Nylon 6/polyphenyl ether composition and preparation method thereof

A technology of polyphenylene ether and composition, which is applied in the field of nylon 6/polyphenylene ether composition and its preparation, can solve the problems of easy deliquescence, unclean cleaning, and reduce the corrosion of chlorides to equipment, and achieve a small size of the dispersed phase , Excellent mechanical properties, and the effect of reducing the viscosity difference of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

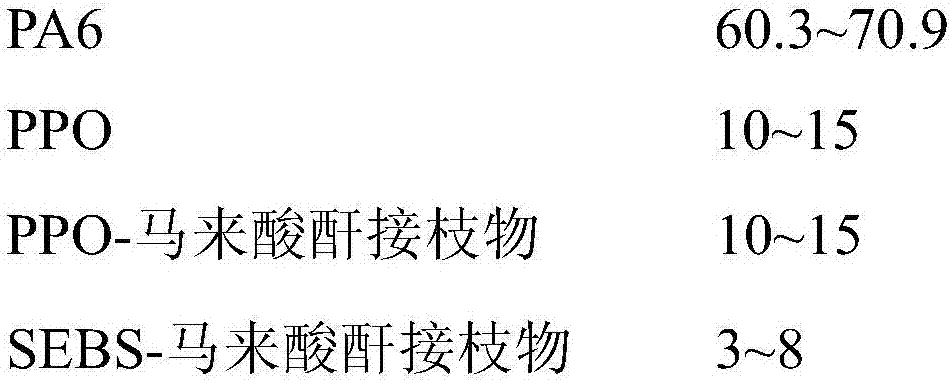

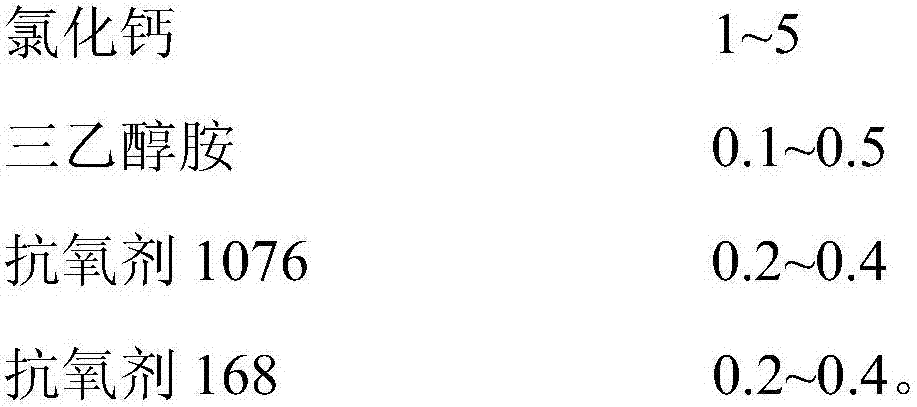

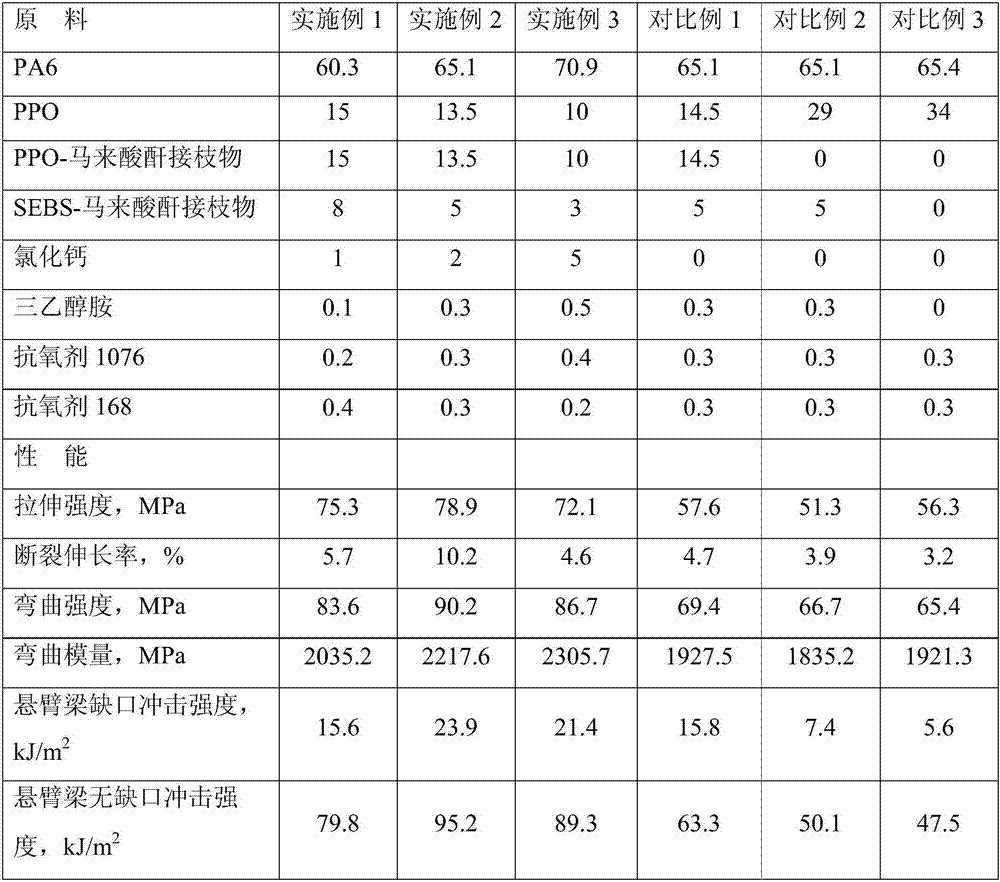

[0034] (1) Premixing: 60.3 parts by mass of PA6, 15 parts by mass of PPO, 15 parts by mass of PPO-maleic anhydride grafts, 8 parts by mass of SEBS-maleic anhydride grafts, 1 part by mass of calcium chloride, 0.1 parts by mass of Parts of triethanolamine, 0.2 parts by mass of antioxidant 1076 and 0.4 parts by mass of antioxidant 168 were sequentially added to a high-speed mixer for pre-mixing. The mixing temperature was 45°C, the rotational speed was 450 rpm, and the mixing time was 6 minutes.

[0035] (2) Extrusion granulation: Add the above-mentioned premixed materials from the feeder to a twin-screw extruder (screw diameter 25mm, aspect ratio 40), melt extrusion granulation, and obtain nylon 6 / polyphenylene ether combination. The process conditions are set as follows: the screw speed is 180 rpm; the feeder speed is 30 rpm; the temperature of each section of the extruder is 200-250°C.

[0036] The dried nylon 6 / polyphenylene ether composition was injected into a standard sam...

Embodiment 2

[0038] (1) Premixing: 65.1 parts by mass of PA6, 13.5 parts by mass of PPO, 13.5 parts by mass of PPO-maleic anhydride grafts, 5 parts by mass of SEBS-maleic anhydride grafts, 2 parts by mass of calcium chloride, 0.3 parts by mass of Parts of triethanolamine, 0.3 parts by mass of antioxidant 1076 and 0.3 parts by mass of antioxidant 168 were sequentially added to a high-speed mixer for pre-mixing. The mixing temperature was 50°C, the rotational speed was 500 rpm, and the mixing time was 4 minutes.

[0039](2) Extrusion granulation: Add the above-mentioned premixed materials from the feeder to a twin-screw extruder (screw diameter 25mm, aspect ratio 40), melt extrusion granulation, and obtain nylon 6 / polyphenylene ether combination. The process conditions are set as follows: the screw speed is 200 rpm; the feeder speed is 40 rpm; the temperature of each section of the extruder is 200-250°C.

[0040] The dried nylon 6 / polyphenylene ether composition was injected into a standard...

Embodiment 3

[0042] (1) Premixing: 70.9 parts by mass of PA6, 10 parts by mass of PPO, 10 parts by mass of PPO-maleic anhydride grafts, 3 parts by mass of SEBS-maleic anhydride grafts, 5 parts by mass of calcium chloride, 0.5 parts by mass of Parts of triethanolamine, 0.4 parts by mass of antioxidant 1076 and 0.2 parts by mass of antioxidant 168 were sequentially added to a high-speed mixer for pre-mixing. The mixing temperature was 35°C, the rotational speed was 300 rpm, and the mixing time was 6 minutes.

[0043] (2) Extrusion granulation: Add the above-mentioned premixed materials from the feeder to a twin-screw extruder (screw diameter 25mm, aspect ratio 40), melt extrusion granulation, and obtain nylon 6 / polyphenylene ether combination. The process conditions are set as follows: the screw speed is 220 rpm; the feeder speed is 25 rpm; the temperature of each section of the extruder is 200-250°C.

[0044] The dried nylon 6 / polyphenylene ether composition was injected into a standard sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com