Electrostatic spinning-carbonization preparation method of foldable flexible pure nanometer carbon fiber

A carbon nanofiber and electrospinning technology, which is applied in the field of pure carbon nanofiber membrane material and its preparation, can solve the problems of unsatisfactory practical use, unsatisfactory battery electrochemical performance, poor flexibility and mechanical strength of carbon nanofiber, etc., and achieves excellent performance. The effect of flexibility, simple preparation method, and easy reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Use an analytical balance to accurately weigh zinc acetate (Zn(Ac) 2 ) And polyacrylonitrile (PAN) powder (among which Zn(Ac) 2 , PAN mass ratio 0.4:1, and PAN molar mass M = 100000g / mol, mass fraction 8%) placed in a 20ml sample bottle, use a pipette to accurately pipette 10ml of NN dimethylformamide (DMF) , The sample bottle is sealed with raw material tape, heated to 100℃, stirred for 48 hours, and finally a uniform Zn(Ac) is obtained 2 / PAN Electrospinning Solution.

[0036] Electrospinning equipment is used to prepare nanofiber membranes, which are pre-oxidized at 200°C and carbonized at 1000°C to prepare foldable, flexible and pure carbon nanofibers.

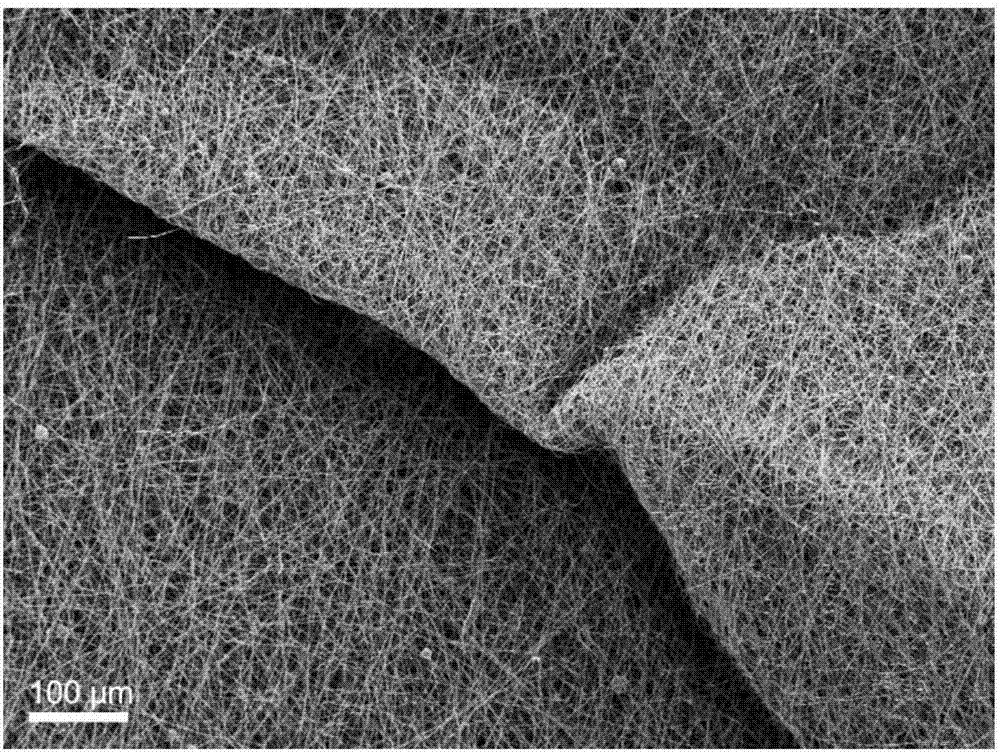

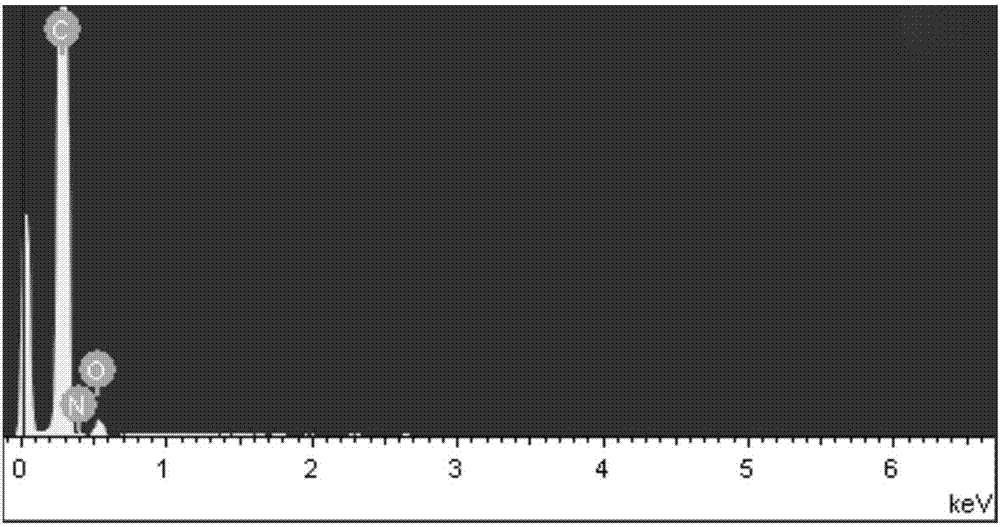

[0037] The SEM scanning electron micrograph of the carbon nanofibers prepared in Example 1 is shown in figure 1 , Through SEM scanning electron microscopy combined with energy spectrum analysis found that Example 1: Zn(Ac) 2 , PAN mass ratio 0.4:1, stirring temperature 100 ℃, pre-oxidation temperature 200 ℃, carbonization...

Embodiment 2

[0040] Use an analytical balance to accurately weigh zinc carbonate (ZnCO 3 ) And polyacrylonitrile (PAN) powder (where ZnCO 3 , The mass ratio of PAN is 1:1, and the molar mass of PAN is M=100000g / mol, the mass fraction is 8%) Put it in a 20ml sample bottle, and use a pipette to accurately pipette 10ml of NN dimethylformamide (DMF) , The sample bottle is sealed with raw material tape, heated to 20℃, stirred for 240 hours, and finally a uniform ZnCO 3 / PAN Electrospinning Solution.

[0041] Electrospinning equipment is used to prepare nanofiber membranes, which are pre-oxidized at 240°C and carbonized at 800°C to prepare foldable, flexible and pure carbon nanofibers.

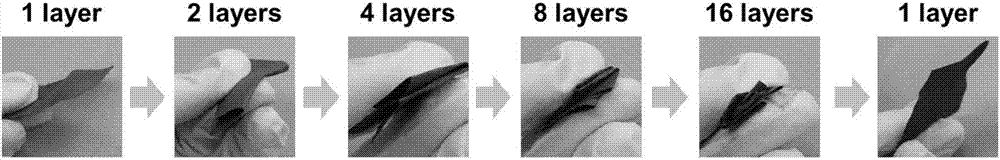

[0042] Cut the nano-carbon fiber obtained in Example 2 into a 5*5cm square, and fold it in half from the center for the first time, and then fold it in half for the second time until it folds in half four times, each time it is recorded by a photo , See Figure 4 The results show that the carbon nanofiber prepared in...

Embodiment 3

[0044] Use an analytical balance to accurately weigh zinc methacrylate and polyacrylonitrile (PAN) powder (the mass ratio of zinc methacrylate to PAN is 0.5:1, and the molar mass of PAN is M = 100000 g / mol, and the mass fraction is 8%). In a 20ml sample bottle, use a pipette to accurately pipette 10ml of NN dimethylformamide (DMF). The sample bottle is sealed with a raw material tape, heated to 60℃, stirred for 96 hours, and finally uniform methacrylic acid is obtained. Zinc / PAN electrospinning solution.

[0045] Electrospinning equipment is used to prepare nanofiber membranes, which are pre-oxidized at 270°C and carbonized at 650°C to prepare foldable flexible pure carbon nanofibers.

[0046] Cut the carbon nanofiber obtained in Example 3 into a 5*5cm square for the first half-folding from the center, and then perform the second half-folding on this basis, until the half-folding four times, each time it is recorded by a photo , See Figure 4 The results show that the carbon nanof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com