Biomass in-situ hydrogen supply liquefaction oil preparation method

A biomass and in-situ technology, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, etc., can solve the problems of environmental hazards, insufficient hydrogen supply efficiency, high cost, etc., to increase the calorific value and solve the problem of recycling problems, the effects of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

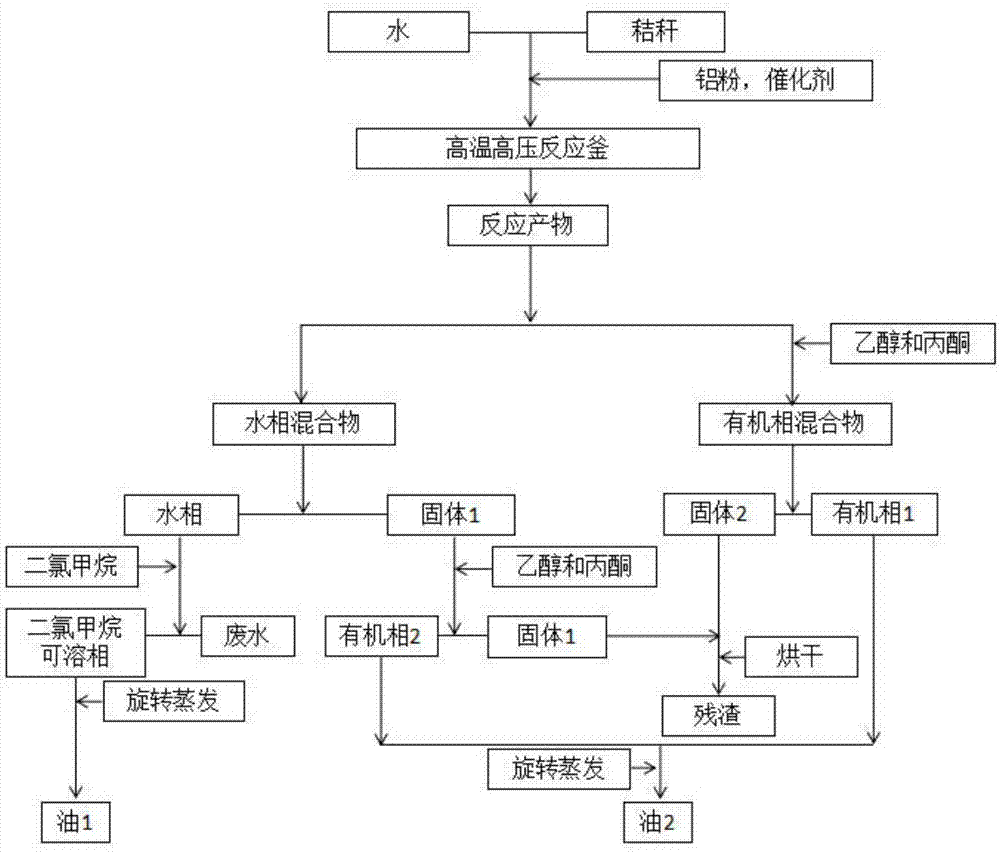

Embodiment 1

[0020] Add 15g of corn stalk powder, 0g of NiS-MoS, 0g of aluminum powder, and then add 150mL of deionized water, mix evenly and seal the reaction vessel; before heating up each experiment, use high-purity nitrogen (99.99%) to purge for 5min to remove air, magnetically stir The speed of the device is set to 100r / min and gradually increased to 300r / min; the temperature in the kettle is set to 370°C, and the reaction residence time is set to 60min; Determine its composition, and then open the reactor. Pour out the solid-liquid mixture in the kettle, and obtain the aqueous phase and solid 1 after filtration; wash the wall of the reaction kettle, the agitator and the pipeline in the kettle with absolute ethanol and acetone successively, and filter the obtained mixture to obtain the organic phase 1 and solid 2 Add dichloromethane to the water phase and extract to obtain dichloromethane soluble part, which is obtained by rotary evaporation at 40°C to obtain oil 1; solid 1 is washed ...

Embodiment 2

[0022] Under the condition of not adding hydrogen donor, the oil production rate of biomass material catalytic liquefaction to prepare bio-oil was investigated;

[0023] Add 15g of corn stalk powder, 0.3g of NiS-MoS, 0g of aluminum powder, and then add 150mL of deionized water, mix evenly and seal the reactor; before each experiment, the temperature is purged with high-purity nitrogen (99.99%) for 5 minutes to remove the air. The rotating speed of the magnetic stirrer was set at 100r / min and gradually increased to 300r / min; the temperature in the kettle was set at 370°C, and the reaction residence time was set at 60min. After the reaction, the jacket was removed, cooled to room temperature, and the composition of the gas was measured by an infrared online gas analyzer, and then the reactor was opened. Pour out the solid-liquid mixture in the kettle, and obtain the aqueous phase and solid 1 after filtration; wash the wall of the reaction kettle, the agitator and the pipeline in...

Embodiment 3

[0025] Add 15g of corn stalk powder, 0.3g of NiS-MoS, 1.5g of aluminum powder, and then add 150mL of deionized water, mix well and then seal the reaction vessel; before each experiment, purging with high-purity nitrogen (99.99%) for 5 minutes to remove air, . The rotating speed of the magnetic stirrer was set at 100r / min and gradually increased to 300r / min; the temperature in the kettle was set at 370°C, and the reaction residence time was set at 60min. After the reaction, the jacket was removed, cooled to room temperature, and the composition of the gas was measured by an infrared online gas analyzer, and then the reactor was opened. Pour out the solid-liquid mixture in the kettle, and obtain the aqueous phase and solid 1 after filtration; wash the wall of the reaction kettle, the agitator and the pipeline in the kettle with absolute ethanol and acetone successively, and filter the obtained mixture to obtain the organic phase 1 and solid 2 Add dichloromethane to the water ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com