Magnetic polystyrene-base chitosan compound adsorbent and preparation method and application thereof

A polystyrene-based, composite adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problem of reducing the content of active adsorption functional groups of modified chitosan, affecting the modified Chitosan adsorption performance, reducing adsorption capacity and other issues, to achieve the effect of easy industrial expansion of production, good recycling performance, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take a 250mL four-necked flask, add 90mL of deionized water to it, and pass nitrogen protection at room temperature (to remove the oxygen in the water body), then weigh 10g of styrene monomer and 1.0g of acrylic acid monomer and add them to the deionized water. After stirring for about 10 minutes, weigh 100mg of potassium persulfate and dissolve it in 5mL of deionized water, add it to the above solution, raise the temperature to about 75°C, use mechanical stirring at a speed of 140-150rpm, and continue the reaction for 20h to terminate the reaction. Centrifuge the obtained carboxylated polystyrene microsphere solution at 12,000 rpm for more than 35 minutes, then wash with water, sonicate, and centrifuge again, repeat three times, and finally dry in a 60°C oven to obtain a white solid.

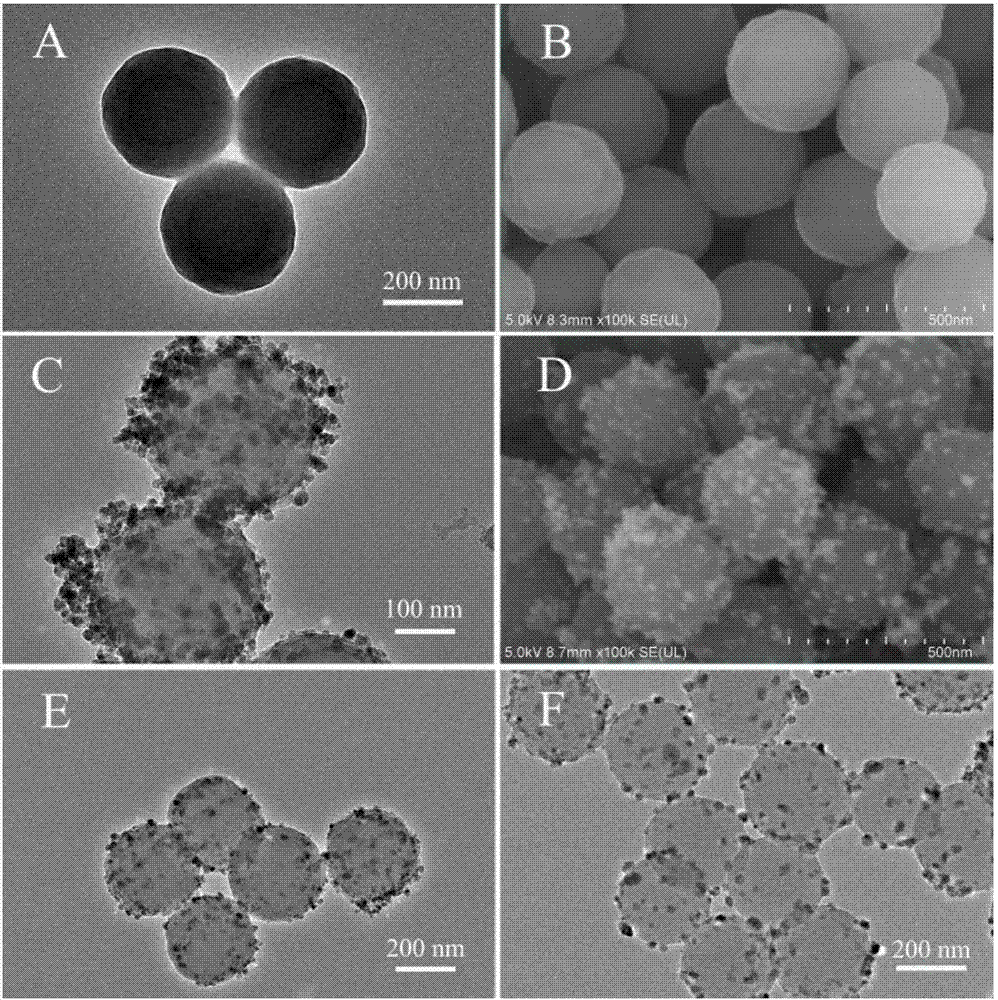

[0033] Magnetic carboxylated polystyrene composite microspheres were prepared by co-precipitating Fe 3 o 4 Nanoparticles evenly cover the surface of polystyrene microspheres. The exper...

Embodiment 2

[0038] The preparation method of magnetic polystyrene-based chitosan composite adsorbent specifically comprises the following steps:

[0039] Step (1): Add styrene monomer and acrylic acid monomer into deionized water, stir and mix, then add persulfate aqueous solution, raise the temperature to 65°C, stir and react for 20 hours, then centrifuge to retain the solid matter, and then After washing with water, ultrasonication, and drying, a white solid was obtained, that is, carboxylated polystyrene microspheres;

[0040] Step (2): ultrasonically disperse the carboxylated polystyrene microspheres prepared in step (1) in deionized water to form an emulsion, protect it with an inert gas, place it in an ice-water bath, and then add dissolved FeCl 3 ·6H 2 O and FeCl 2 4H 2 O aqueous solution, keep stirring for 1 hour, remove the ice-water bath, and then place it in a water bath at 85°C to observe the color change of the emulsion. After the color of the emulsion turns dark yellow, a...

Embodiment 3

[0054] The preparation method of magnetic polystyrene-based chitosan composite adsorbent specifically comprises the following steps:

[0055] Step (1): Add styrene monomer and acrylic acid monomer into deionized water, stir and mix, then add persulfate aqueous solution, heat up to 76°C, stir and react for 12 hours, then centrifuge to retain solid matter, and then After washing with water, ultrasonication, and drying, a white solid was obtained, that is, carboxylated polystyrene microspheres;

[0056] Step (2): ultrasonically disperse the carboxylated polystyrene microspheres prepared in step (1) in deionized water to form an emulsion, protect it with an inert gas, place it in an ice-water bath, and then add dissolved FeCl 3 ·6H 2 O and FeCl 2 4H 2 O aqueous solution, keep stirring for 0.5 hours, remove the ice-water bath, and then place it in a water bath at 80°C to observe the color change of the emulsion. After the color of the emulsion turns dark yellow, add ammonia wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com