Manufacturing method of composite blade with gradient function

A composite blade, gradient function technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of high hardness surface layer, material mechanical properties and gradient change of microstructure in a single direction, etc., to achieve low cost , The effect of excellent surface quality of parts and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

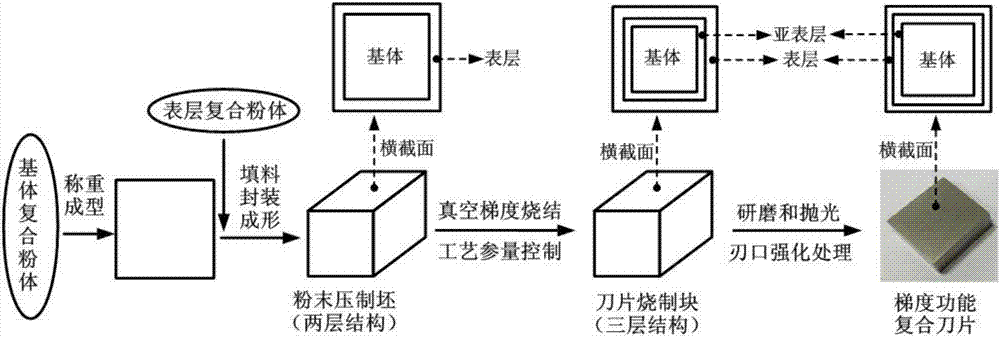

[0039] Embodiment: A kind of manufacturing method of gradient function composite cutting tool, the main process is as follows figure 1 shown, including the following steps:

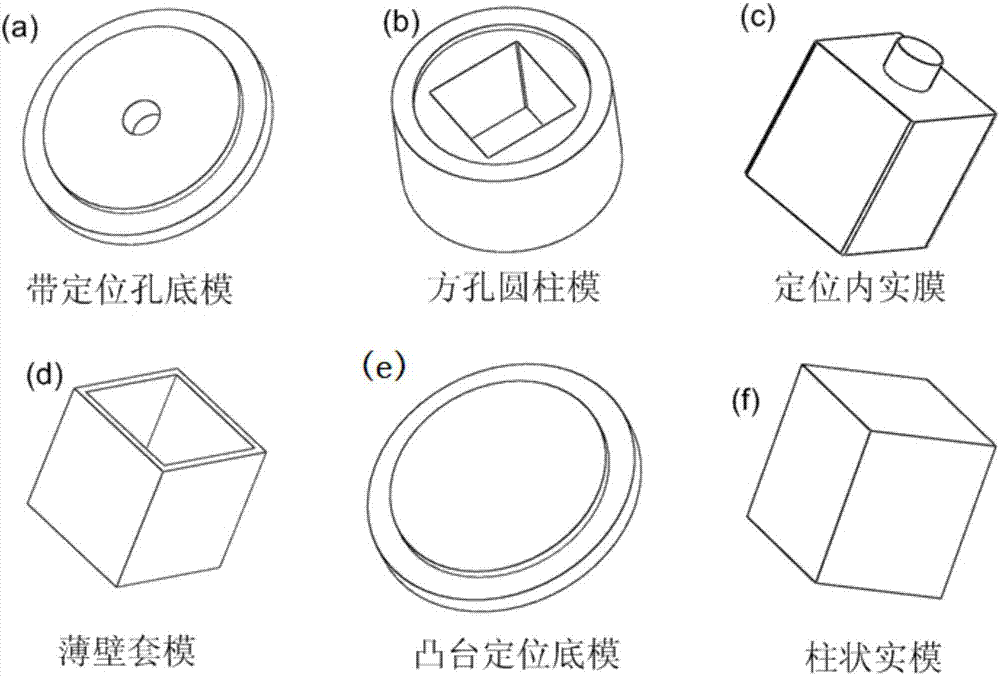

[0040] (1) Fill the composite powder into the prefabricated mold successively;

[0041] (2) cold-pressing the powder loaded into the mold to make a blade powder blank, which includes a two-layer structure of a surface layer and a matrix;

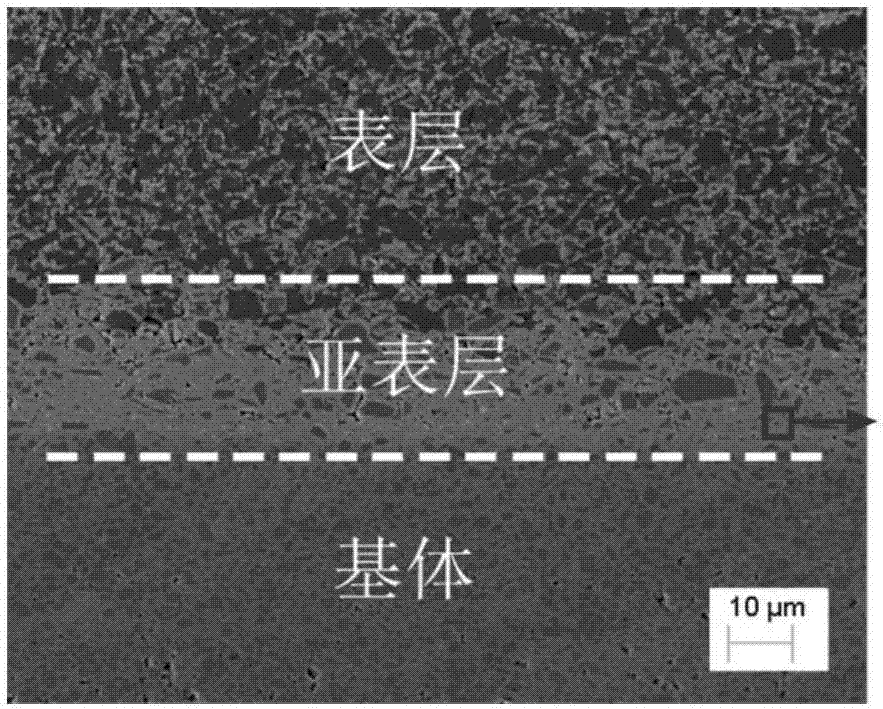

[0042] (3) Putting the pressed blade powder compact into a vacuum sintering chamber for gradient sintering to prepare a blade compact, which includes a three-layer structure of a surface layer, a subsurface layer and a matrix;

[0043] (4) Grinding, polishing and edge treatment are carried out on the sintered blade block green body to manufacture a composite blade with gradient function.

[0044] The above steps are as follows:

[0045] (1) The tool material components are shown in Table 1.

[0046] Table 1 Ratio of tool material components (wt%)

[0047]

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com