Benzotriazole compound ultraviolet absorber and its preparation method and application

A technology of benzotriazole and compounds, which is applied in the field of new benzotriazole compounds, can solve the problems of lack of active groups, affecting the anti-ultraviolet durability of fabrics, etc., to improve wearing experience, excellent anti-ultraviolet function, and overcome easy The effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

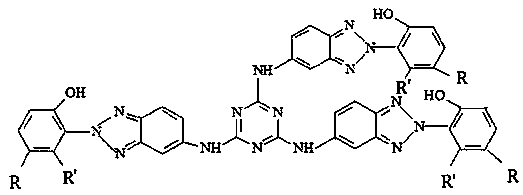

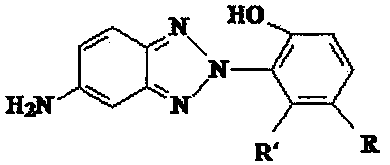

Method used

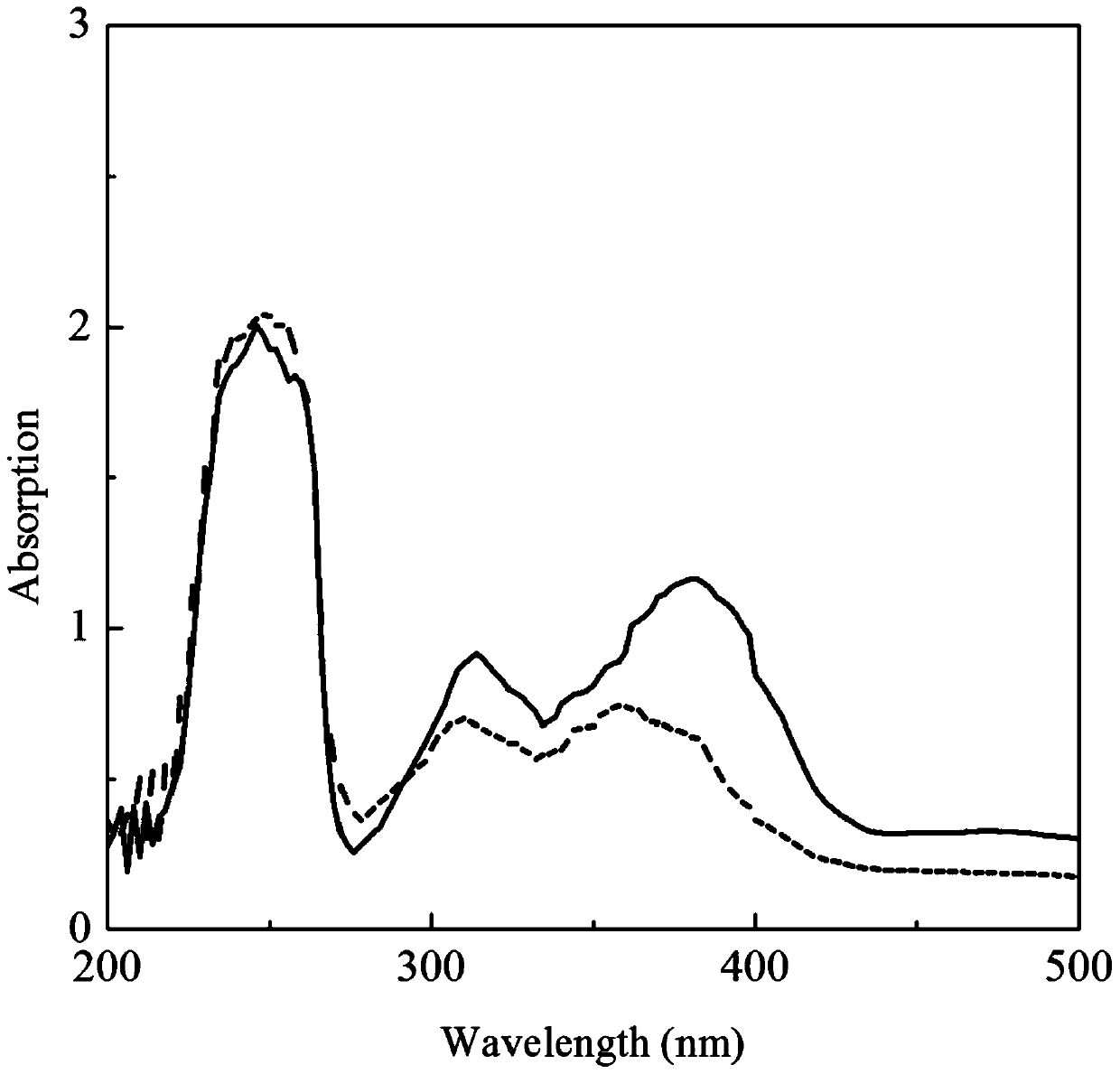

Image

Examples

Embodiment 1

[0024] 100mL there-necked bottle, add 1.84g cyanuric chloride to 30mL water, fully stir to form a uniform suspension, then slowly dropwise add 6.75g of 2-(2-hydroxyphenyl)-5-aminobenzotriazole in the there-necked bottle For sodium hydroxide solution, the optimal rate of dropping is controlled at 0.5-1ml / min. During the dropping, react at a temperature of 0-5°C for 2 hours, then raise the temperature to 40°C, and react for 2 hours. At a temperature of 80°C, React for 6 hours. After the reaction, cool to room temperature, pour the reaction solution into water, and a yellow solid precipitates out. Let stand, filter with suction, wash with water, ethanol, and acetone, and dry to obtain a light yellow solid powder. Wherein, the sodium hydroxide solution can also be potassium hydroxide solution, sodium bicarbonate solution or sodium carbonate solution, and the acid generated by the dropwise equilibrium reaction;

[0025] Anti-ultraviolet finishing of polyester fabrics:

[0026] Its...

Embodiment 2

[0029] 100mL there-necked bottle, add 1.84g cyanuric chloride to 30mL water, stir well to form a uniform suspension, then slowly add dropwise sodium hydroxide containing 7.17g of 2-(2-hydroxyphenyl)-5-aminobenzotriazole Solution, the best rate of dropping is controlled at 0.5-1ml / min, during the dropping, react at 0-5°C for 2h, then raise the temperature to 60°C, react for 2h, and react at 90°C for 5h, After the reaction, the reaction solution was poured into water, and a yellow solid precipitated out. After standing still, suction filtration, washing with water, ethanol and acetone, and drying, a light yellow solid powder was obtained. Wherein, the sodium hydroxide solution can also be potassium hydroxide solution, sodium bicarbonate solution or sodium carbonate solution, and the acid generated by the dropwise equilibrium reaction;

[0030] Anti-ultraviolet finishing of polyester fabrics:

[0031] The composition of the finishing agent includes light yellow solid powder obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com