A process for repairing mercury-containing wastewater

A waste water and process technology, applied in the direction of water pollutants, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the effluent concentration is difficult to meet the discharge standard, the concentration of mercury ions cannot be reduced very low, and waste water treatment Incomplete and other problems, to achieve the effect of improving the adhesion of bacterial strains, reducing the amount of sludge produced, and reducing the availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A process for repairing mercury-containing wastewater, which includes the following steps: 1) pretreatment: mercury-containing wastewater is filtered and precipitated to remove large particles and flocs, and then adjust the pH to 6.5-7.2; 2) biological treatment: pretreatment The final wastewater enters the bioremediation tank, and the compound bacterial agent is added according to the amount of 2g per cubic meter of wastewater, and the treatment time is 96 hours.

[0031] The preparation method of described composite bacterial agent comprises the steps:

[0032] 1) The fermentation broth of Pseudomonas putida, Bacillus licheniformis, Enterobacter cloacae, Sporospora thermophila and Bacillus cereus in a volume ratio of 3:3:2:2:1 Mix evenly to obtain a mixed fermentation liquid, and then concentrate to one-fifth of the original volume to obtain a concentrated bacterial liquid; the fermentation liquid of Pseudomonas putida, Bacillus licheniformis, Enterobacter cloacae Th...

Embodiment 2

[0037] A process for repairing mercury-containing wastewater, which includes the following steps: 1) pretreatment: mercury-containing wastewater is filtered and precipitated to remove large particles and flocs, and then adjust the pH to 6.5-7.2; 2) biological treatment: pretreatment The final waste water enters the bioremediation pool, and the compound bacterial agent is added according to the amount of 3g per cubic meter of waste water, and the treatment time is 72 hours.

[0038] The preparation method of described composite bacterial agent comprises the steps:

[0039] 1) The fermentation broth of Pseudomonas putida, Bacillus licheniformis, Enterobacter cloacae, Sporospora thermophila and Bacillus cereus in a volume ratio of 5:5:3:3:2 Mix evenly to obtain a mixed fermentation liquid, and then concentrate to one-fifth of the original volume to obtain a concentrated bacterial liquid; the fermentation liquid of Pseudomonas putida, Bacillus licheniformis, Enterobacter cloacae ...

Embodiment 3

[0044] Gradient test determines the amount of compound bacterial agent added:

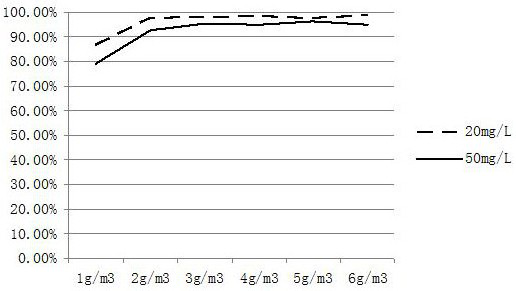

[0045] Set up two groups: Hg 2+ The concentration is 20mg / L and Hg 2+ The concentration is 50mg / L. Treatment process is with reference to embodiment 1; Mercury degradation rate=(Hg before processing 2+ Content - Hg after treatment 2+ content) / Hg before treatment 2+ Content × 100%. attached figure 1 In the process, multiple gradient tests of the addition amount of compound bacteria were set up, and it was found that at 1g / m 3 up to 2g / m 3 , Hg 2+ The removal effect is obviously improved, but 3g / m 3 After, Hg 2+ There is no obvious change, so the best addition amount is 2-3g / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com