Method for preparing lithium-ion battery anode material through iron-containing solid waste from electroflocculation printing-dyeing wastewater

A lithium-ion battery, printing and dyeing wastewater technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problem of high processing cost, achieve the effect of good performance and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

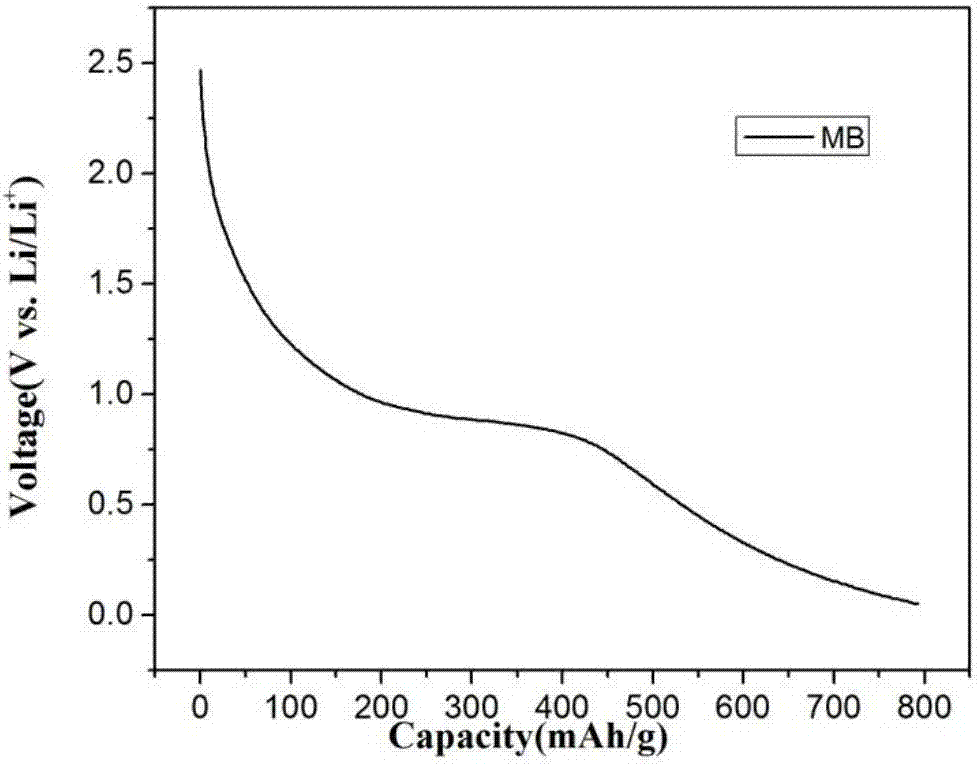

Embodiment 1

[0038] Wastewater comes from a paper dyeing factory that dyes a batch of paper. The organic dye used in the dyeing process is methylene blue. They are dyed. Take 2 tons of (absolutely dry) wood pulp and put it in a container, add water according to the pulp concentration of 1%, disperse until there are no lumps, adjust the appropriate pH value, heat at a specific temperature, and stir with a stirrer at the same time, then pass Into 0.5% (dry) methylene blue solution. Add 0.5% (absolutely dry) NaCl as a dyeing aid, and make paper after a period of heat balance (contact time). The drying temperature is 92°C and the drying time is 5 minutes. After copying the paper, the remaining liquid is exactly the waste water of the present invention.

[0039] The iron-containing sludge produced by electrocoagulation is used to prepare lithium-ion battery negative electrode materials and methods, comprising the following steps:

[0040] (1) Preparation of solid waste iron sludge: Measure 2...

Embodiment 2

[0045] The waste water is discharged from a textile printing and dyeing company after dyeing a batch of textiles. The organic dye used in the dyeing process is Rhodamine-B. To stain. The process is to put the bleached cotton cloth into a bathtub with a liquor ratio of 20:1, and the components of the dye solution are 1.5g / L Rhodamine-B, 2.5g / L Pingpingjia O-25, and 2.5g / L Swire Oil. Stir and heat the cotton cloth and dye to 60°C, add salt, and maintain for 20 minutes, add sodium carbonate, keep the temperature for 20-40 minutes, cool down, and the remaining dye liquor is the printing and dyeing wastewater described in the present invention.

[0046] The iron-containing sludge produced by electrocoagulation is used to prepare lithium-ion battery negative electrode materials and methods, comprising the following steps:

[0047] (1) Preparation of solid waste iron sludge: Measure 200mL of filtered waste water containing rhodamine-B3.13mmol / L after dyeing a batch of textiles by a ...

Embodiment 3

[0052] The waste water is discharged from a plastic coloring company after coloring the raw materials of toys. The organic dye used in the dyeing process is lemon yellow. / L lemon yellow dye solution is sprayed on the printing plate, the spray gun pressure is 0.2MPa, the printing plate is removed and dried at 60 degrees. The dye solution dripped on the printing plate during the spraying process is exactly the waste water described in the present invention.

[0053] The iron-containing sludge produced by electrocoagulation is used to prepare lithium-ion battery negative electrode materials and methods, comprising the following steps:

[0054] (1) Preparation of solid waste iron sludge: Measure 200mL of filtered waste water containing tartrazine 2.80mmol / L after a certain plastic coloring company colored the toy raw materials, add it to a 250mL beaker together with 10g of sodium sulfate, stir, and mix into solution. Turn on the DC stabilized voltage and current power supply, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume usage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com