A zrc ceramic material surface zrb 2 The preparation method of -sic composite coating

A technology of composite coating and ceramic material, which is applied in the preparation of ZrB2-SiC based composite ceramic coating and the preparation of ZrB2-SiC based composite ceramic coating on the surface of ZrC ceramic composite material, can solve the high temperature protection performance of ZrC ultra-high temperature ceramics Poor problems, good chemical compatibility, good combination, and obvious application advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific implementation mode one: this implementation mode comprises the following steps:

[0021] 1. Mole percentage is Zr:B 4 C: Si=1:0.456:0.368 Weigh zirconium powder, boron carbide powder and silicon powder for wet mixing by ball milling, and obtain slurry after mixing;

[0022] 2. Evaporate and dry the slurry on a rotary evaporator, and grind to obtain a mixed powder;

[0023] 3. Put the mixed powder in a vacuum hot-pressing sintering furnace, carry out hot-pressing sintering under the protection of an inert gas, and take it out after cooling with the furnace to obtain ZrB 2 - SiC-ZrC ultra-high temperature ceramic body material;

[0024] Four, the ceramic green body obtained in step 3 is crushed, ground and sieved to obtain ZrB 2 , SiC and ZrC mixed spray powder;

[0025] 5. Carry out surface pretreatment to the ZrC-SiC multiphase ceramic matrix to obtain the pretreated ZrC-SiC matrix;

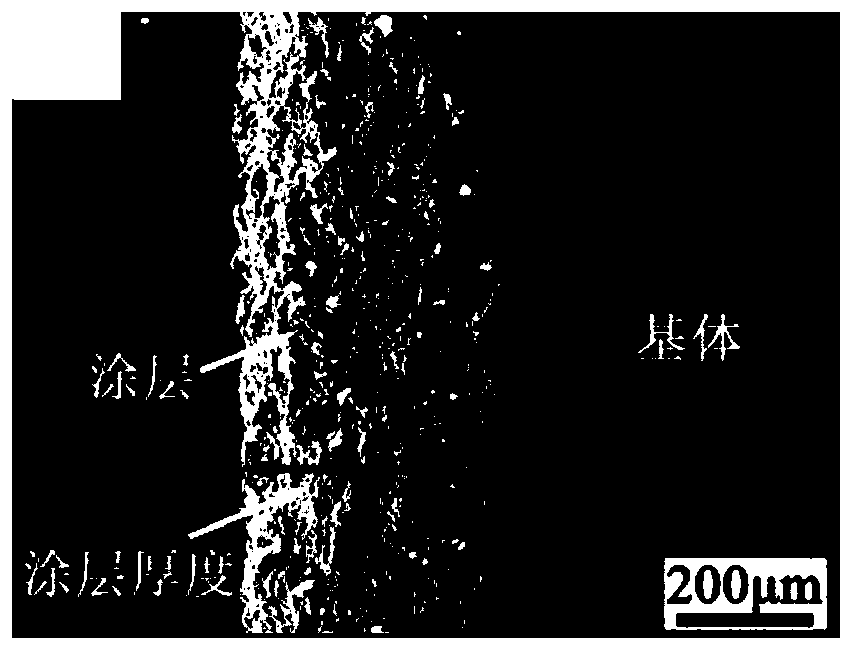

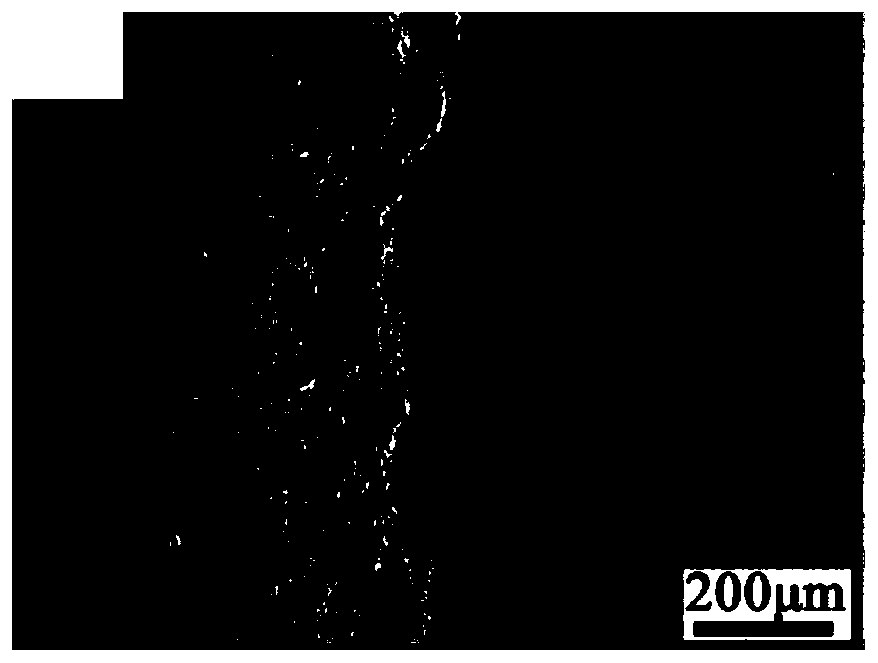

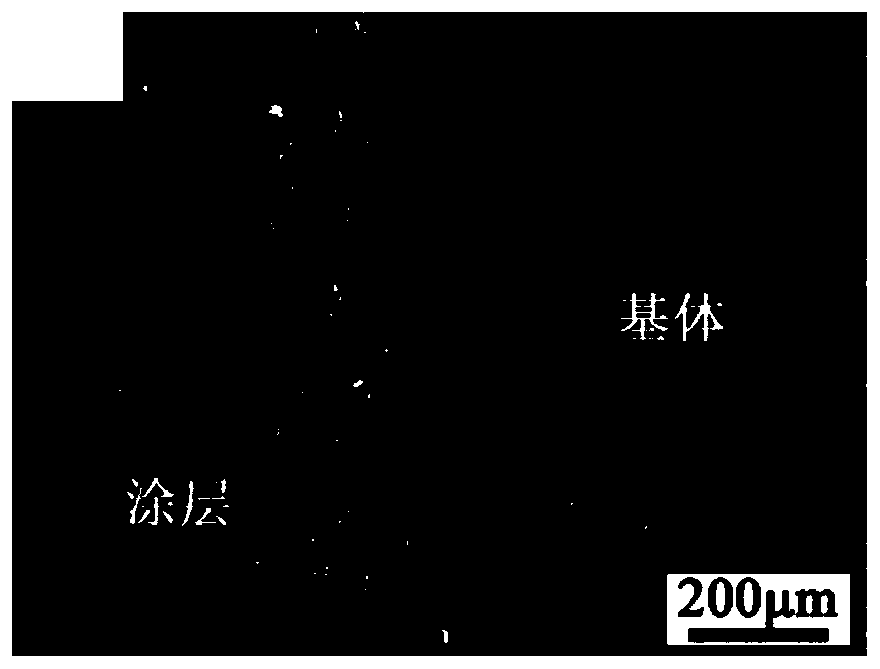

[0026] Six, adopt plasma spraying technology to prepare coating, the Zr...

Embodiment 1

[0037] Select commercially available zirconium powder, boron carbide powder and silicon powder as preparation ZrB 2 , SiC and ZrC spray powder raw material powder, zirconium powder, boron carbide powder and silicon powder raw material powder by mole percentage as Zr:B 4 C: Si = 1: 0.456: 0.368 to weigh, and then put it into a ball mill jar, with absolute ethanol as dispersant, ZrO 2The ball is used as a ball milling medium, and is wet ball milled and mixed for 14 hours on a planetary ball mill at a speed of 350 r / min. The slurry mixed uniformly by ball milling was dried on a rotary evaporator under the drying conditions of a rotating speed of 75r / min and a temperature of 80°C, and then was ground to obtain a mixed powder. Put the mixed powder into a graphite mold, place it in a vacuum hot-press sintering furnace, and sinter in an argon atmosphere. Raise the temperature to 1000°C at a rate of 4°C / min and hold for 60 minutes; then raise the temperature to 1250°C at a rate of 4...

Embodiment 2

[0039] Select commercially available zirconium powder, boron carbide powder and silicon powder as preparation ZrB 2 , SiC and ZrC spray powder raw material powder, zirconium powder, boron carbide powder and silicon powder raw material powder by mole percentage as Zr:B 4 C: Si = 1: 0.456: 0.368 to weigh, and then put it into a ball mill jar, with absolute ethanol as dispersant, ZrO 2 The ball is used as a ball milling medium, and is wet ball milled and mixed for 14 hours on a planetary ball mill at a speed of 350 r / min. The slurry mixed uniformly by ball milling was dried on a rotary evaporator under the drying conditions of a rotating speed of 75r / min and a temperature of 80°C, and then was ground to obtain a mixed powder. Put the mixed powder into a graphite mold, place it in a vacuum hot-press sintering furnace, and sinter in an argon atmosphere. Raise the temperature to 1000°C at a rate of 4°C / min and hold for 60 minutes; then raise the temperature to 1250°C at a rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com