Preparation method of special raw material glass for high performance borosilicate foam glass

A foam glass and high-performance technology, applied in the field of borosilicate foam glass preparation, can solve the problems of poor acid corrosion resistance, low mechanical strength, and failure to reach large-scale production, and achieve good airtightness of pores, good acid corrosion resistance, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

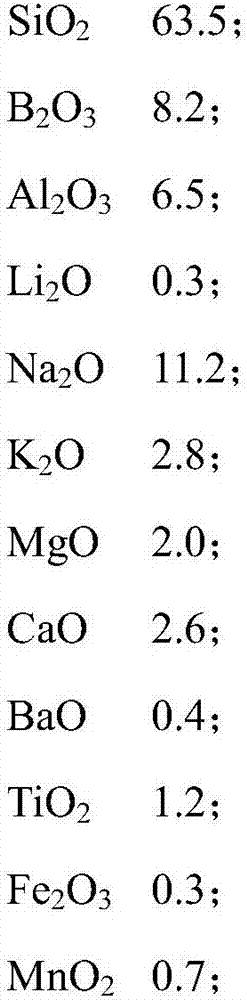

Embodiment 1

[0024] A method for preparing special raw material glass for high-performance borosilicate foam glass, comprising the following steps:

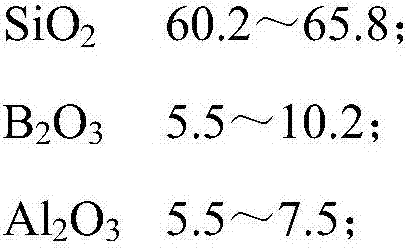

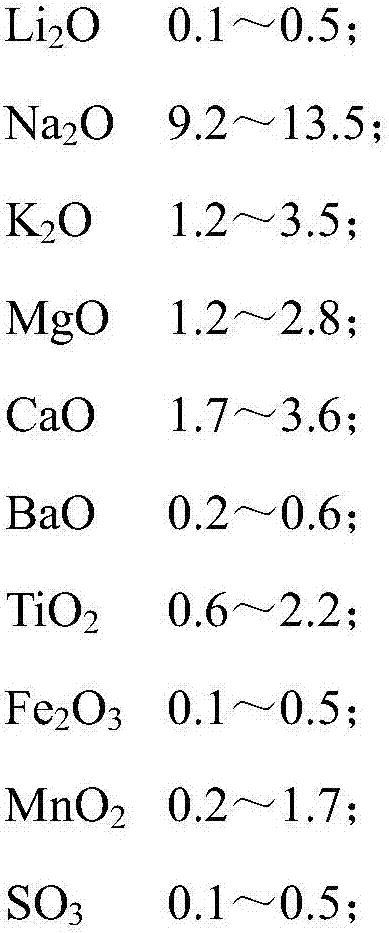

[0025] (1) Ingredients: According to the designed material recipe, weigh all kinds of raw materials and mix them uniformly in the mixer; wherein, in terms of mass percentage, the composition of each raw material is:

[0026]

[0027]

[0028] (2) Melting: The prepared raw materials are heated at high temperature to form a uniform glass liquid without bubbles; this is a very complicated physical and chemical reaction process. The melting of glass is carried out in a melting furnace, which adopts energy-saving Type glass industrial flame pool kiln, the mixture is melted in the kiln pool, and the open flame is heated on the glass liquid surface; the melting temperature of the glass is 1300-1600 °C; it is melted into fluid glass liquid, and enters the material through the working part of the pool kiln. Road, the molten glass is gradually lo...

Embodiment 2

[0042] Change the formula of raw material in the step (1) in the embodiment 1 to be (in mass percentage):

[0043]

[0044] Prepare two groups of cellular glass products, one group is the common cellular glass (every group of 5 samples) bought on the market, and another group is the foamed glass (every group of 5 samples) of the glass of the present invention as raw material foaming, respectively in Soaked in dilute sulfuric acid for 20 days, the quality changes are as shown in Table 3:

[0045] table 3

[0046] name Original mass g Mass g after 20 days Increase and decrease rate Foam glass foamed from ordinary glass raw materials 20 20.8~21.6 ≥4% Glass of the present invention is the foamed glass of raw material foaming 20 20.015~20.035 ≤0.175%

[0047] Other technical performance indicators are shown in Table 4:

[0048] Table 4

[0049] Technical performance index value value Measured Bulk density ≤150kg / m 3

Embodiment 3

[0051] Change the formula of raw material in the step (1) in the embodiment 1 to be (in mass percentage):

[0052]

[0053] Prepare two groups of cellular glass products, one group is the common cellular glass (every group of 5 samples) bought on the market, and another group is the foamed glass (every group of 5 samples) of the glass of the present invention as raw material foaming, respectively in Soaked in dilute sulfuric acid for 20 days, the quality changes are as shown in Table 3:

[0054] table 3

[0055] name Original mass g Mass g after 20 days Increase and decrease rate Foam glass foamed from ordinary glass raw materials 20 20.8~21.6 ≥4% Glass of the present invention is the foamed glass of raw material foaming 20 20.013~20.033 ≤0.165%

[0056] Other technical performance indicators are shown in Table 4:

[0057] Table 4

[0058] Technical performance index value value Measured Bulk density ≤150kg / m 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com