Graphene polymer fiber and preparation method thereof

A graphene and polymer technology, applied in the field of fiber processing, to achieve the effect of enhancing the siphon effect, broad application prospects, and soft hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

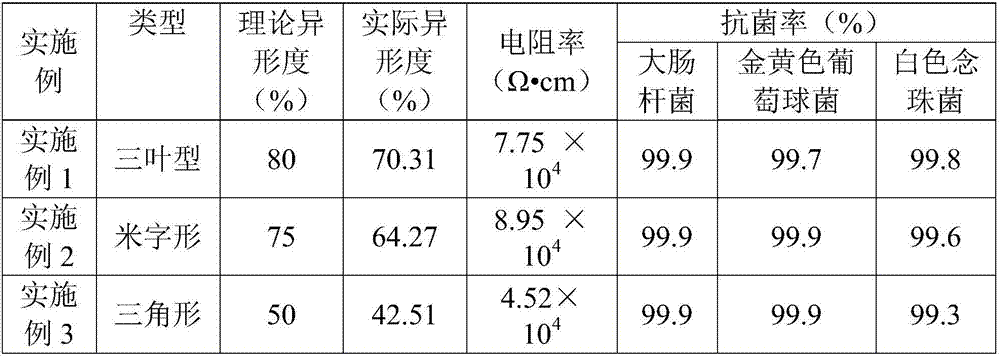

Embodiment 1

[0066] Preparation of high profiled trilobal polyamide 6 / graphene conductive fiber

[0067] After the biomass graphene and polyamide 6 chips with an average particle diameter of 300nm are dried separately, the coupling agent is added, mixed in a kneader at high speed, and then the dispersant is added, and after further mixing, it is cooled to room temperature, and the Graphene powder and polyamide 6 slices were blended and granulated. The temperature of each zone of the screw was 150°C, 240°C, 242°C, 242°C, 240°C, respectively. Polyamide 6 / graphene with a graphene content of 20wt% was prepared. Masterbatch, in the masterbatch, the dispersant content is 2wt%, and the coupling agent content is 1.0wt%.

[0068] The polyamide 6 / graphene masterbatch and polyamide 6 chips are weighed and mixed according to a mass ratio of 1:1 as the main component; water-soluble polyester chips are used as the secondary component. Vacuum drum drying oven is used for drying, and the moisture content of s...

Embodiment 2

[0075] Preparation of high profiled rice-shaped polyamide 6 / graphene conductive fiber

[0076] After the biomass graphene and polyamide 6 chips with an average particle diameter of 300nm are dried separately, the coupling agent is added, mixed in a kneader at high speed, and then the dispersant is added, and after further mixing, it is cooled to room temperature, and the Graphene powder and polyamide 6 chips were blended and granulated. The temperature of each zone of the screw was 150°C, 240°C, 242°C, 242°C, 240°C, respectively. Polyamide 6 / graphene with a graphene content of 30wt% was prepared. Masterbatch, in the masterbatch, the dispersant content is 3wt%, and the coupling agent content is 1.5wt%.

[0077] The polyamide 6 / graphene masterbatch and polyamide 6 chips are weighed and mixed according to a mass ratio of 1:2 as the main component; water-soluble polyester chips are used as the secondary component. Vacuum drum drying oven is used for drying, and the moisture content of...

Embodiment 3

[0085] Preparation of highly profiled regular triangle polyamide 6 / graphene conductive fiber

[0086] After the biomass graphene and polyamide 6 slices with an average particle diameter of 300nm are dried separately, the coupling agent is added, mixed in a kneader at high speed, and then the dispersant is added, and after further mixing, it is cooled to room temperature, and the Graphene powder and polyamide 6 slices were blended and granulated. The temperature of each zone of the screw was 150°C, 240°C, 242°C, 242°C, 240°C, respectively. Polyamide 6 / graphene with a graphene content of 40wt% was prepared. Masterbatch, in the masterbatch, the dispersant content is 4wt%, and the coupling agent content is 2wt%.

[0087] The polyamide 6 / graphene masterbatch and polyamide 6 chips are weighed and mixed according to a mass ratio of 1:3 as the main component; water-soluble polyester chips are used as the secondary component. Vacuum drum drying oven is used for drying, and the moisture con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com