Preparation method of carbon-base efficient organic-inorganic compound fertilizer

A compound fertilizer and high-efficiency technology, applied in the direction of inorganic fertilizers, nitrogen fertilizers, potassium fertilizers, etc., can solve problems such as difficult to control nutrient balance, unfavorable growth of agricultural plants, and too late for crops to absorb, so as to improve the ability of soil to retain water and fertilizer, and improve fertilizer utilization rate, the effect of promoting crop growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

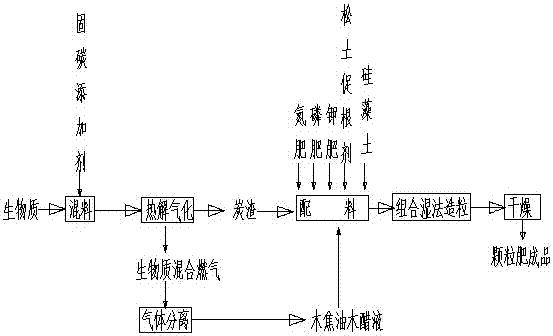

[0016] Such as figure 1 As shown, the preparation method of carbon-based high-efficiency organic-inorganic compound fertilizer in this embodiment includes the following steps: 1) Mixing materials: adding carbon-fixing additives to the biomass raw materials combined with straw and arbor, and the quality of carbon-fixing additives and biomass raw materials The ratio is 5%, and the carbon fixation additive includes 50% diatomite, 20% calcium oxide and 30% magnesium ore powder, all of which are percentages by mass, and the particle sizes of the three components are all 60 mesh; 2) heat Degasification: Biomass raw materials and carbon-fixing additives are sent into the gasifier, pyrolyzed and gasified under the micro-oxygen conditions of 600°C and air equivalence ratio between 0.18, and the biomass mixed gas containing some impurities is obtained. Discharge the charcoal residue in the furnace; 3) Gas separation: the biomass mixed gas is removed from the wood tar and wood vinegar th...

Embodiment 2

[0018] The preparation method of carbon-based high-efficiency organic-inorganic compound fertilizer in this embodiment includes the following steps: 1) Mixing materials: adding a carbon-fixing additive to the biomass raw material combined with straw and shrubs, and the mass ratio of the carbon-fixing additive to the biomass raw material is 8 %, in which the carbon fixation additive contains 60% diatomite, 25% calcium oxide and 15% magnesium ore powder, all of which are percentages by mass, and the particle sizes of the three components are all 80 mesh; 2) Pyrolysis and gasification : Biomass raw materials and carbon-fixing additives are sent into the gasifier, pyrolyzed and gasified under the micro-oxygen conditions of 800°C and air equivalence ratio of 0.25, and the biomass mixed gas containing some impurities is obtained. 3) Gas separation: under the action of the induced draft fan, the biomass mixed gas will remove wood tar and wood vinegar through a sinking purifier to obta...

Embodiment 3

[0020]The preparation method of carbon-based high-efficiency organic-inorganic compound fertilizer in this embodiment includes the following steps: 1) Mixing materials: adding carbon-fixing additives to the biomass raw materials combined with straw, trees and shrubs, and the mass ratio of carbon-fixing additives to biomass raw materials The carbon fixation additive contains 53% diatomite, 30% calcium oxide and 17% magnesium ore powder, all of which are percentages by mass, and the particle sizes of the three components are all 70 mesh; 2) Pyrolysis Gasification: Biomass raw materials and carbon-fixing additives are sent into the gasifier, pyrolyzed and gasified under the micro-oxygen conditions of 700°C and air equivalence ratio between 0.21, and the biomass mixed gas containing some impurities is obtained. The carbon residue in the furnace is discharged; 3) Gas separation: under the action of the induced draft fan, the biomass mixed gas is removed from the wood tar and wood vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com