Li<21>Si<5>/C composite material, preparation method and application

A composite material and compound technology, which is applied in the field of preparing nano-Li21Si5 and carbon composite electrode materials, can solve problems such as reduction, and achieve the effects of good process stability, simple operation and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

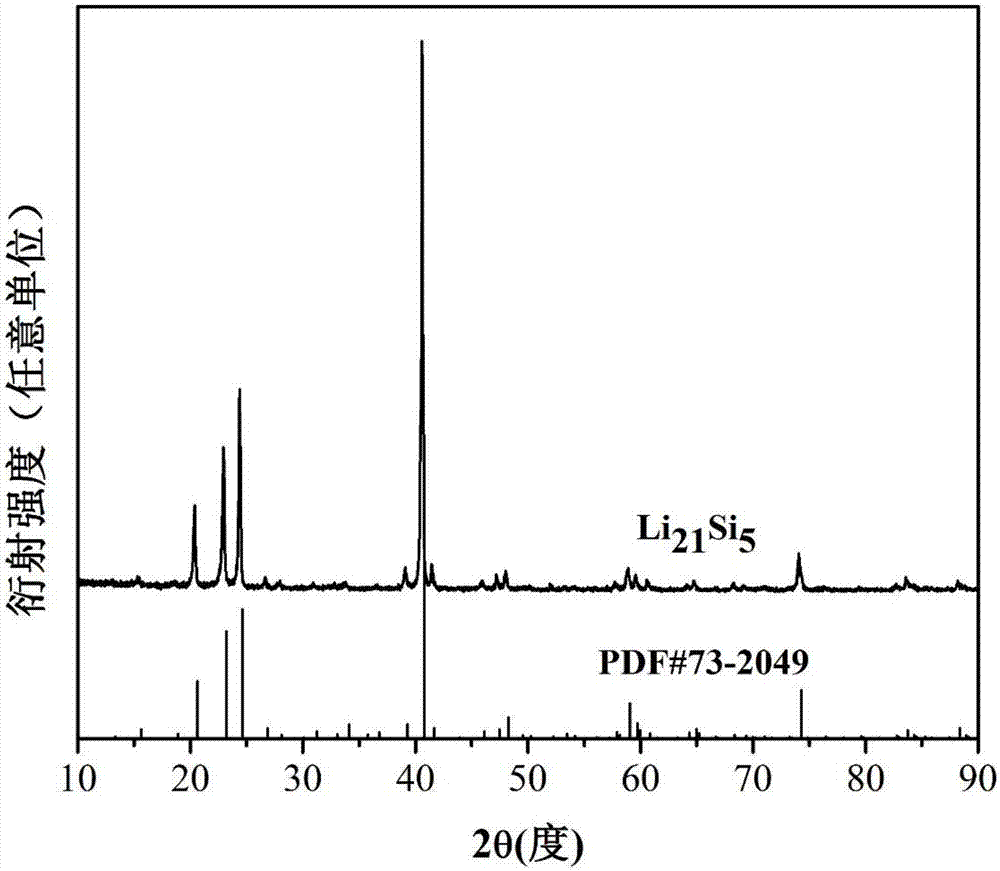

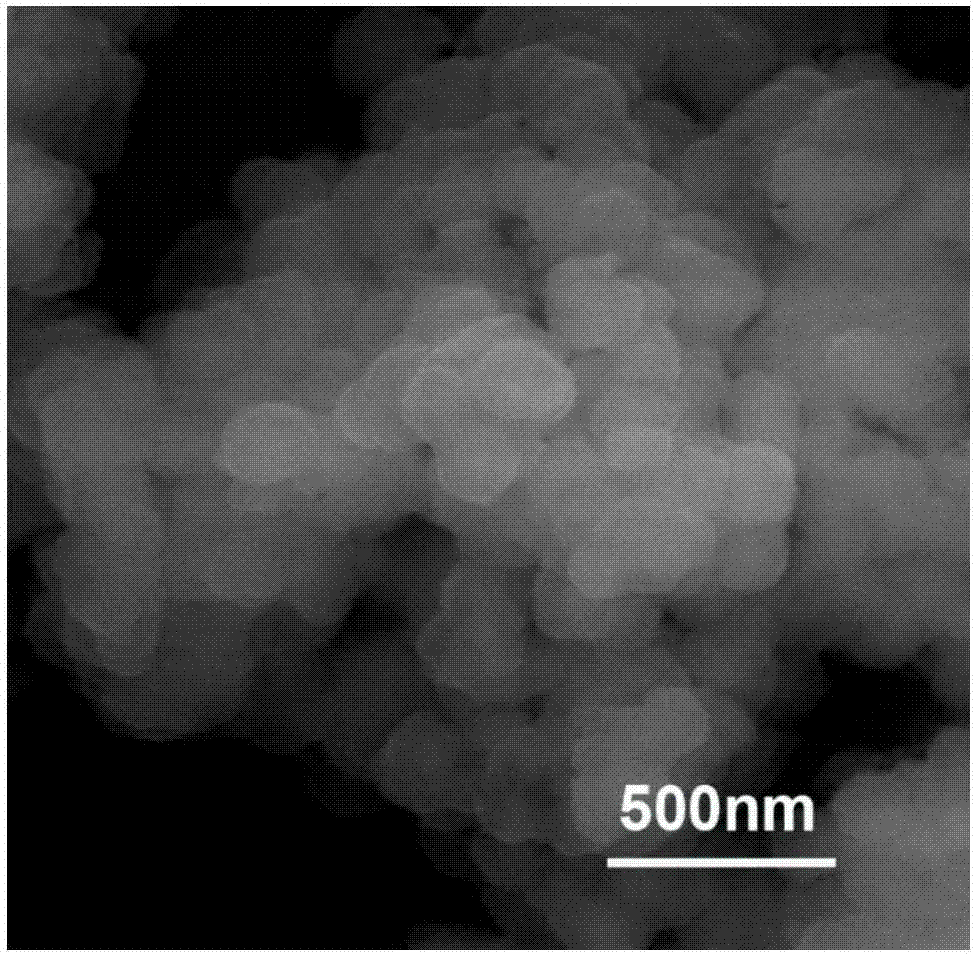

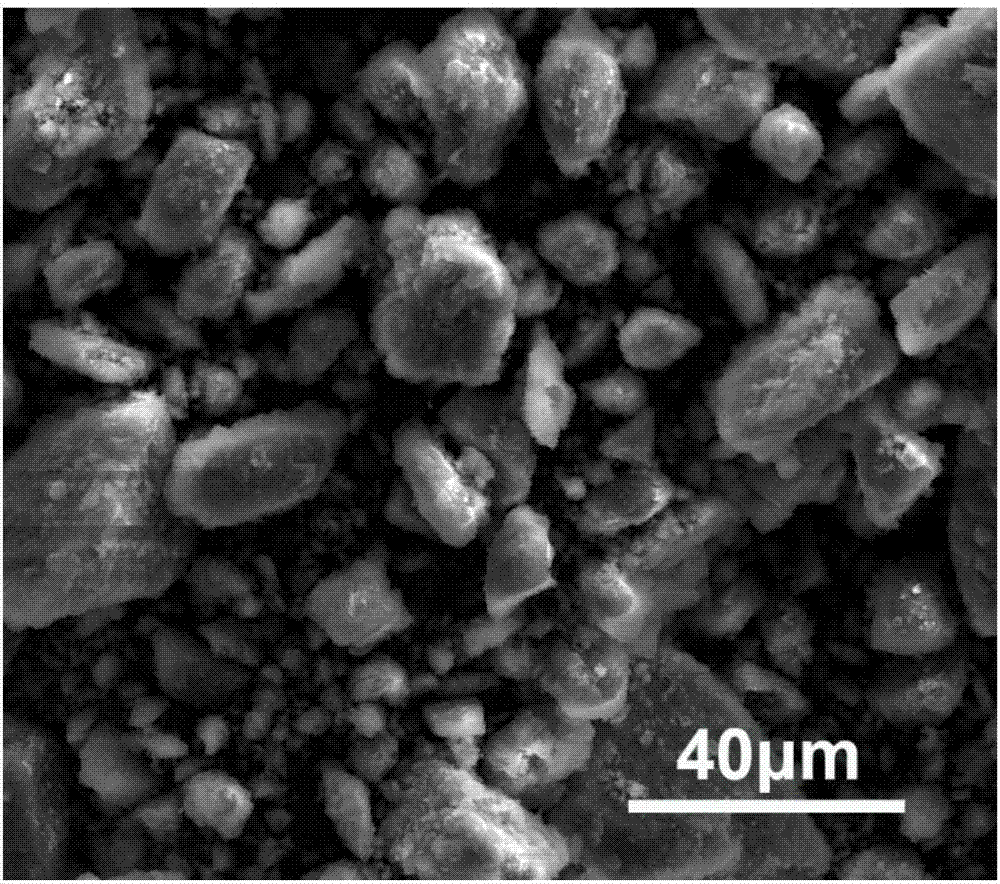

[0026] Silicon nanoparticles with an average particle size of 50 nm were heated to 100 °C under vacuum to remove the adsorbed gas and moisture, and then according to Li 21 Si 5 Compound composition distribution ratio, weigh 280mg dried silicon nanoparticles and 308mg lithium flakes in an argon glove box, put them into a tantalum crucible, then move the silicon nanoparticles, lithium flakes and tantalum crucible into a stainless steel ball mill jar, In an argon-protected environment, the silicon nanoparticles and lithium flakes were magnetically stirred in a tantalum crucible with an external magnetic stirrer. At the same time, the stainless steel ball mill was heated to 200 ° C and kept for 9 hours. The average particle size was thus prepared. 200 nm Li 21 Si 5 Particles, whose phase analysis results are as follows figure 1 As shown, its microscopic appearance is as figure 2 Shown; the above-prepared Li 21 Si 5 The particles are mixed with acetylene black with a mass ra...

Embodiment 2

[0028] Silicon nanoparticles with an average particle size of 70 nm were heated to 150 °C under vacuum to remove the adsorbed gas and moisture, and then according to Li 21 Si 5 Compound composition ratio, weigh 300mg dried silicon nanoparticles and 330mg lithium flakes in an argon glove box, put them into a tantalum crucible, then move the silicon nanoparticles, lithium flakes and tantalum crucible into a stainless steel ball mill tank, In an argon-protected environment, the silicon nanoparticles and lithium flakes were magnetically stirred in a tantalum crucible with an external magnetic stirrer, and at the same time, the ball mill jar was heated to 230°C and kept for 6 hours. The average particle size obtained was about 280 nm Li 21 Si 5 Particles; the above-prepared Li 21 Si 5Particles are mixed with acetylene black with a mass ratio of 20%. The ball milling process is as follows: the ball-to-material ratio is 20:1, the ball milling speed is 500r / min, and the ball milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com