Preparation method of zinc oxide modified aramid fiber two-bath dip solution

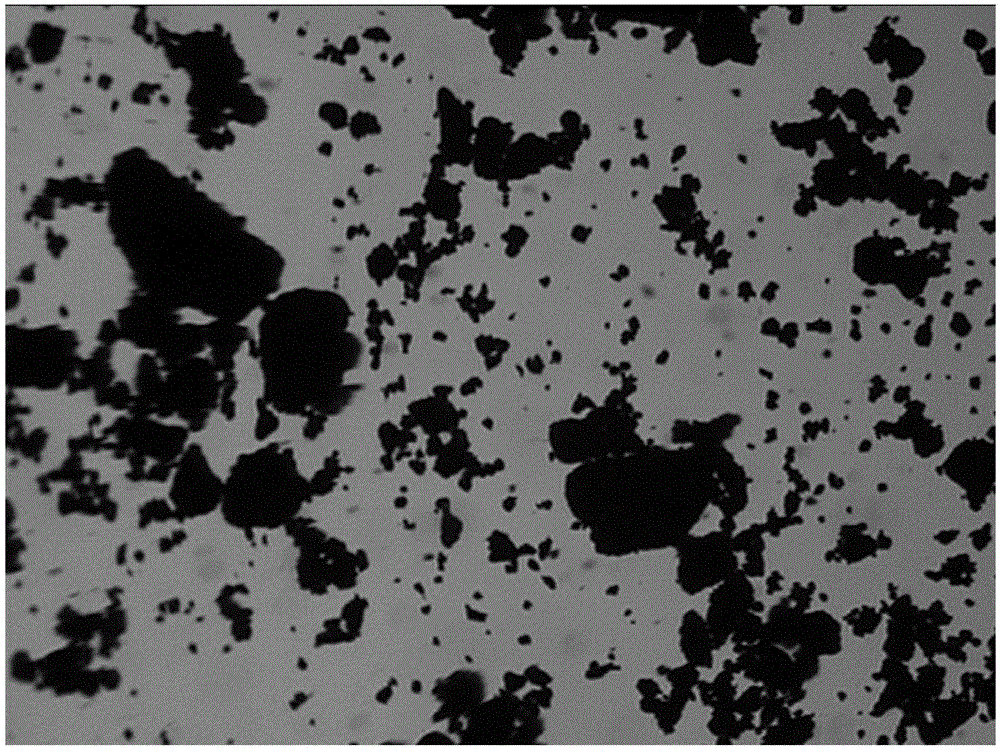

A zinc oxide modified, aramid fiber technology, applied in fiber type, fiber treatment, textile and papermaking, etc., can solve the problems of uneven dispersion, poor stability, easy agglomeration of nano-zinc oxide, and achieve uniform particle size distribution, Good stability and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

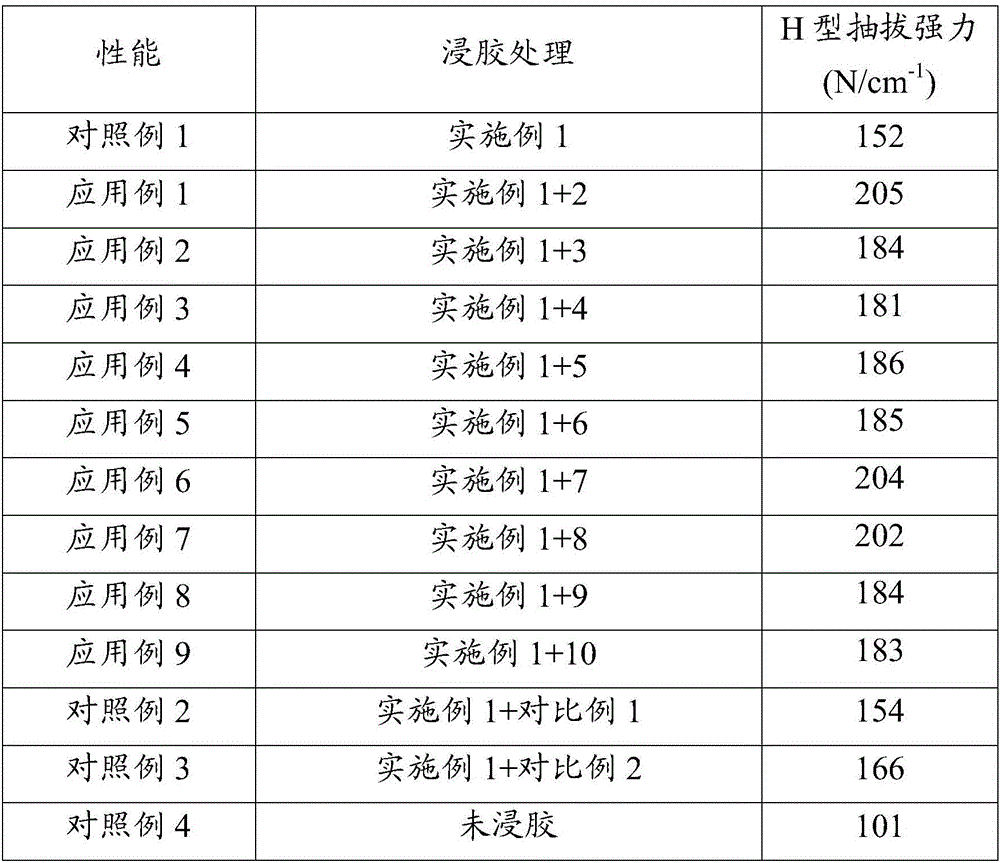

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of aramid fiber one-bath dipping solution

[0038] First, mix E-44 (6101) type epoxy resin (50 parts) and deionized water (4275 parts) at 22°C, add 270 parts of diphenylmethane diisocyanate and stir evenly, then add 400 parts of deionized water Stir evenly to obtain a one-bath dipping solution for the aramid fibers.

Embodiment 2

[0039] Embodiment 2: Preparation of aramid fiber two-bath dipping solution

[0040] (1) Dissolve 1 part of 1799 type polyvinyl alcohol in 100 parts of deionized water, and stir in 1 part of Tween-80 emulsifier for 10 minutes; add 1 part of 30nm zinc oxide and stir for 10 minutes to become a dispersion; add 5.33 Parts of diphenylmethane diisocyanate, 6 parts of 600-type polyethylene glycol, 0.02 parts of triethylenediamine, react at 40°C for 30 minutes; then add 0.5 parts of ethylene glycol, react at 75°C for 60 minutes, and cool to room temperature to obtain Modified zinc oxide dispersion.

[0041] (2) Mix 6 parts of butylpyridine latex with 0.95 parts of deionized water at 23 ° C, add 5.7 parts of resorcinol-formaldehyde resin solution and stir evenly, then add 0.05 parts of deionized water and stir evenly, then add 0.24 parts Ammonia water (mass fraction 25%), 1 part of isocyanate, 1.2 parts of modified zinc oxide dispersion and 0.7 part of deionized water were stirred even...

Embodiment 3

[0042] Embodiment 3: Preparation of aramid fiber two-bath dipping solution

[0043] Prepare according to Example 2, only change the mass ratio of butylpyridine latex to water in step (2) to 3 / 1, and obtain the aramid fiber two-bath dipping solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com