Preparation method for sodium alginate nanometer fiber-based hydrogel

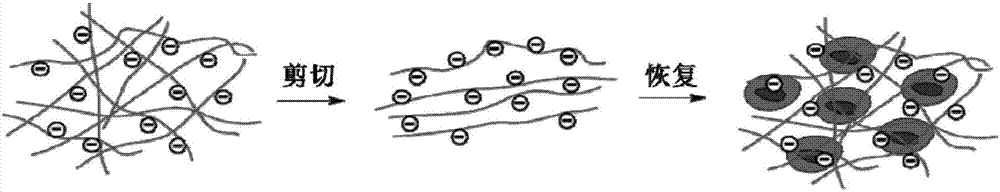

A technology of nanofibers and sodium alginate is applied in the preparation of sodium alginate nanofiber-based hydrogel and the field of preparation of sodium alginate hydrogel, which can solve the complex preparation process, poor extrusion performance index, and biological side effects. and other problems, to achieve the effect of simple preparation method, easy implementation and strong thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method is as follows:

[0059] In the first step, use deionized water to prepare a sodium alginate nanofiber solution with a concentration of 0.1% by mass;

[0060] In the second step, while stirring, add NaCl to the above-mentioned nanofiber solution until the concentration of the NaCl (electrolyte) component in the mixed solution reaches 500mM;

[0061] Then, through phase separation, the fibrous sodium alginate hydrogel is obtained.

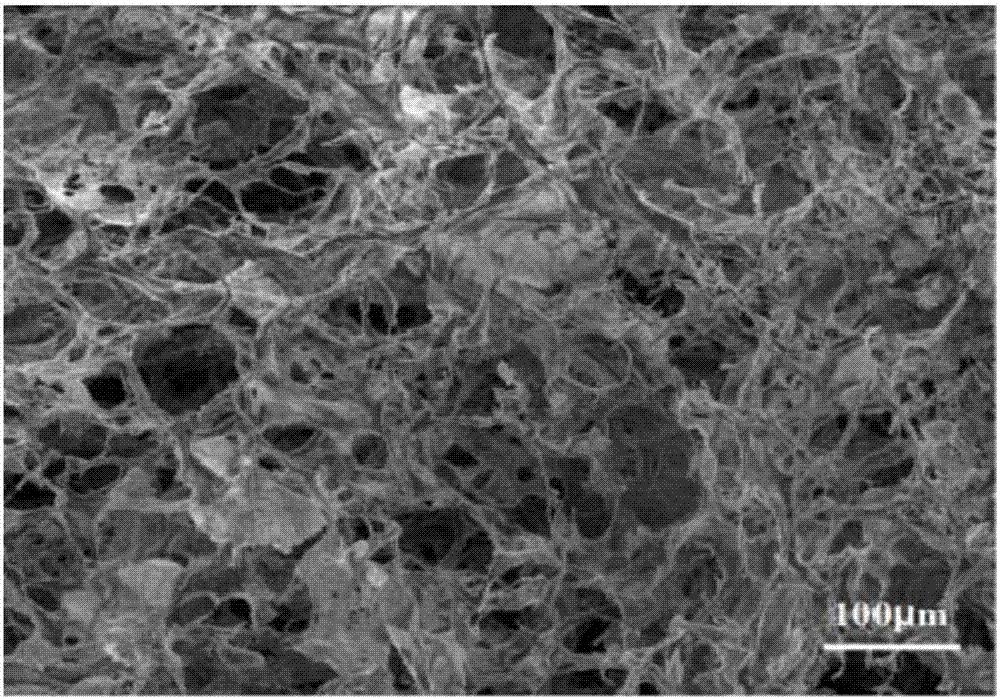

[0062] After testing, the content of sodium alginate nanofibers in the prepared fibrous sodium alginate hydrogel is 1%;

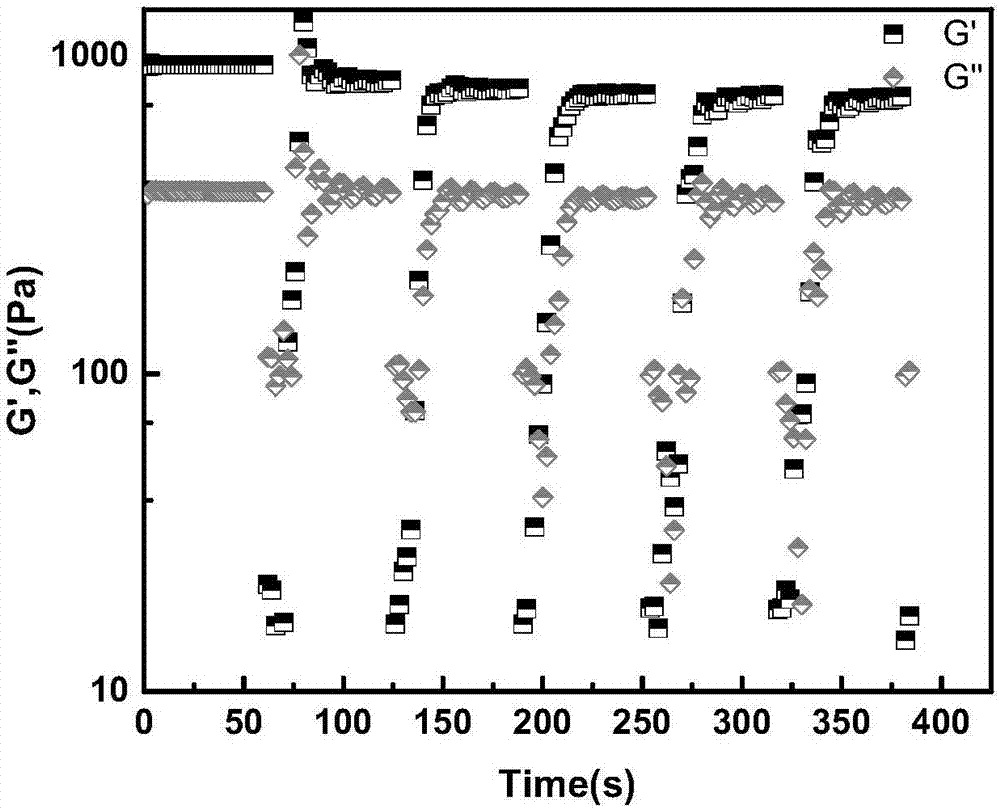

[0063] The storage modulus of sodium alginate nanofiber translucent hydrogel is 2000Pa, and it has good thixotropy. It is found that it can withstand 5000% strain and the recovery rate of storage modulus after 50 times of shearing Can be maintained at 90%.

Embodiment 2

[0065] The preparation method is as follows:

[0066] In the first step, use deionized water to prepare a sodium alginate nanofiber solution with a concentration of 2.5% by mass;

[0067] In the second step, while stirring, add Na to the above-mentioned nanofiber solution 2 CO 3 , until the Na in the mixed solution 2 CO 3 The concentration of the ingredients reaches 200mM;

[0068] Then, through phase separation, the sodium alginate nanofiber translucent hydrogel is obtained.

[0069] After testing, in the prepared sodium alginate nanofiber translucent hydrogel, the content of sodium alginate nanofiber is 4%;

[0070] The storage modulus of sodium alginate nanofiber translucent hydrogel is 7000Pa, and it has good thixotropy, and it is found that it can withstand 5000% strain and the recovery rate of storage modulus after 50 times of shearing Can be maintained at 92%.

Embodiment 3

[0072] The preparation method is as follows:

[0073] In the first step, use deionized water to prepare a sodium alginate nanofiber solution with a concentration of 3.5% by mass;

[0074] In the second step, while stirring, add Na to the above-mentioned nanofiber solution 2 SO 4 , until the Na in the mixed solution 2 SO 4 The concentration of the ingredients reaches 100mM;

[0075] Then, through phase separation, the sodium alginate nanofiber translucent hydrogel is obtained.

[0076] After testing, in the prepared translucent hydrogel of sodium alginate nanofibers, the content of sodium alginate nanofibers is 6%;

[0077] The storage modulus of sodium alginate nanofiber translucent hydrogel is 18000Pa, and it has good thixotropy, can withstand 5000% strain, and after 50 shears, the recovery rate of storage modulus can be maintained At 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com