A kind of zinc heat stabilizer for PVC and its preparation method and application

A composite heat stabilizer and metal zinc technology, which is applied in the new type of zinc heat stabilizer for PVC and in the field of polyvinyl chloride processing, can solve the problems of poor stability of calcium-zinc composite stabilizers and achieve good performance. Long-term stable effect, less steps, whiteness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

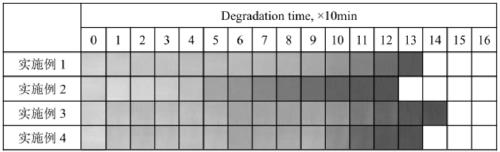

Embodiment 1~4

[0041]Put 11.2g of 3-amino-1,2,4-triazole and 65.7mL of absolute ethanol in a three-necked flask, stir evenly for 1h, dissolve 5.3g of zinc acetate dihydrate in 40.0mL of absolute ethanol and slowly drop into In a three-neck flask, reflux reaction for 4 hours, when the reaction no longer produces precipitation, the reaction is over, then cooled to room temperature, filtered, the filter cake was washed with distilled water (200mL×3), put into a blast oven, and dried at 100°C. The product diacetic acid-bis(3-amino-1,2,4-triazole)zinc was obtained. The obtained diacetic acid-bis(3-amino-1,2,4-triazole) zinc and stearate, epoxidized soybean oil, dibenzoylmethane, pentaerythritol stearic acid monoester and stearin Acid, fed according to the formula ratio, stirred and mixed in a high-speed mixer, stirred and heated to 100°C, stirred at a speed of 50r / min, and stirred for 10 minutes to prepare the zinc-containing heat stabilizer of the present invention, the specific feeding of each ...

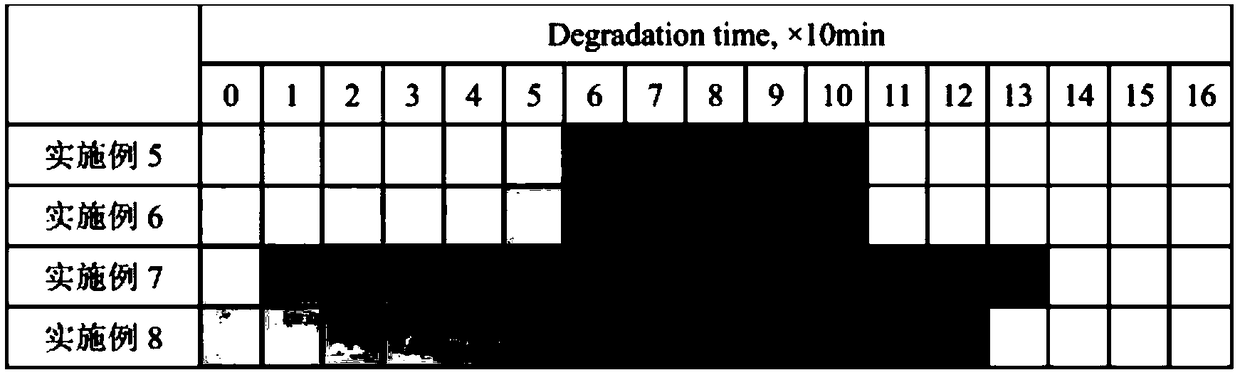

Embodiment 5~8

[0046] Put 33.2g of 3,5-diamino-1,2,4-triazole and 50.0mL of dehydrated ethanol in a three-necked flask, stir evenly for 1h, dissolve 10.6g of zinc sulfate heptahydrate in 21.2mL of dehydrated ethanol and slowly Drop into the three-necked flask, reflux reaction for 4h, when the reaction no longer produces precipitation, the reaction is over, then cooled to room temperature, filtered, the filter cake was washed with distilled water (200mL×3), put it into a blast oven, and heated at 100°C The product is dried at low temperature to obtain the product disulfuric acid-bis(3,5-diamino-1,2,4-triazole)zinc. Disulfuric acid-bis(3,5-diamino-1,2,4-triazole) zinc and zinc stearate, epoxidized soybean oil, dibenzoylmethane, pentaerythritol stearic acid monoester and stearic acid, feed intake according to the formula ratio, and stir and mix in a high-speed mixer, stir and be warmed up to 100°C, the stirring speed is 50r / min, and the zinc-containing heat stabilizer of the present invention i...

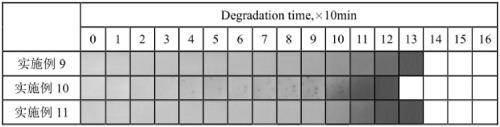

Embodiment 9-11

[0051] Put 34.0g of 4-amino-1,2,4-triazole and 40.0mL of absolute ethanol in a three-necked flask, stir evenly for 1h, dissolve 11.0g of zinc oxide in 29.7mL of absolute ethanol and slowly drop into the three-necked flask reflux reaction for 4 hours, when the reaction no longer produces precipitation, the reaction is complete, then cooled to room temperature, filtered, and the filter cake was washed with distilled water (200mL×3), placed in a blast oven, and dried at 100°C to obtain the product Dioxo-(4-amino-1,2,4-triazole)zinc. Dioxo-(4-amino-1,2,4-triazole) zinc and zinc stearate, epoxy sunflower oil, stearyl benzoylmethane, dipentaerythritol monostearate ( It is obtained by the reaction of dipentaerythritol and C12 long-chain fatty acid) and stearic acid, fed according to the formula ratio, stirred and mixed in a high-speed mixer, stirred and heated to 100°C, stirring speed 50r / min, and stirred for 10 minutes to obtain this product The zinc-containing heat stabilizer desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com