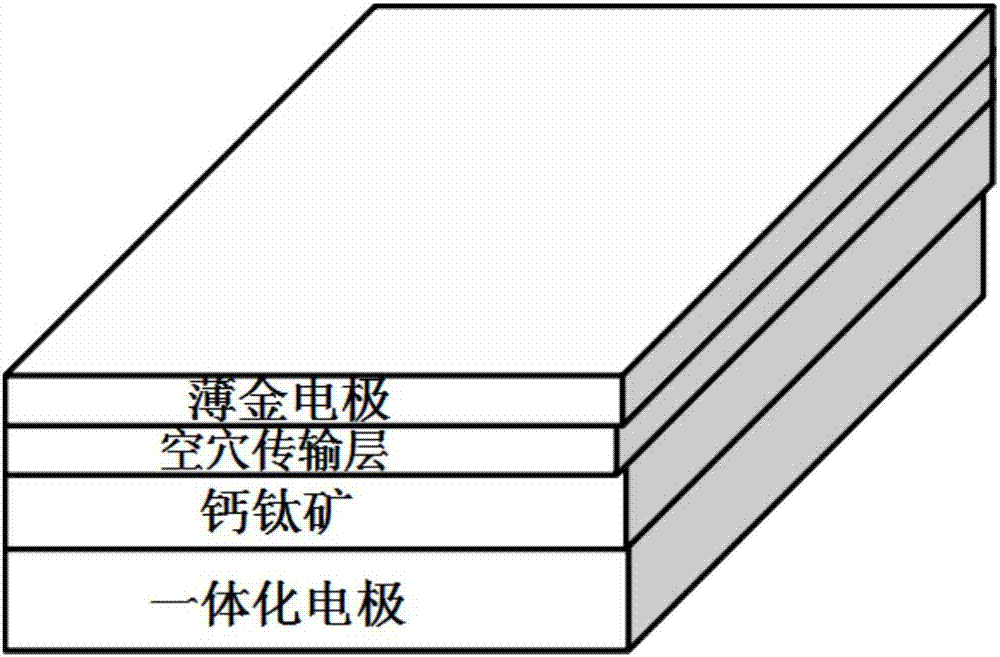

In-situ prepared substrate, dense layer and porous layer integrated perovskite solar cell and method thereof

A solar cell and in-situ preparation technology, applied in the field of solar cells, can solve the problems of high price, complex preparation process, and limited efficiency, and achieve the effect of low cost, simple cell structure, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

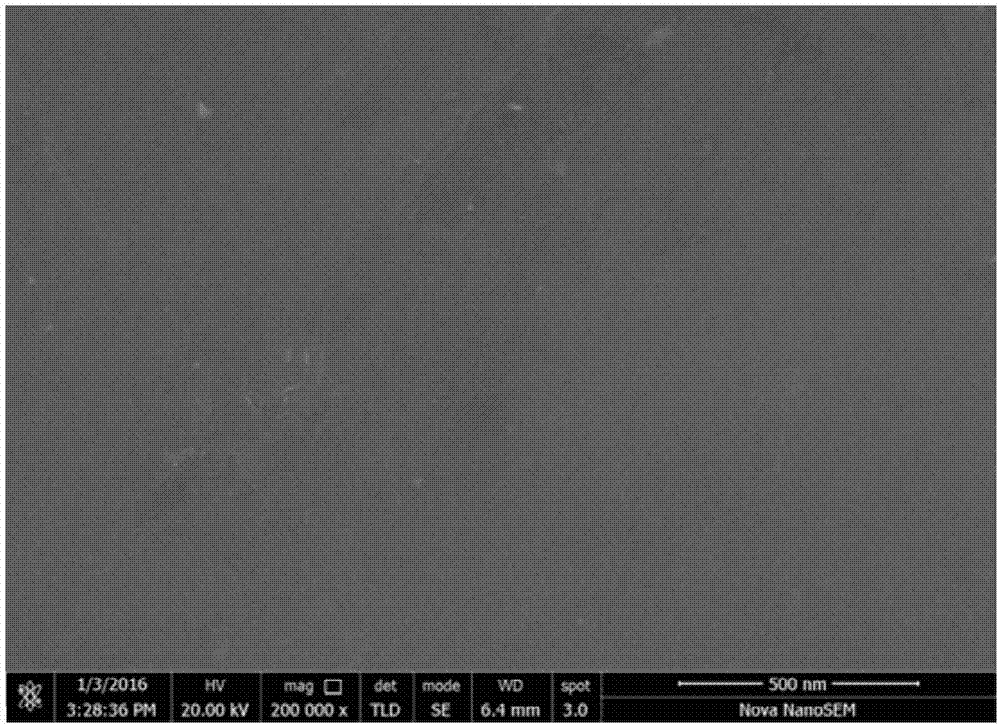

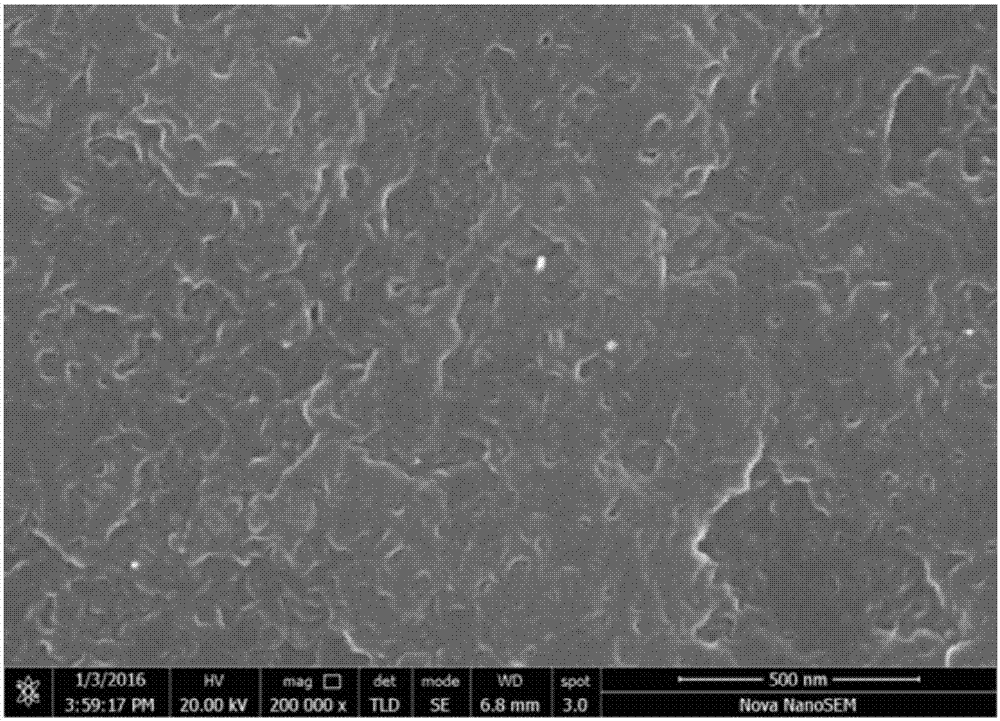

[0039] Take the metal base and cut the base into 2*2cm 2 Sand the rectangle with 3000 mesh, 5000 mesh, and 7000 mesh sandpaper for several hours in order to smooth the surface and remove oxides on the metal surface. Clean the metal substrate sequentially with acetone, isopropanol, ethanol, and deionized water for 10-30 minutes in a washing tank, then take out the substrate and dry it with nitrogen gas for storage. Prepared surface topography see figure 2 . To prepare the electron transport layer with a porous structure, the substrate needs to be placed in 1-5M sulfuric acid, etched at 30-90° C. for 1-3 hours, rinsed and dried, and then used. Sinter the etched substrate in a muffle furnace at 300-600°C for 1-5 hours, and cool down naturally until the substrate cools down. The surface electron microscope of the formed porous morphology can be seen image 3 . Sand the edge of the substrate with sandpaper to make a certain edge for electrode testing. In this way, the integra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com