Visible infrared broad band absorber and preparation method thereof

An absorber and broadband technology, applied in the field of visible to infrared broadband absorber and its preparation, can solve the problems of low efficiency, high cost, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

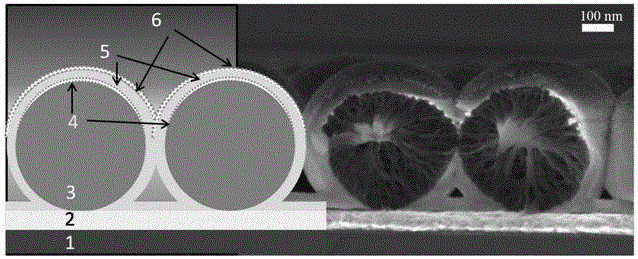

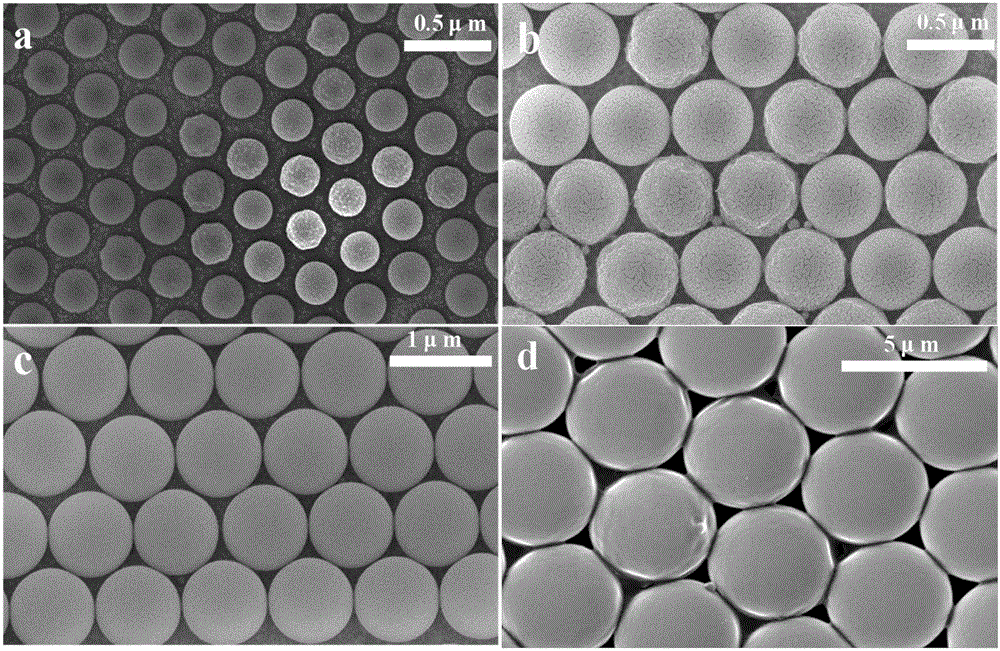

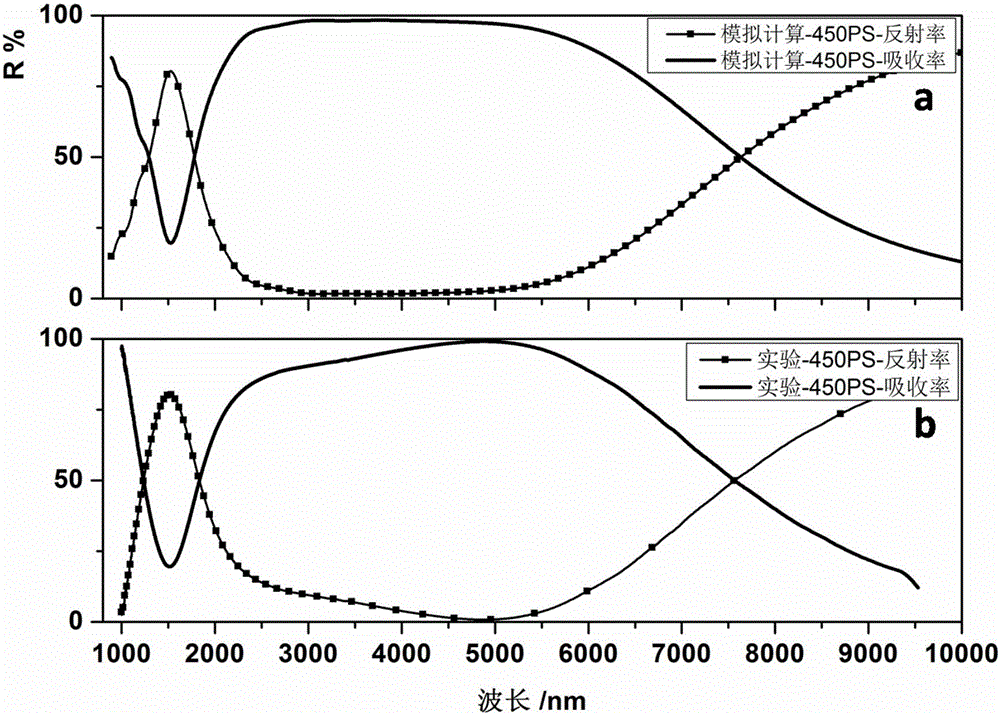

Embodiment 1

[0020] A 100nm gold (Au) thin film was deposited on a silicon substrate by thermal evaporation, and a monolayer of PS balls was formed on the film by self-assembly of polystyrene (PS) balls. The PS spheres we use are 10 wt% aqueous solutions of polystyrene spheres produced by Thermo Scientific. The diameter of PS pellets is 400 nm. Then a 5nm gold film is deposited by thermal evaporation, a 10nm zinc oxide film is deposited by metal organic chemical vapor phase, and a 5nm gold film is deposited on the outermost layer by thermal evaporation. The sample is tested, and the obtained absorption spectrum is greater than 90% at 1.5-2.4 μm, the peak absorption rate (98%), and the full width at half maximum is (0.5 μm).

Embodiment 2

[0022] A 100nm gold thin film is electron beam evaporated on a glass substrate, and a monolayer of PS spheres is formed on the film by self-assembly of polystyrene (PS) spheres. The PS spheres used are 10 wt% aqueous solutions of polystyrene spheres produced by Thermo Scientific. The diameter of PS pellets is 400 nm. Then a 5nm gold film is evaporated by electron beam, a 30nm aluminum oxide film is deposited by atomic layer, and a 5nm gold film is sputtered on the outermost layer by an argon ion beam. The sample is tested, and the obtained absorption spectrum is greater than 90% at 1.5-2.9 μm, the peak absorption rate (95%), and the full width at half maximum is (0.7 μm).

Embodiment 3

[0024] A 100nm gold film was sputtered by argon ion beams on a GaAs substrate, and a monolayer of PS balls was formed on the film by self-assembly of polystyrene (PS) balls. The PS spheres we use are 10 wt% aqueous solutions of polystyrene spheres produced by Thermo Scientific. The diameter of the PS ball is 500nm, which is etched to 300nm by oxygen ion, then a 5nm gold film is sputtered by an argon ion beam, a 100 nm zinc oxide film is magnetron sputtered, and a 5nm gold film is sputtered on the outermost layer by an argon ion beam gold film. The sample is tested, and the obtained absorption spectrum is greater than 85% at 2-3.8 μm, the peak absorption rate (98%), and the full width at half maximum is (0.9 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com