Wormwood toothpaste

A technology of wormwood and toothpaste, applied in the fields of dentistry, medical science, digestive system, etc., can solve the problems of bacterial overgrowth, harmfulness to human body, etc., and achieve the effects of enhanced lubricity, low cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

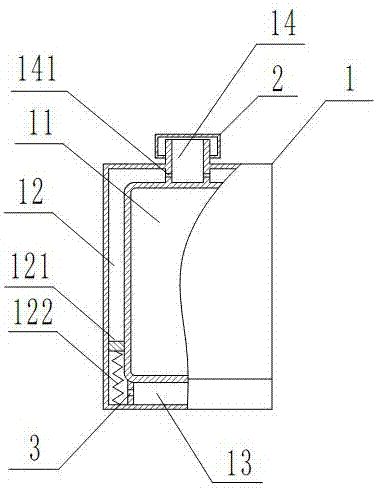

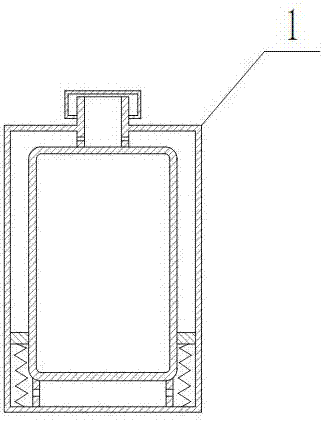

Image

Examples

Embodiment 1

[0031] The paste includes the following components in mass percentage, 30% hydrated silicic acid, 28% sorbitol, 2% glycerin, 1% sodium lauryl sulfate, 1% xanthan gum, 0.5% menthol, 0.1% xylitol, benzene Formic acid 0%, add pure water to 100%. Note that the moisturizer here can be a mixture of one or more moisturizers, as long as the total proportion is 20% to 30%.

[0032] Step 1, making paste: mix binder, surfactant, water, fragrance, and moisturizer evenly, and then send it into a vacuum paste tank; mix friction agent, thickener, and sweetener evenly and sprinkle it into Put it in the paste tank and stir, and finally add the preservative and continue to stir to make the paste;

[0033] Step 2, making the wormwood coating: Grinding the selected wormwood and putting it into a pot with a mass ratio of 1:4 of wormwood and water to form a wormwood juice. The water temperature in the pot is 90 ℃ ~ 100 ℃, after the wormwood juice is boiled and halved, add staghorn pectin, potassi...

Embodiment 2

[0036] The difference between this example and Example 1 is that the paste includes the following components by mass percentage, 40% hydrated silicic acid, 18% sorbitol, 2% glycerin, 2% sodium lauryl sulfate, and 2% xanthan gum , menthol 1%, xylitol 0.3%, benzoic acid 0.5%, add pure water to 100%.

[0037] Step 2, making the wormwood coating: Grind the selected wormwood, put it into a pot and boil it to form wormwood juice, the water temperature in the pot is 90°C-100°C, after boiling the wormwood juice Add staghorn pectin, potassium sorbate, wormwood essential oil and peppermint oil halfway, and cool the prepared wormwood coating to obtain a viscous wormwood coating. Description: The composition of the above-mentioned wormwood coating is calculated by mass percentage, 40% of wormwood juice, 3% of staghorn pectin, 0.5% of potassium sorbate, 5% of peppermint oil, and 100% of wormwood essential oil.

Embodiment 3

[0039] The difference between this example and Example 1 is that the paste includes the following components in mass percentage, 55% hydrated silicic acid, 20% sorbitol, 3% glycerin, 3% sodium lauryl sulfate, and 2% xanthan gum , menthol 1%, xylitol 0.3%, benzoic acid 1%, add pure water to 100%.

[0040] Step 2, making the wormwood coating: Grind the selected wormwood, put it into a pot and boil it to form wormwood juice, the water temperature in the pot is 90°C-100°C, after boiling the wormwood juice Add staghorn pectin, potassium sorbate, wormwood essential oil and peppermint oil halfway, and cool the prepared wormwood coating to obtain a viscous wormwood coating. Description: The composition of the above-mentioned wormwood coating is calculated by mass percentage, 40% of wormwood juice, 3% of staghorn pectin, 0.5% of potassium sorbate, 10% of peppermint oil, and 100% of wormwood essential oil.

[0041] Specific use: when using the wormwood toothpaste during the day, squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com