Magnetohydrodynamic electrodeposition method for preparing high-resolution alpha radiation source

A technology of magnetohydrodynamics and α-radiation source, applied in electrolysis components, electrolysis process, cells, etc., can solve the problem of low energy resolution, achieve precise control of electrode spacing, accurate and convenient control of safe operation, and convenient control of anode speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

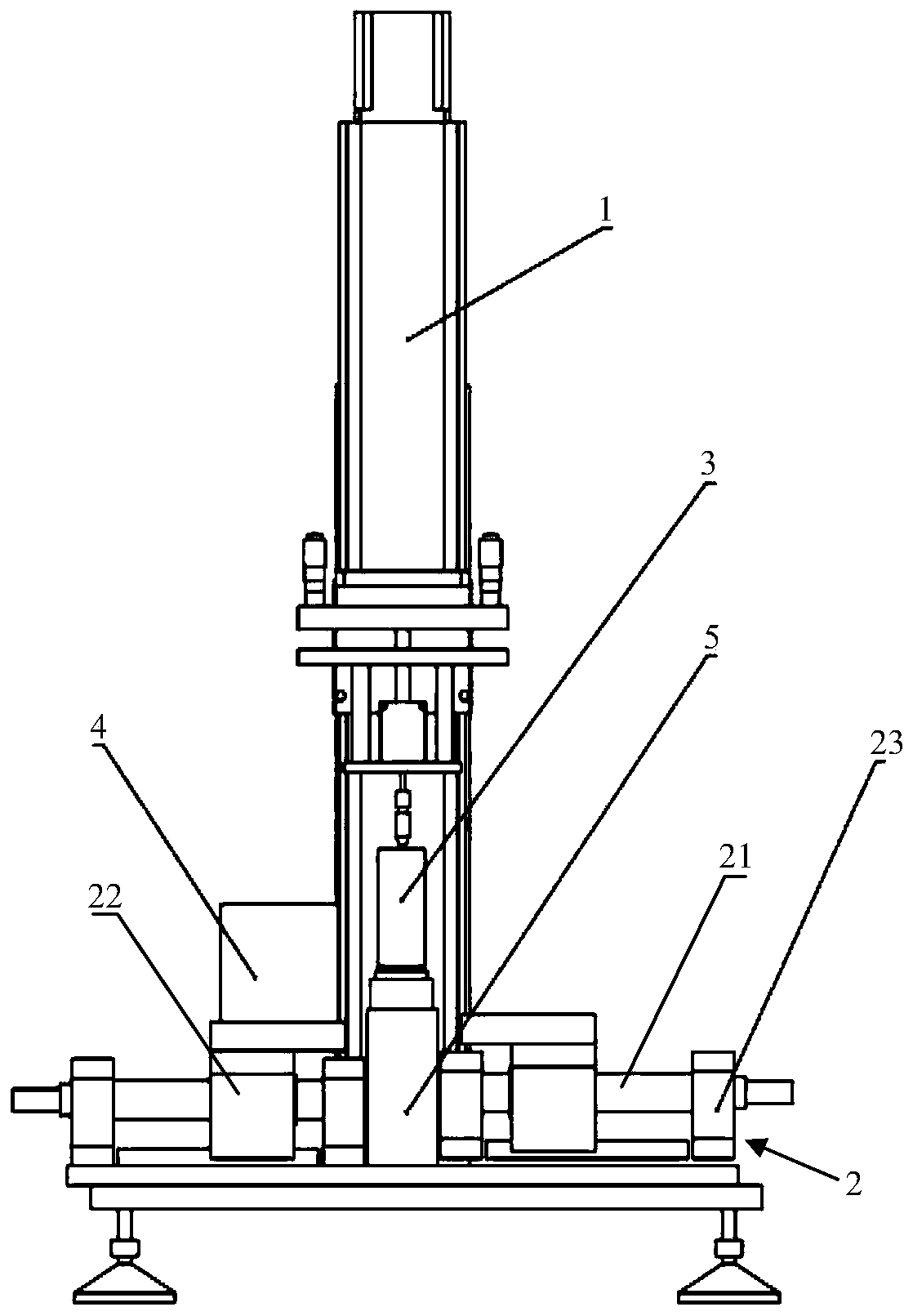

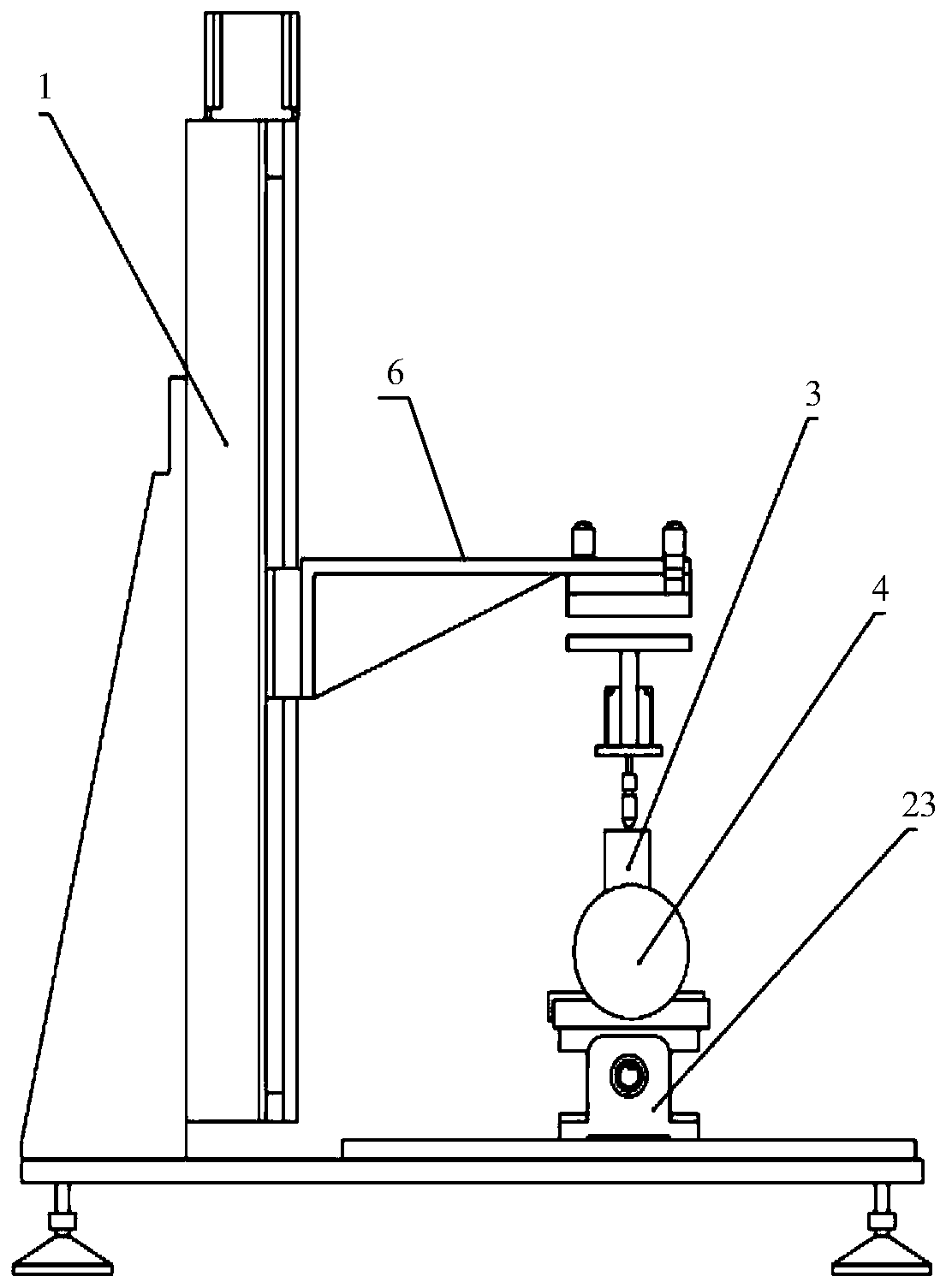

preparation example Construction

[0027] In the magnetohydrodynamic electrodeposition method for preparing a high-resolution alpha radiation source provided by the present invention, a permanent magnet is placed outside the deposition tank, and a magnetic field is applied to the deposition system. During the deposition process, a magnetic field and an electric field coexist to generate a The Lorentz force perpendicular to the direction of the magnetic field and the electric field, the existence of this force can accelerate the liquid phase mass transfer inside the deposition liquid, reduce the thickness of the cathode diffusion layer, and can significantly improve the deposition rate while increasing the deposition efficiency. source resolution.

[0028] The magnetohydrodynamic electrodeposition method for preparing a high-resolution alpha radiation source mainly includes the following steps:

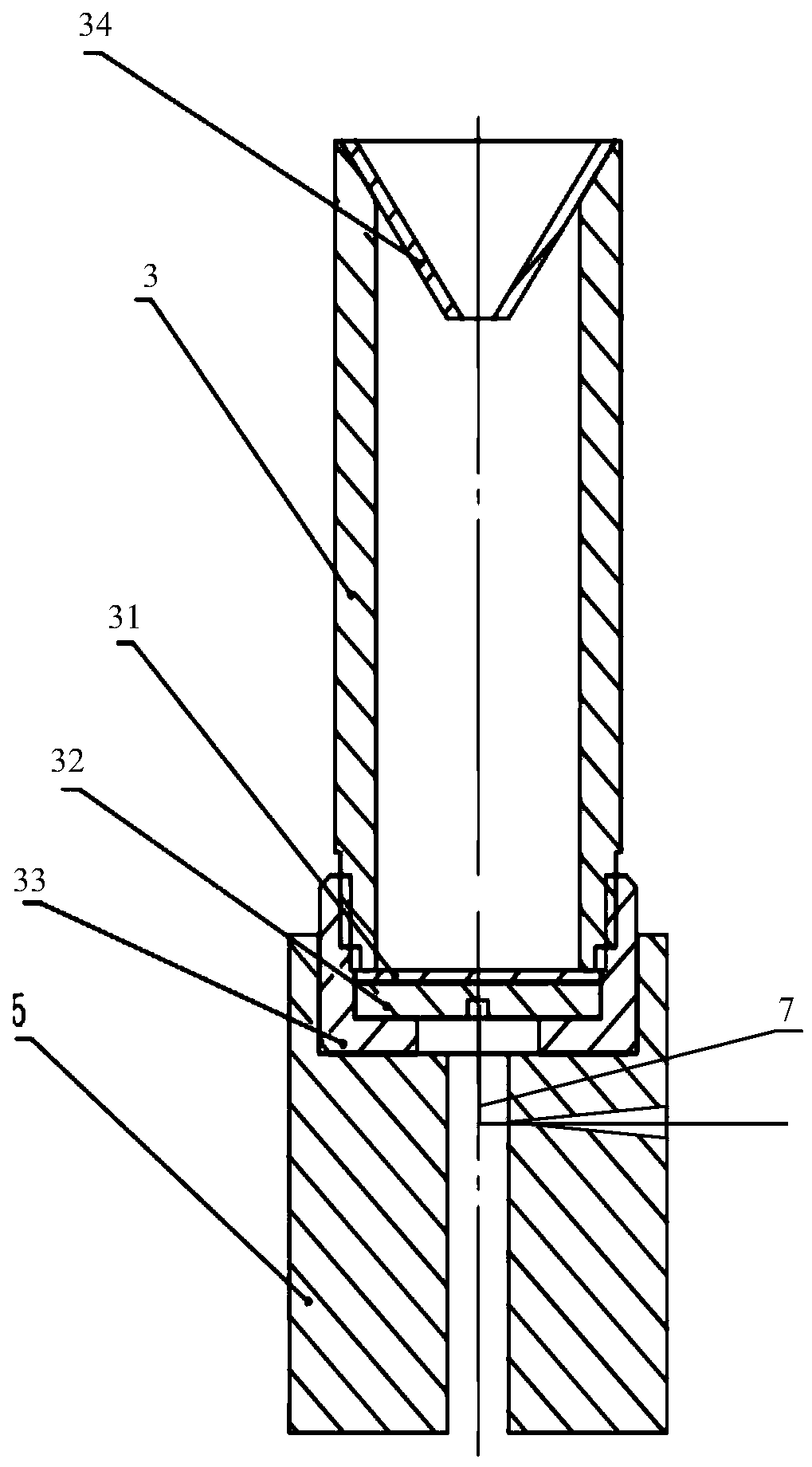

[0029] (1) A permanent magnet capable of applying a magnetic field to the deposition system is provided outside the d...

Embodiment 1

[0043] This embodiment provides a specific MHD electrodeposition method for preparing a high-resolution alpha radiation source, which can be carried out as follows.

[0044] (1) Pretreatment of cathode deposition source sheet

[0045] Clean the stainless steel deposition source piece that has been mechanically polished to remove scale, first with a small amount of decontamination powder, then with deionized water, then with a small amount of sodium carbonate, and then with deionized water, and so on until the surface of the cathode is uniform. until the water film. After cleaning with absolute ethanol, store it in absolute ethanol until use. The diameter of the cathode deposition source sheet is 24 mm, and the diameter of the active area during deposition is 20 mm.

[0046] (2) Preparation of electrolyte

[0047] Prepare an ammonium sulfate solution with a concentration of 0.5 mol / L, adjust its pH value in the range of 2-2.5 with a (1+10) sulfuric acid solution, and use it ...

Embodiment 2

[0059] The magnetohydrodynamic electrodeposition method for preparing a high-resolution α-radiation source in this embodiment is basically the same as the process of Example 1. The difference from Example 1 is that the anode rotation speed is constant at 40r / min, and the anode and cathode deposit the source sheet The distance between them is fixed at 9mm, and the added nuclide is that of the nitric acid system. 238 U solution. Apply permanent magnets symmetrically on both sides of the deposition tank, the magnetic flux density of the two permanent magnets is 0.7T, and the distance between the center of the cathode deposition source sheet and the center of the axial surface of the permanent magnets on each side is 14mm. The device is left-right symmetrical, not only can apply magnetic field symmetrically on both sides of the deposition tank, but also can conveniently adjust the distance between the permanent magnet and the deposition tank, so as to realize the comprehensive stu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic energy product | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com