A kind of organic light-emitting display panel and preparation method thereof

A light-emitting display, organic light-emitting device technology, applied in semiconductor/solid-state device manufacturing, coating, electric solid device and other directions, can solve the problems of weak adhesion, unfavorable device bending, thick inorganic layer, etc., to achieve good elasticity and toughness, Good seismic performance and surface can resist the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

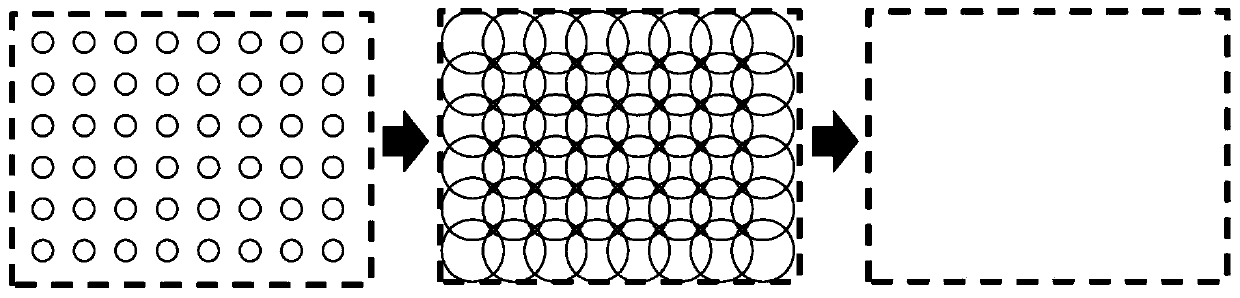

Examples

preparation example Construction

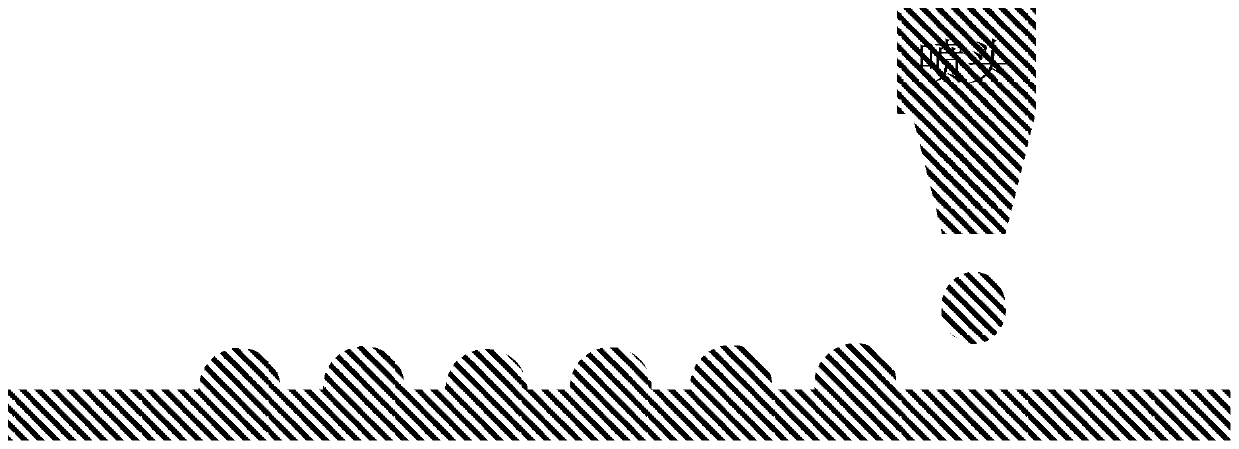

[0105] The preparation method of the inorganic barrier layer may illustratively include any one of sputtering, chemical vapor deposition, metal-organic chemical vapor deposition, plasma chemical vapor deposition, atomic evaporation, and electron cyclotron resonance.

[0106] In a specific embodiment, the material of the inorganic encapsulation layer is silicon nitride or aluminum oxide.

[0107] In a specific embodiment, the organic encapsulation layer is formed by inkjet printing.

[0108] The present invention also provides a method for preparing an organic light-emitting display panel, the method comprising the following steps:

[0109] Provide the substrate;

[0110] forming an organic light emitting device on the substrate;

[0111] An encapsulation layer is formed on the side of the organic light-emitting device away from the substrate, the encapsulation layer includes at least one organic encapsulation layer, and the organic encapsulation layer is obtained by cross-li...

Embodiment 1

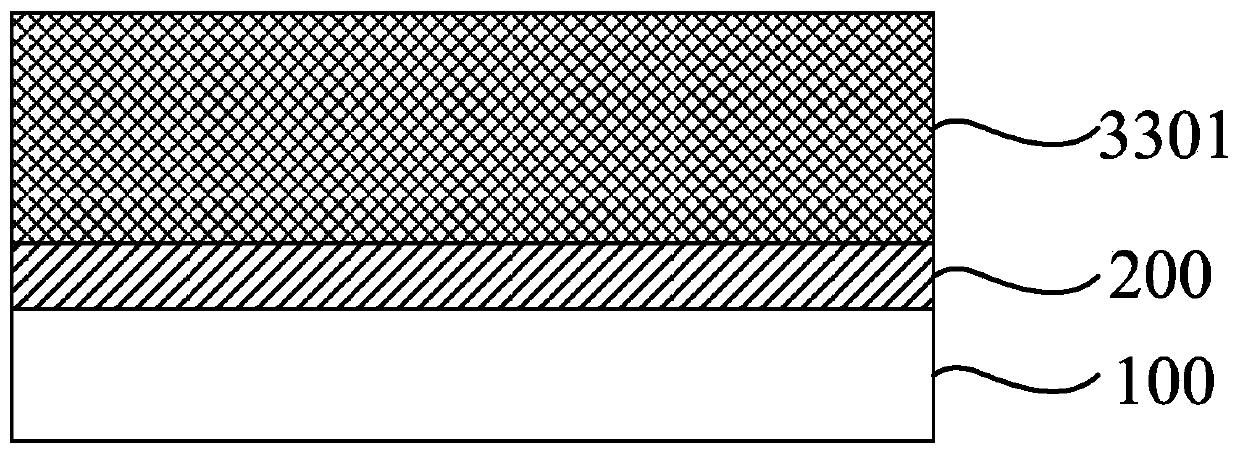

[0119] A kind of organic light-emitting display panel (structure such as image 3 shown), including a silicon substrate, an organic light emitting device (OLED) 200 disposed on one side of the silicon substrate 100, and an encapsulation layer covering the OLED 200, the encapsulation layer is a first organic encapsulation layer 3301, and the organic encapsulation layer Layer 300 is a polymer with a network structure obtained by crosslinking polyorganosiloxane;

[0120] The raw materials of the polymer with network structure obtained by polyorganosiloxane crosslinking include:

[0121] (i) blocks have The structure of polyorganosiloxane, the degree of polymerization is 20, The siloxane unit accounts for 80% of the total number of polysiloxane siloxane repeating units; 50 parts by weight;

[0122] (ii) The block has The structure of polyorganosiloxane, the degree of polymerization is 20, The siloxane unit accounts for 80% of the total number of polysiloxane siloxane repe...

Embodiment 2

[0130] The difference from Example 1 is that the raw materials of the polymer with a network structure obtained by crosslinking polyorganosiloxane include:

[0131] (i) blocks have The structure of polyorganosiloxane, the degree of polymerization is 20, The siloxane unit accounts for 80% of the total number of polysiloxane siloxane repeating units; 80 parts by weight;

[0132] (ii) The block has The structure of polyorganosiloxane, the degree of polymerization is 20, The siloxane unit accounts for 80% of the total number of polysiloxane siloxane repeating units; 15 parts by weight;

[0133] (iii) 2,4,6-trichloro-s-triazine, 5 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com