Silicon-alkyne hybrid high-temperature-resistant polymer containing hydrogen on side chain and preparation method thereof

A high-temperature-resistant polymer and hydrogen-containing silicon technology, applied in the field of organic polymer materials, can solve the problems of limited material development space and application range, poor molding and processing performance, and few active groups, so as to improve molding processing performance and durability High temperature capability, improvement of heat resistance, effect of lowering curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a side-chain hydrogen-containing silane hybrid high-temperature-resistant polymer, characterized in that it comprises the following steps:

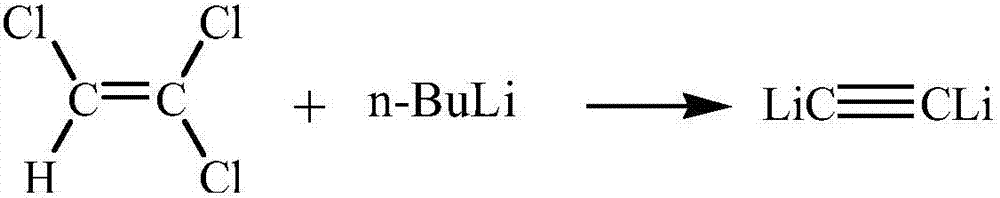

[0025] Step 1: Under the protection of an inert gas, react trichlorethylene with butyl lithium to synthesize ethynyl dilithium;

[0026]

[0027] Step 2: Under the protection of an inert gas, react dichlorosilane with the ethynyl dilithium synthesized in step 1 to synthesize ethynyl-silane;

[0028]

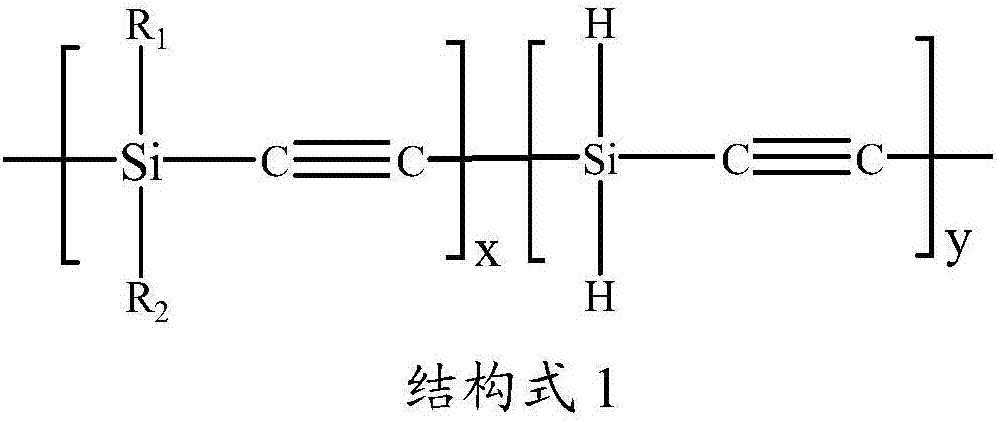

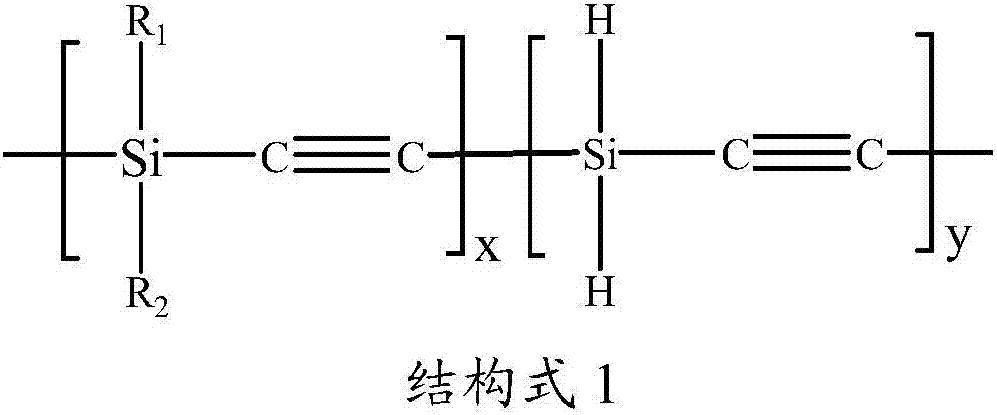

[0029] Where: R 1 , R 2 is phenyl or vinyl;

[0030] Step 3: Under the protection of an inert gas, react trifluoromethanesulfonic acid with the ethynyl-silane synthesized in step 2 to obtain trifluoromethanesulfonated ethynyl-silane with activated side chain;

[0031]

[0032] where R 1 , R 2 is phenyl or vinyl; any integer of x≥0, any integer of y>0;

[0033] Step 4: Under the protection of an inert gas, react sodium borohydride with the trifluoromethanesulfonated ethynyl-silane generated in step...

Embodiment 1

[0047] Prepare a kind of side chain hydrosilyne hybrid high temperature resistant polymer (wherein, R 1 , R 2 Both are vinyl; x=0)

[0048] Under the protection of high-purity nitrogen, add 16.7mL of butyllithium, 10mL of tetrahydrofuran and 10mL of anhydrous ether into a four-necked flask, control the temperature of the system at -20 to -40°C, and drop 1.2mL of trichlorohydrin through a constant pressure dropping funnel. Ethylene, after the dropwise addition, the system was kept at this temperature for 2 hours. Then, the temperature was controlled at -20 to -40° C., and a solution of 1.9 mL of divinyldichlorosilane and 10 mL of tetrahydrofuran was added dropwise. After the dropwise addition, the system was kept at this temperature for 2 hours. Then control the temperature at -10 to -40°C, continue to slowly add a solution of 2.4mL trifluoromethanesulfonic acid and 20mL tetrahydrofuran dropwise, keep the system at this temperature for 3 hours after the dropwise addition, and...

Embodiment 2

[0052] Prepare a kind of side chain hydrosilyne hybrid high temperature resistant polymer (wherein, R 1 , R 2 Both are phenyl groups; x=0)

[0053] Under the protection of high-purity nitrogen, add 16.7mL of butyllithium, 10mL of tetrahydrofuran and 10mL of anhydrous ether into a four-necked flask, control the temperature of the system at -20 to -40°C, and drop 1.2mL of trichlorohydrin through a constant pressure dropping funnel. Ethylene, after the dropwise addition, the system was kept at this temperature for 2 hours. Then, the temperature was controlled at -20 to -40°C, and a solution of 2.8 mL of diphenyldichlorosilane and 10 mL of tetrahydrofuran was added dropwise. After the dropwise addition, the system was kept at this temperature for 3 hours. Then control the temperature at -10 to -40°C, continue to slowly add a solution of 2.4mL trifluoromethanesulfonic acid and 20mL tetrahydrofuran dropwise, keep the system at this temperature for 3 hours after the dropwise additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com