X-band resistive film-type high-temperature-resistant metamaterial-containing wave absorber

A technology of metamaterials and wave absorbers, applied in electrical components, antennas, etc., can solve the problems of narrow frequency band, insufficient absorption capacity, increase the weight of weapons and equipment, etc., and achieve the effect of strong wave absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

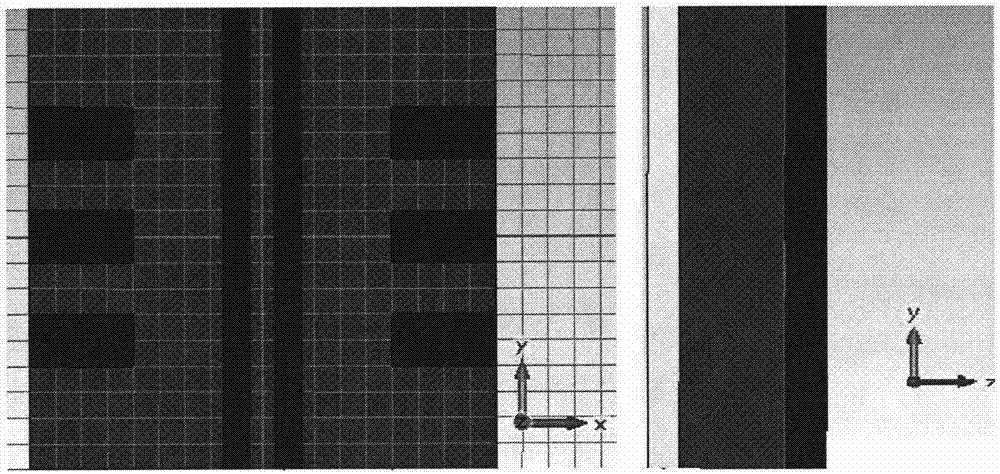

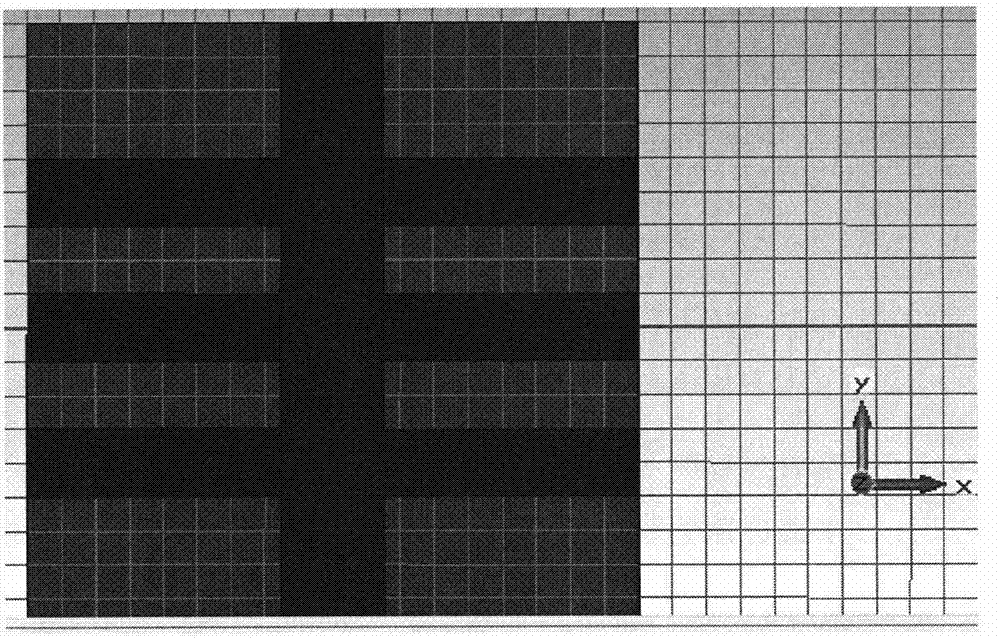

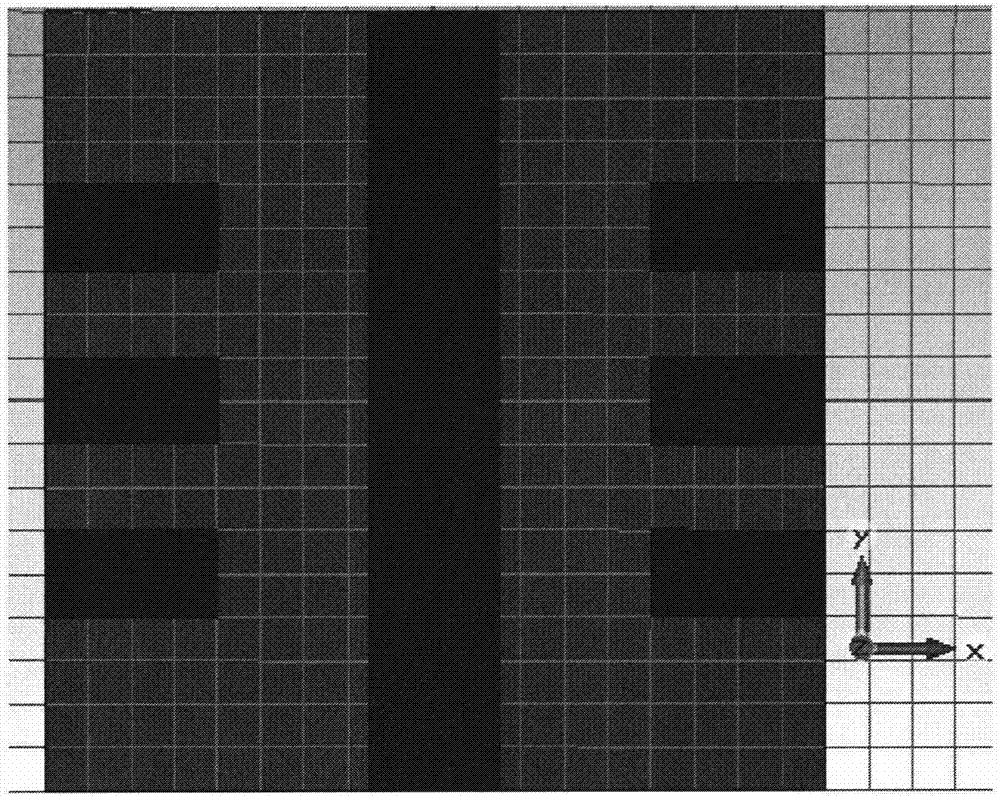

Image

Examples

example 1

[0018] Weigh 346.4g of lanthanum nitrate, 42.326g of strontium nitrate, 357.9g of 50% manganese nitrate solution, 230.57g of citric acid, and 297.936g of ethylene glycol, and set aside. La was obtained by sol-gel method combined with heat treatment x Sr 1-x MnO 3 Black fluffy block. Put the black fluffy block into an agate mortar and grind it thoroughly to obtain strontium lanthanum manganate conductive ceramic powder. Put the black fluffy block into an agate mortar and grind it thoroughly to obtain strontium lanthanum manganate conductive ceramic powder. Take 97g of terpineol and 3g of ethyl cellulose, fully heat and stir at 100°C for 7h, so that the ethyl cellulose is completely dissolved in terpineol. The above-mentioned organic carrier and strontium lanthanum manganate ceramic powder were weighed according to the mass ratio of 7:3, and placed in an agate mortar, fully ground and stirred; put the agate mortar into an ultrasonic disperser, so that the powder and organic ...

example 2

[0020] Weigh lanthanum nitrate 303.1g, strontium nitrate 84.652g, 50% manganese nitrate solution 357.9g, citric acid 230.57g, ethylene glycol 297.936g, set aside. La was obtained by sol-gel method combined with heat treatment x Sr 1-x MnO 3 Black fluffy block. Put the black fluffy block into an agate mortar and grind it thoroughly to obtain strontium lanthanum manganate conductive ceramic powder. Put the black fluffy block into an agate mortar and grind it thoroughly to obtain strontium lanthanum manganate conductive ceramic powder. Take 97g of terpineol and 3g of ethyl cellulose, fully heat and stir at 100°C for 7h, so that the ethyl cellulose is completely dissolved in terpineol. The above-mentioned organic carrier and strontium lanthanum manganate ceramic powder were weighed according to the mass ratio of 7:3, and placed in an agate mortar, fully ground and stirred; put the agate mortar into an ultrasonic disperser, so that the powder and organic The carrier is mixed e...

example 3

[0022] Weigh lanthanum nitrate 259.8g, strontium nitrate 63.489g, 50% manganese nitrate solution 357.9g, citric acid 230.57g, ethylene glycol 297.936g, set aside. La was obtained by sol-gel method combined with heat treatment x Sr 1-x MnO 3 Black fluffy block. Put the black fluffy block into an agate mortar and grind it thoroughly to obtain strontium lanthanum manganate conductive ceramic powder. Put the black fluffy block into an agate mortar and grind it thoroughly to obtain strontium lanthanum manganate conductive ceramic powder. Take 97g of terpineol and 3g of ethyl cellulose, fully heat and stir at 100°C for 7h, so that the ethyl cellulose is completely dissolved in terpineol. The above-mentioned organic carrier and strontium lanthanum manganate ceramic powder were weighed according to the mass ratio of 7:3, and placed in an agate mortar, fully ground and stirred; put the agate mortar into an ultrasonic disperser, so that the powder and organic The carrier is mixed e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com