Method for aerobically producing hydrogen by respiration interaction of aerobic hydrogen producing bacteria and aerobic bacteria

一种氢气、菌粉的技术,应用在基于微生物的方法、生物化学设备和方法、细菌等方向,能够解决不利生物制氢扩大化、条件苛刻、操作繁琐等问题,达到减轻底物竞争、提高产率、纯度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

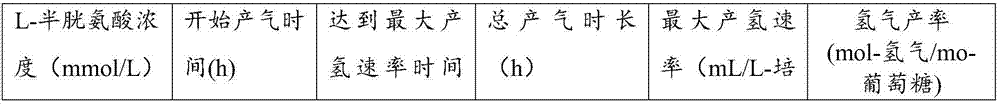

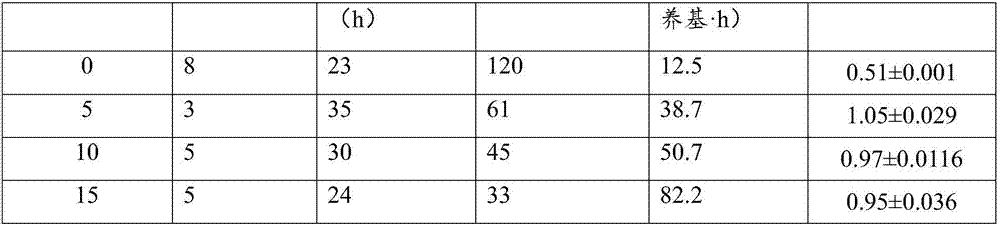

[0032] Example 1: Co-culture hydrogen production with sucrose as carbon source

[0033] This embodiment provides a method for aerobic hydrogen production using the respiration interaction between Ethanoligenens harbinense YUAN-3 and Pseudomonas aeruginosa PAO1, which is implemented in the following steps:

[0034]1. Cultivate Harbin Ethanologenic Bacillus YUAN-3 by anaerobic culture method: Culture Harbin Ethanologenic Bacillus YUAN-3 with liquid medium A after high-temperature steam sterilization, and place the inoculated anaerobic bottle in a constant temperature shaker Cultivate with shaking at 35°C and 170rpm. After 40 hours, agglutinate and form white spherical bacterial micelles at the bottom of the culture bottle. Keep the supernatant clear, centrifuge at 8000 rpm for 5 minutes, and discard the supernatant;

[0035] 2. Cultivate Pseudomonas aeruginosa PAO1 by aerobic culture method: use liquid medium B sterilized by high temperature steam to cultivate Pseudomonas aerugi...

Embodiment 2

[0049] Example 2: Co-culture hydrogen production with lactose as carbon source

[0050] This embodiment provides a method for aerobic hydrogen production using the respiration interaction between Ethanoligenens harbinense YUAN-3 and Pseudomonas aeruginosa PAO1, which is implemented in the following steps:

[0051] 1. Cultivate Harbin Ethanologenic Bacillus YUAN-3 by anaerobic culture method: Culture Harbin Ethanologenic Bacillus YUAN-3 with liquid medium A after high-temperature steam sterilization, and place the inoculated anaerobic bottle in a constant temperature shaker Cultivate with shaking at 35°C and 170rpm. After 40 hours, agglutinate and form white pellets at the bottom of the culture bottle. The supernatant remains clear. Centrifuge at 8000 rpm for 5 minutes and discard the supernatant;

[0052] 2. Cultivate Pseudomonas aeruginosa PAO1 by aerobic culture method: use liquid medium B sterilized by high temperature steam to cultivate Pseudomonas aeruginosa, and place th...

Embodiment 3

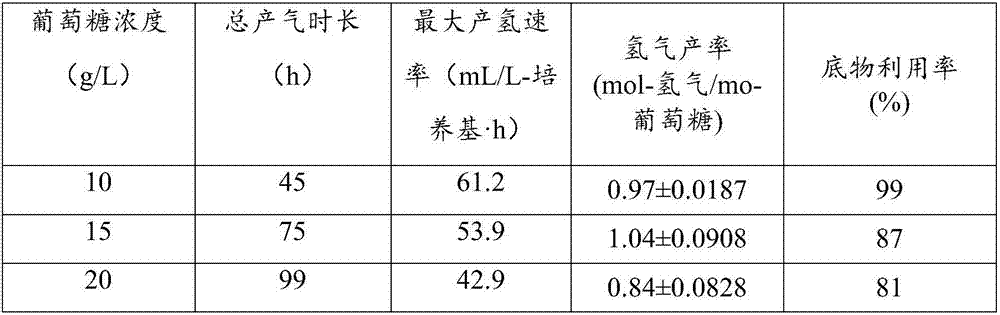

[0066] Example 3: Hydrogen production by fermentation with glucose as substrate

[0067] This embodiment provides a method for aerobic hydrogen production using the respiration interaction between Ethanoligenens harbinense YUAN-3 and Pseudomonas aeruginosa PAO1, which is implemented in the following steps:

[0068] 1. Cultivate Harbin Ethanologenic Bacillus YUAN-3 by anaerobic culture method: Culture Harbin Ethanologenic Bacillus YUAN-3 with liquid medium A after high-temperature steam sterilization, and place the inoculated anaerobic bottle in a constant temperature shaker Cultivate with shaking at 35°C and 170rpm. After 40 hours, agglutinate and form white pellets at the bottom of the culture bottle. The supernatant remains clear. Centrifuge at 8000 rpm for 5 minutes and discard the supernatant;

[0069] 2. Cultivate Pseudomonas aeruginosa PAO1 by aerobic culture method: use liquid medium B sterilized by high temperature steam to cultivate Pseudomonas aeruginosa, and place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com