Preparation method capable of realizing aspergillus niger spore multiplication through carrier adsorption and producing xerospore powder of aspergillus niger

A technology of Aspergillus niger spores and Aspergillus niger, which is applied to the dry compound protective agent of Aspergillus niger spore powder and the field of drying and porous carrier adsorption of Aspergillus niger spore proliferation, which can solve the problems of high instrument cost, long drying time, and activity change, and achieve The effect of large number of proliferation and fast growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] A preparation method for aspergillus niger spore proliferation by carrier adsorption;

[0092] (1) Preparation of Aspergillus niger spore proliferation culture medium:

[0093] Mix corn and bran in a ratio of 7:3 by weight, and mix corn bran with water according to the volume ratio of the total weight of solids to water as 1:5, and mix amylase with 12 units per gram of corn weight Add it to the above mixture to liquefy, boil at 100°C for 30 minutes, filter, and the filtrate will be dissolved to the original volume of water added to obtain the culture solution of Aspergillus niger spores;

[0094] (2) Preparation of Aspergillus niger spore culture by solid-state fermenter carrier:

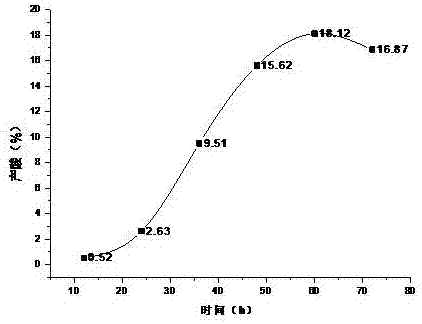

[0095] will be crushed into a volume of 1cm 3 The corn cob cores were mixed with the above-mentioned Aspergillus niger culture solution at a weight-to-volume ratio of 1:3.5, put into a solid-state fermenter, sterilized at 121°C for 20 minutes, cooled to 37°C and inserted with Aspergillus ni...

Embodiment 2

[0101] A preparation method for aspergillus niger spore proliferation by carrier adsorption;

[0102] (1) Preparation of Aspergillus niger spore proliferation culture medium:

[0103] Mix corn and bran in a ratio of 7:3 by weight, and mix corn bran with water according to the volume ratio of the total weight of solids to water as 1:5, and mix amylase with 12 units per gram of corn weight Add it to the above mixture to liquefy, boil at 100°C for 30 minutes, filter, and the filtrate will be dissolved to the original volume of water added to obtain the culture solution of Aspergillus niger spores;

[0104] (2) Preparation of Aspergillus niger spore culture by solid-state fermenter carrier:

[0105] will be crushed into a volume of 1cm 3 The corn cob cores were mixed with the above-mentioned Aspergillus niger culture solution at a weight-to-volume ratio of 1:3.5, put into a solid-state fermenter, sterilized at 121°C for 20 minutes, cooled to 37°C and inserted with Aspergillus ni...

Embodiment 3

[0112] Aspergillus niger spore fermentation production citric acid prepared by the present invention:

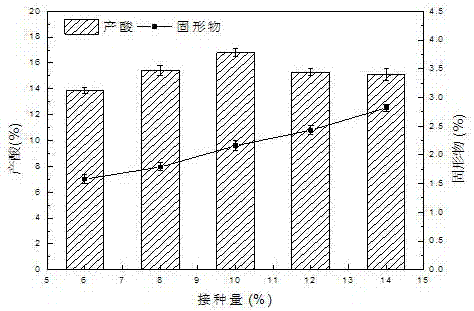

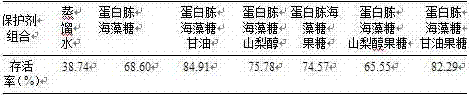

[0113] Citric acid is an important organic acid, widely used in food, medicine, chemical industry and other industries It is the first acid agent used, accounting for more than 60% of the amount of food acidulant. The dry spore powder provided by the invention is used for inoculation and fermentation of citric acid factories to produce citric acid. And determine the optimal inoculation amount.

[0114] (1) Preparation of fermentation medium:

[0115] Corn liquid with dregs provided by the cooperative citric acid company. Add the slag-bearing corn liquid into the fermenter with a liquid volume of 8%, and sterilize it at 121°C for 20 minutes.

[0116] (2) Production of citric acid:

[0117] The dry spore powder provided by the present invention is inserted into the fermenter, and the inoculum amount is 6%, 8%, 10%, 12%, and 14%, respectively, and the inoculum amount is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com