil in 200ml of deionized water, add 0.6g of Tween 80 at the same time, and stir for 10min at a stirring speed of 500r / min to obtain a uniformly dispersed core material emulsion;

[0056] 3) Mix the core material emulsion prepared in step 2 with the first wall material solution in step 1, and stir for 10 min at a stirring speed of 800 r / min to obtain a single wall material mixed solution;

[0057] 4) Mix the single-wall material mixed solution prepared in step 3 with the second wall material solution in step 1, and stir for 10 min at a stirr...

Embodiment 3

[0059] The preparation of embodiment 3 citronella essential oil microcapsule particles

[0060] 1) Dissolve 3g of sodium alginate in 200ml of deionized water to obtain the first wall material solution, and dissolve 1.8g of chitosan in 100ml of 1wt% acetic acid solution to obtain the second wall material solution, which is stored at a constant temperature until use.

[0061] 2) Measure 12ml of citronella essential oil and add it to 200ml of deionized water, and at the same time add 0.3g of sodium dodecylsulfonate, and stir at 600r / min for 10min to obtain a uniformly dispersed core material emulsion.

[0062] 3) Mix the core material emulsion prepared in step 2 with the first wall material solution in step 1, and stir for 10 min at a stirring speed of 850 r / min to obtain a single wall material mixed solution.

[0063] 4) Mix the single-wall material mixed solution prepared in step 3 with the second wall material solution in step 1, stir for 10 min at a stirring speed of 520r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com