Epoxy modified acrylic resin and preparation method thereof

An acrylic resin, epoxy modification technology, applied in the direction of coating, etc., can solve the problems of poor control of epoxy resin ring opening, unstable synthetic resin process, easy gelation, etc., to achieve convenient production, good resistance Chemical, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

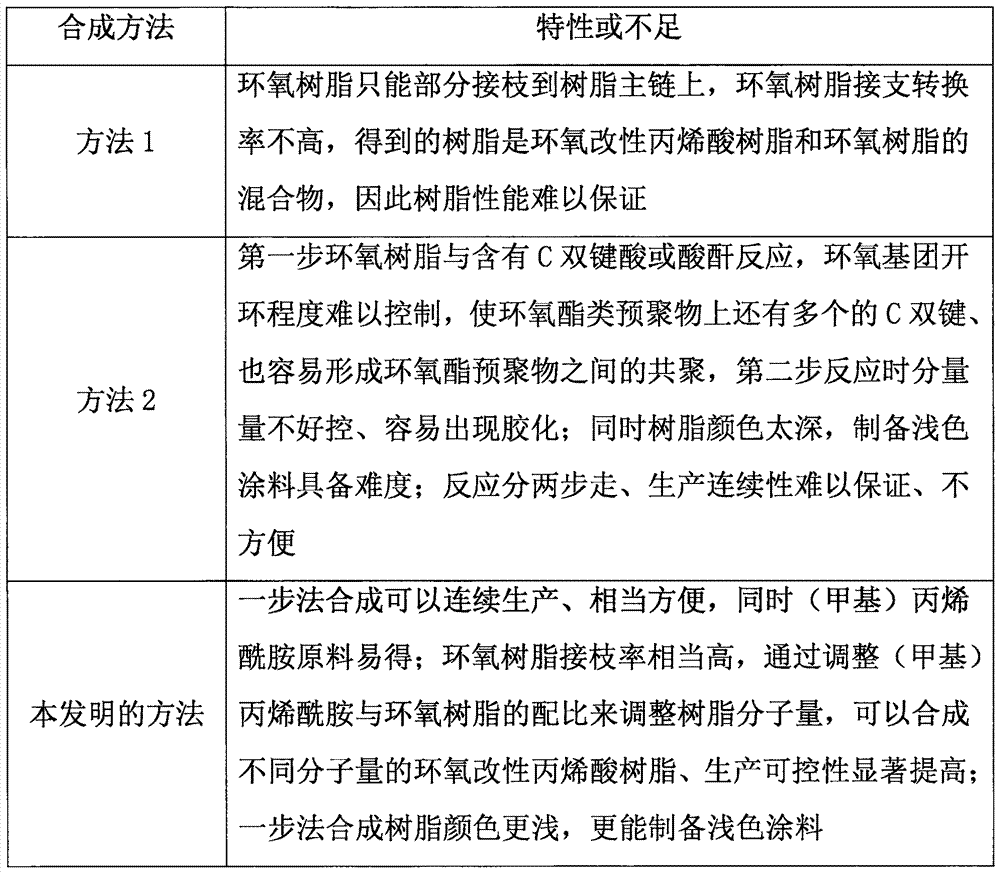

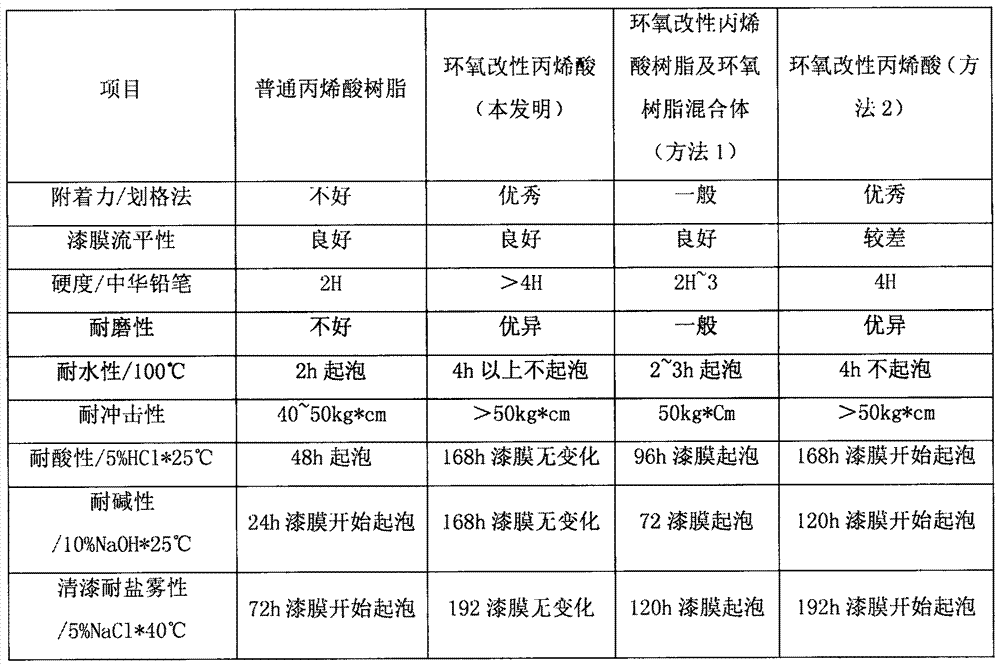

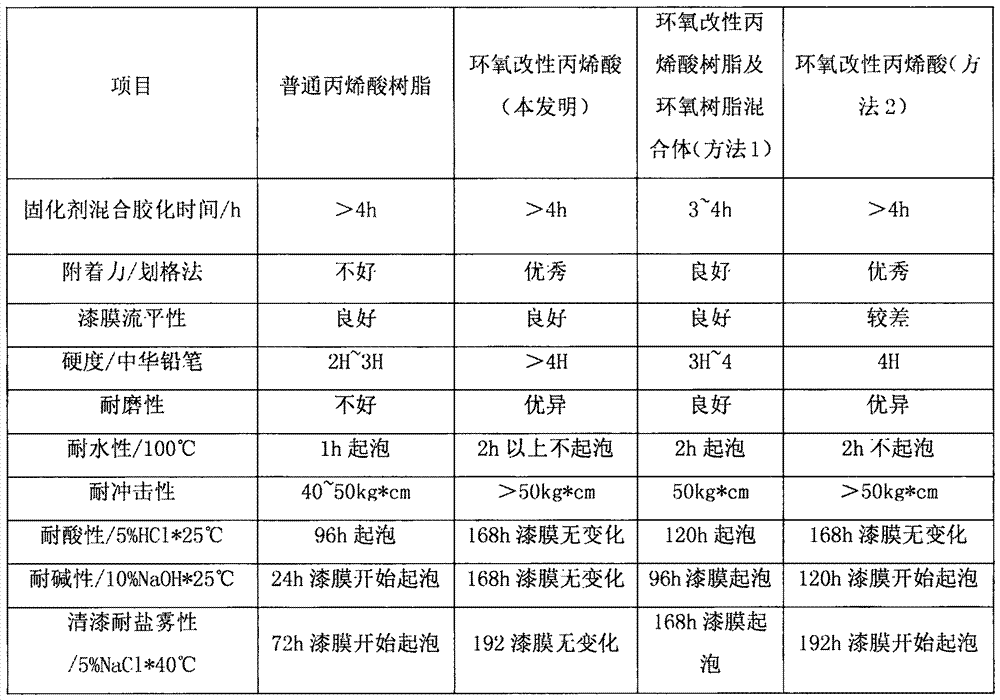

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An epoxy-modified acrylic resin provided in this embodiment includes raw material A component and a solvent based on 50% of the solidified portion of raw material A component, wherein the ratio of raw material A component is as follows in parts by weight: 25-28 parts of methyl acrylate; 18-20 parts of styrene; 28-32 parts of butyl (meth)acrylate; 18-22 parts of hydroxy (meth)acrylate; 1-3 parts of amine (meth)acrylate ; 1.5-2 parts of initiator, 6-10 parts of bisphenol A epoxy resin and 5-10 parts of (meth)acrylamide; the solvent is calculated according to the following weight percentages: xylene 80-82%, propylene glycol methyl ether Acetate 18-20%.

[0023] Preferably, the initiator is 3,5,5-trimethylhexanoic acid tert-butyl peroxide, peroxy-2-ethylhexanoic acid tert-butyl ester, peroxybenzoic acid tert-butyl ester, benzyl peroxide One or more of acyl, di-tert-butyl peroxide, di-tert-amyl peroxide, and dicumyl peroxide. In this embodiment, the initiators are tert-but...

Embodiment 2

[0031] An epoxy-modified acrylic resin provided in this embodiment includes raw material A component and a solvent based on 50% of the solidified portion of raw material A component, wherein the ratio of raw material A component is as follows in parts by weight: 28 parts of methyl acrylate; 20 parts of styrene; 32 parts of butyl (meth)acrylate; 22 parts of hydroxy (meth)acrylate; 3 parts of amine (meth)acrylic acid; 10 parts of epoxy resin and 10 parts of (meth)acrylamide; the solvent is calculated according to the following weight percentages: xylene 82%, propylene glycol methyl ether acetate 18%.

[0032] This embodiment also discloses a preparation method of epoxy-modified acrylic resin, which specifically includes the following steps:

[0033] (a) First put the bisphenol A type epoxy resin and xylene in the formula raw materials into the reactor, feed N2 for protection, start the reactor and stir, so that the two are completely dissolved and the temperature is raised to 11...

Embodiment 3

[0038]An epoxy-modified acrylic resin provided in this embodiment includes raw material A component and a solvent based on 50% of the solidified portion of raw material A component, wherein the ratio of raw material A component is as follows in parts by weight: 26-28 parts of methyl acrylate; 19-20 parts of styrene; 30-32 parts of butyl (meth)acrylate; 20-22 parts of hydroxy (meth)acrylate; 2-3 parts of amine (meth)acrylate ; 1.8-2 parts of initiator, 8-10 parts of bisphenol A epoxy resin and 8-10 parts of (meth)acrylamide; the solvent is calculated according to the following weight percentages: xylene 81-82%, propylene glycol methyl ether Acetate 18-19%.

[0039] This embodiment also discloses a preparation method of epoxy-modified acrylic resin, which specifically includes the following steps:

[0040] (a) First put the bisphenol A type epoxy resin and xylene in the formula raw materials into the reactor, feed N2 for protection, start the reactor and stir, so that the two a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com