Lanthanum molybdate-based intermediate-temperature solid oxide fuel cell electrolyte material and preparation method thereof

A technology of solid oxides and electrolyte materials, which can be used in solid electrolytes, fuel cells, non-aqueous electrolytes, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

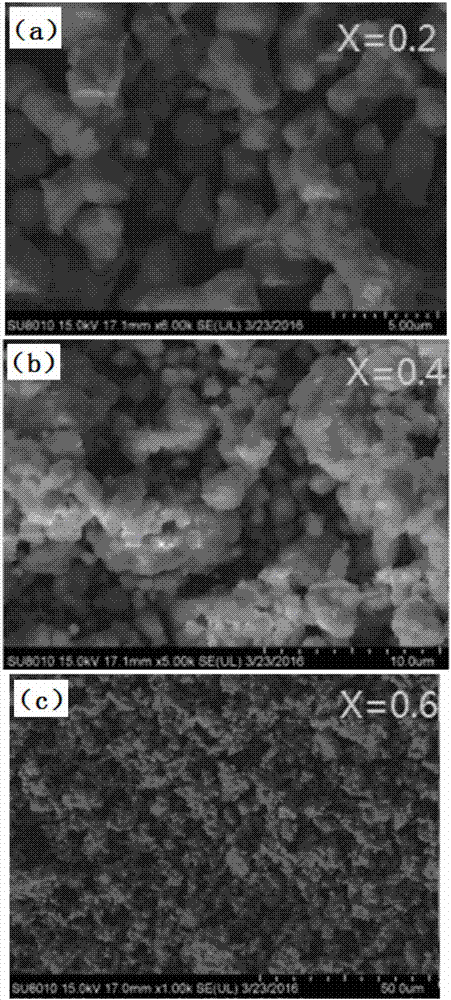

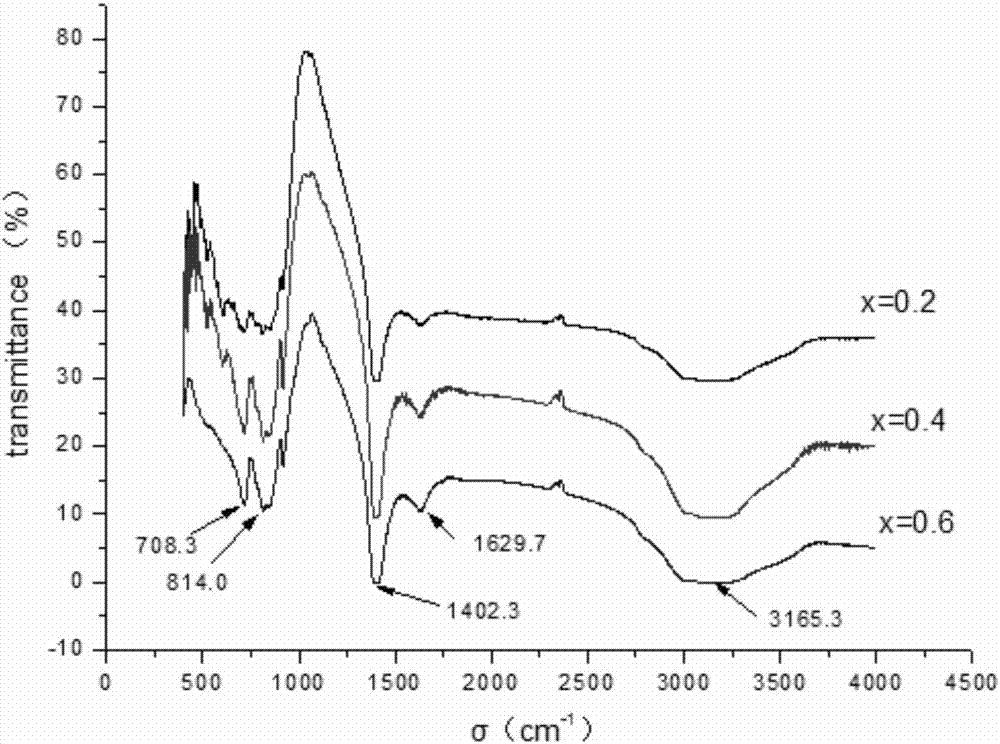

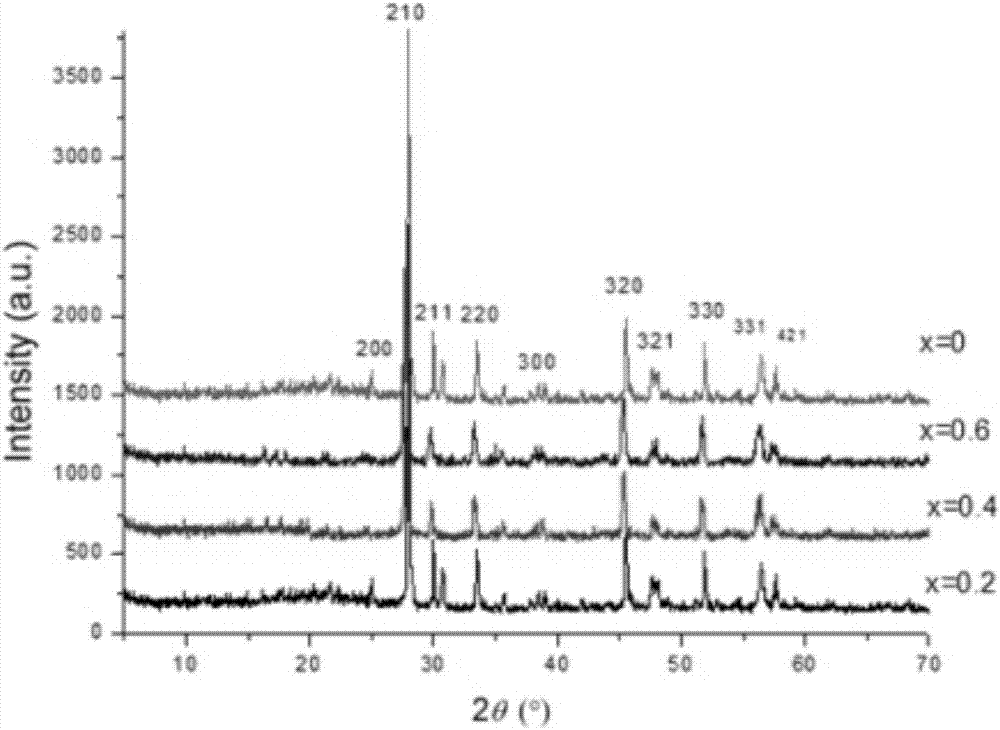

[0019] According to La 2 o 3 、MoO 3 The molar ratio between CuO and CuO is 1:1.8:0.2 Weigh the material, use absolute ethanol as the medium, mix the material into the mortar, use KEQ-D-P all-round planetary ball mill to grind for 3 hours, and the fineness is controlled at 10μm The following; then transfer the material to a crucible, put it in a muffle furnace, and calcine in air for 10 hours at a calcination temperature of 950°C; after calcination, take it out and grind it sufficiently to finally obtain a solid precursor powder.

[0020] Take 0.75g of the prepared precursor powder and place it in an agate mortar, grind it for half an hour to prevent small particle products; add an appropriate amount of 5% PVA solution for grinding and granulation; then add the granulation product into a stainless steel tablet mold, and Compress with 4MPa pressure for 2min, and reversely press with 8MPa pressure for 2min to make a circular sheet with a diameter of about 12mm and a thickness o...

Embodiment 2

[0022] According to La 2 o 3 、MoO 3 The molar ratio between CuO and CuO is 1:1.6:0.4 Weigh the material, use absolute ethanol as the medium, mix the material into the mortar, use KEQ-D-P all-round planetary ball mill to grind for 2 hours, and the fineness is controlled at 10μm The following; then transfer the material to a crucible, put it in a muffle furnace, and calcine in air for 10 hours at a calcination temperature of 950°C; after calcination, take it out and grind it sufficiently to finally obtain a solid precursor powder.

[0023] Take 1.0 g of the prepared precursor powder and place it in an agate mortar, grind it for half an hour to prevent small particle products; add an appropriate amount of 5% PVA solution for grinding and granulation; then add the granulation product into a stainless steel tablet mold, and Compress with 4MPa pressure for 2min, and reversely press with 8MPa pressure for 2min to make a circular sheet with a diameter of about 12mm and a thickness of ...

Embodiment 3

[0025] According to La 2 o 3 、MoO 3 The molar ratio between CuO and CuO is 1:1.4:0.6 Weigh the material, use absolute ethanol as the medium, mix the material into the mortar, use KEQ-D-P all-round planetary ball mill to grind for 4 hours, and the fineness is controlled at 10μm The following; then transfer the material to a crucible, put it in a muffle furnace, and calcine in air for 10 hours at a calcination temperature of 950°C; after calcination, take it out and grind it sufficiently to finally obtain a solid precursor powder.

[0026] Take 0.5g of the prepared precursor powder and place it in an agate mortar, grind it for half an hour to prevent small particle products; add an appropriate amount of 5% PVA solution for grinding and granulation; then add the granulation product into a stainless steel tablet mold, and Compress with 4MPa pressure for 2min, and reversely press with 8MPa pressure for 2min to make a circular sheet with a diameter of about 12mm and a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com