Preparation method of broadly distributed multifunctional polysaccharide-based ligand metal complex tanning agent

A technology of metal complexes and multifunctional groups, which is applied in the field of leather and fur tanning preparations, can solve the problems of reduced oxidation, low content of carboxyl and aldehyde groups, and high reaction temperature, so as to reduce viscosity, surface tension and molecular weight Wide distribution, the effect of improving the tanning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

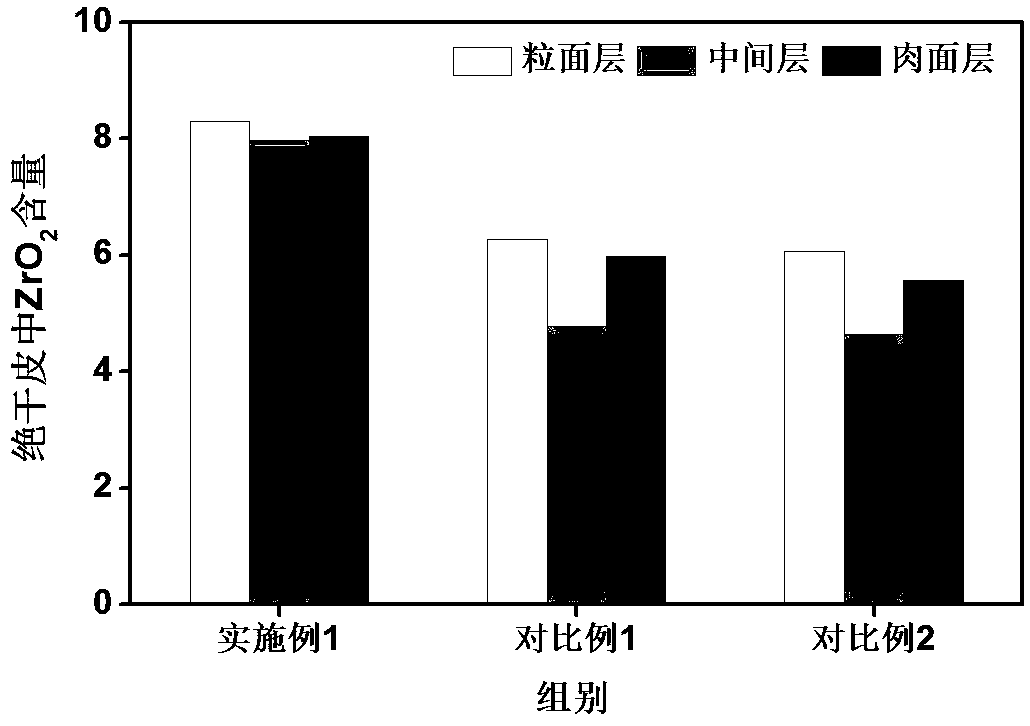

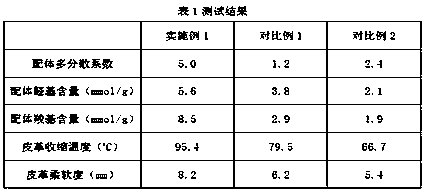

Embodiment 1

[0025] In parts by weight, 30 parts of starch, 100 parts of water and 0.015 parts of copper sulfate are placed in a reactor, 18 parts of hydrogen peroxide are added dropwise, and the reaction is carried out by one-step oxidation at a temperature of 120 °C and a pressure of 0.2 MPa for 2 h to obtain broad Distributed liquid multifunctional starch-based ligands; after adjusting the pH of the ligands to 2 with NaOH solution, add 90 parts of zirconium sulfate, and stir for 12 hours to obtain a wide-distributed multifunctional starch-based ligand zirconium complex tanning agent.

[0026] Place the pickled hides obtained by the conventional process in the drum, add 200 wt% pickling solution and 25 wt% complex tanning agent (in terms of solid content) based on the weight of the pickled hides, turn 3 After 2 hours, the alkali was raised with magnesium oxide to pH 3.0, and then the alkali was raised with sodium bicarbonate to pH 3.8, the temperature was adjusted to 40°C, and the process...

Embodiment 2

[0037] In parts by weight, put 5 parts of sodium alginate, 100 parts of water and 0.00025 parts of ferrous sulfate in the reactor, add 2 parts of hydrogen peroxide dropwise, and conduct a one-step oxidation reaction at a temperature of 140°C and a pressure of 0.4 MPa for 0.5 h , to obtain a wide distribution of liquid multifunctional sodium alginate-based ligands; after adjusting the pH of the ligand to 4 with NaOH solution, add 12 parts of aluminum sulfate, and stir for 24 h to obtain a wide distribution of multifunctional sodium alginate-based ligands aluminum Complex tanning agent.

[0038] The pickling fur obtained by the conventional process is placed in a drum, and the pickling solution that is 500 wt% based on the weight of the pickling fur and the complex tanning agent of 26 g / L in terms of the volume of water added (in solids) are added. content meter), after turning for 6 hours, the alkali was extracted with magnesium oxide to pH 3.0, then the alkali was extracted wi...

Embodiment 3

[0041] In parts by weight, 50 parts of sodium carboxymethyl starch, 100 parts of water and 0.05 part of ferric sulfate are placed in the reactor, and 50 parts of hydrogen peroxide are added dropwise, at a temperature of 160 °C and a pressure of 0.6 MPa, the oxidation reaction is carried out in one step 4 h, to obtain a wide distribution of liquid multifunctional sodium carboxymethyl starch ligand; after adjusting the pH of the ligand to 4 with NaOH solution, add 90 parts of titanium sulfate, and directly obtain a wide distribution of multifunctional sodium carboxymethyl starch ligand without stirring Titanium complex tanning agent.

[0042] Place the pickled hides obtained by the conventional process in the drum, add 80 wt% pickling solution and 5 wt% complex tanning agent (in terms of solid content) based on the weight of the pickled hides, turn 2 After 2 hours, the alkali was extracted with magnesium oxide to pH 3.0, and then the alkali was extracted with sodium bicarbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com