Monodisperse porous hydroxyapatite microsphere, preparation method and application of microsphere

A hydroxyapatite and monodisperse technology, which is applied in chemical instruments and methods, phosphorus compounds, and other chemical processes, can solve the problems of complex preparation process, uneven particle size distribution of microspheres, and low yield, and achieve the goal of preparing The effect of simple process, flexible and controllable pore size, and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

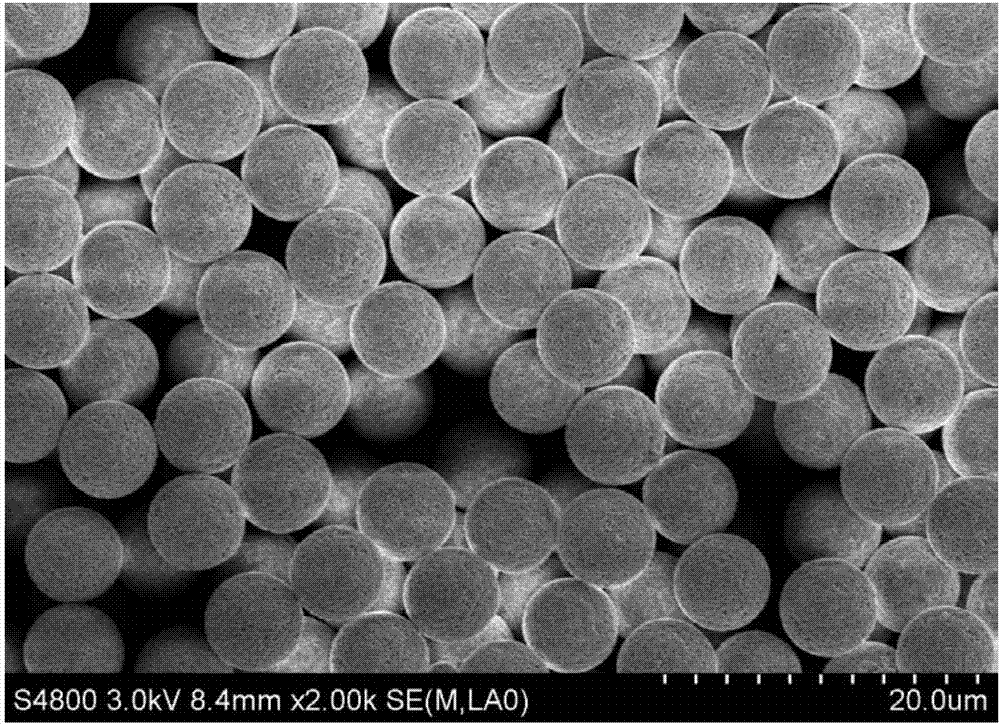

[0029] A kind of monodisperse porous hydroxyapatite microsphere, comprises the following steps:

[0030] (1) preparing porous polymer microspheres with a particle size of 5 μm and CV=3.2%;

[0031] (2) 100 grams of porous polymer microspheres were placed in 120 grams of water, and ammonia water was added while stirring, so that the system was adjusted to pH=10-11 to obtain solution A;

[0032] (3) Weighing Ca(NO 3 ) 2 .4H 2 O and (NH 4 ) 2 HPO 4 Dissolve in 80 grams of water, according to the ratio Ca: P = 1.67, to obtain solution B;

[0033] (4) Add B dropwise to A, and continue to react for 24 hours after the dropwise addition to obtain solution C;

[0034] (5) filter C, obtain polymer-hydroxyapatite composite microspheres after washing and drying;

[0035] (6) The polymer-hydroxyapatite composite microspheres are heated to 650°C and calcined for 6 hours to remove the organic polymers and form porous hydroxyapatite microspheres.

[0036] The porous polymer microsphe...

Embodiment 2

[0039] A kind of monodisperse porous hydroxyapatite microsphere, comprises the following steps:

[0040] (1) preparing porous polymer microspheres with a particle size of 2 μm and CV=3.1%;

[0041] (2) 50 grams of porous polymer microspheres were placed in 70 grams of water, and ammonia water was added while stirring, so that the system was adjusted to pH=10-11 to obtain solution A;

[0042] (3) Weighing Ca(NO 3 ) 2 .4H 2 O and (NH 4 ) 2 HPO 4 Dissolve in 50 grams of water, according to the ratio Ca: P = 2.37, to obtain solution B;

[0043] (4) Add solution B dropwise to solution A, and after the dropwise addition, continue to react for 24 hours at 70-80° C. to obtain solution C;

[0044] (5) filter solution C, obtain polymer-hydroxyapatite composite microspheres after washing and drying;

[0045] (6) The polymer-hydroxyapatite composite microspheres are heated to 550° C. and calcined for 6 hours to remove the organic polymers and form porous hydroxyapatite microsphere...

Embodiment 3

[0049] A kind of monodisperse porous hydroxyapatite microsphere, comprises the following steps:

[0050] (1) preparing porous polymer microspheres with a particle size of 500 μm and CV=3.2%;

[0051] (2) 100 grams of porous polymer microspheres were placed in 120 grams of water, and ammonia water was added while stirring, so that the system was adjusted to pH=10-11 to obtain solution A;

[0052] (3) Weighing Ca(NO 3 ) 2 .4H 2 O and (NH 4 ) 2 HPO 4 Dissolve in 80 grams of water, according to the ratio Ca: P = 1.67, to obtain solution B;

[0053] (4) Add solution B dropwise to solution A, and continue to react at 50° C. for 24 hours after the dropwise addition to obtain solution C;

[0054] (5) filter solution C, obtain polymer-hydroxyapatite composite microspheres after washing and drying;

[0055](6) The polymer-hydroxyapatite composite microspheres were heated to 800° C. for 6 hours and calcined to remove the organic polymers, resulting in porous hydroxyapatite micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com